Layered sectioning device for soil body microstructure

A microstructure layer and soil technology, applied in the preparation of test samples, etc., can solve the problems of blurred microstructure imaging, difficulty in collecting 3D microstructure information of soil, and small imaging depth of field, etc., and achieve the effect of compact structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

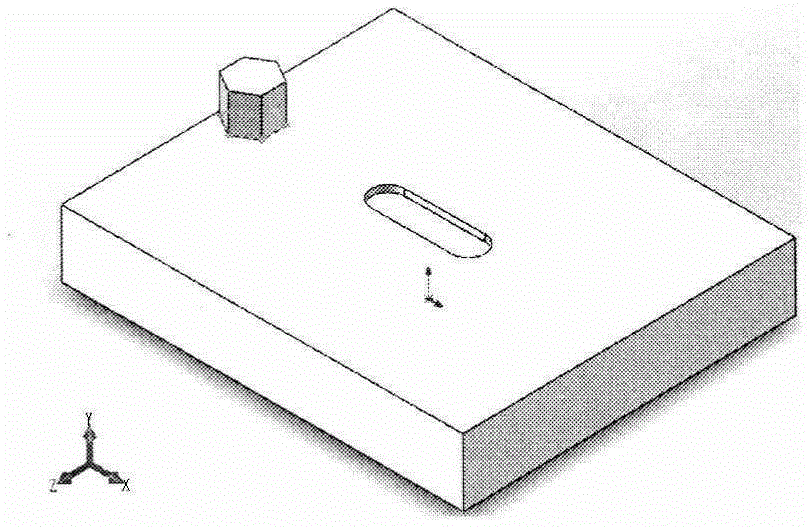

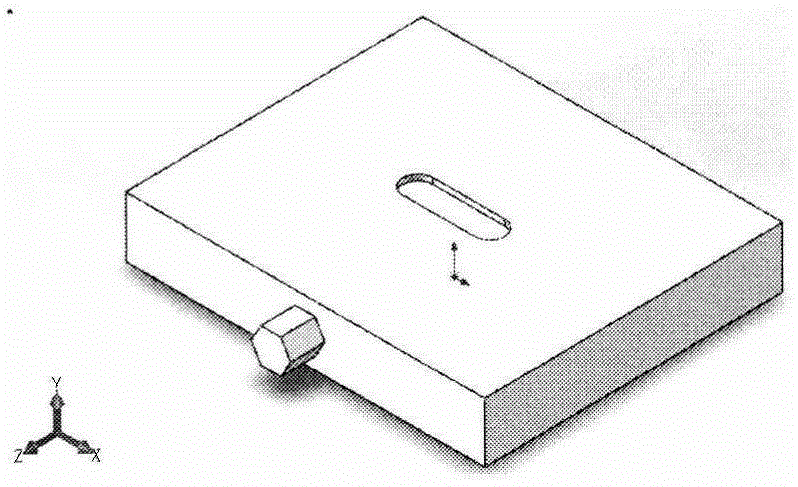

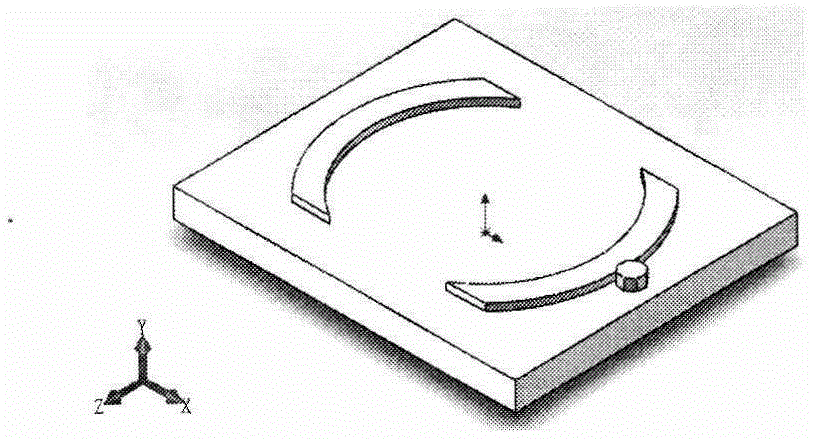

[0030] Attached below Figure 1-13 Describe in detail how to use the present invention. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0031] The assembly process of the device of the present invention is: at first, utilize figure 1 The electric sliding table shown as X-axis, Y-axis, Z-axis precision positioning platform, such as figure 2 , image 3 , Figure 4 shown, with Figure 5 The soil sample holder shown is assembled to form a Figure 6 Assembly shown. followed by Figure 6 The assembly shown is mounted on Figure 7 shown in the chassis base, as Figure 8 shown. Next, install the beam on the upper part of the chassis and place the Figure 9 The high-speed milling mechanism shown is installed and fixed on the beam, and the formed assembly is as follows Figure 10 As shown, its front view is as Figure 11 shown. Finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com