Brushless DC motor with asymmetric winding

A DC motor, asymmetric technology, applied in the shape/style/structure of the winding conductor, etc., can solve the problems of low motor speed adjustment accuracy, low current density, and motor output power limitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

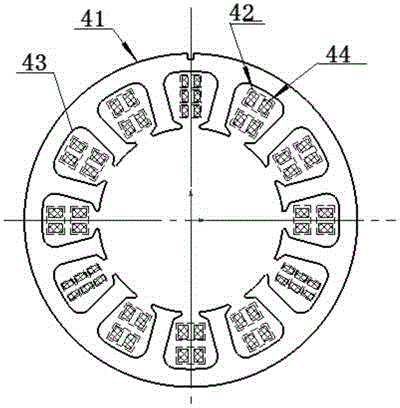

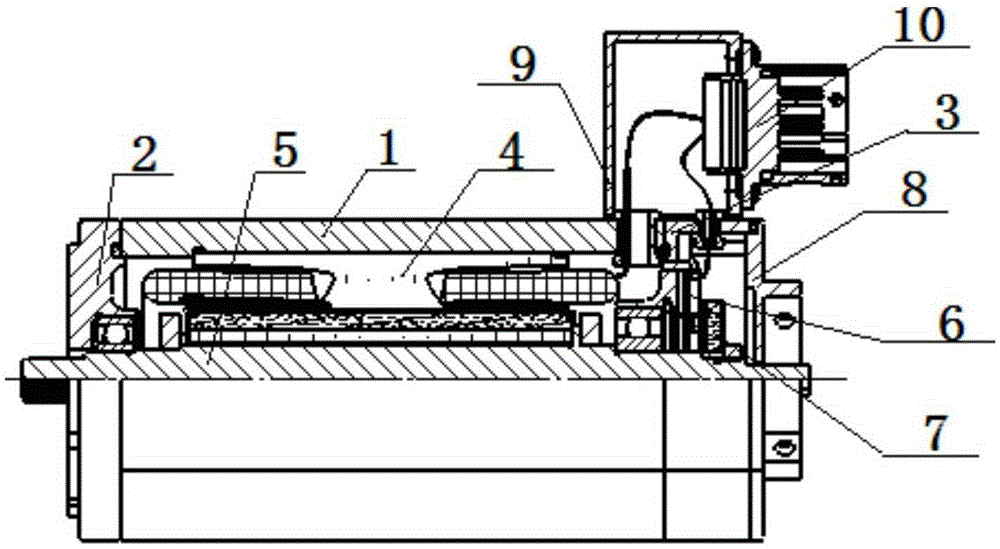

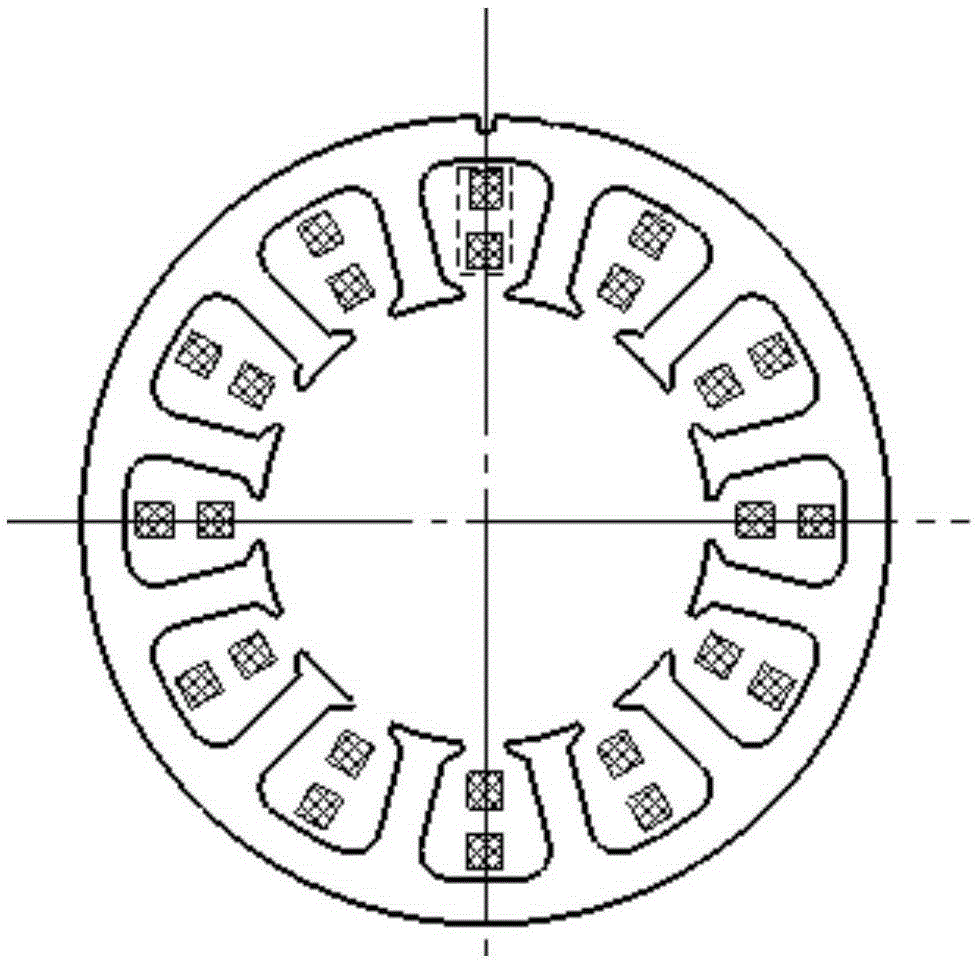

[0016] The brushless DC motor with asymmetric winding is composed as follows: housing 1, front end cover 2, rear end cover 3, stator 4, rotor 5, circuit board assembly 6, sensor rotor 7, sensor rear cover 8, connector base 9 and electrical connector 10; the stator 4 is bonded inside the housing 1, and the stator 4 includes a stator core 41 and a winding 42; the stator core 41 is provided with a stator slot structure 43, and the winding 42 is asymmetrically embedded in the stator slot In the structure 43, the winding 42 is wound by enameled wire 44, the front end cover 2 and the rear end cover 3 are respectively fixedly connected to the two ends of the housing 1, the rotor 5 is connected with the front end cover 2 and the rear end cover 3, the rotor assembly Cooperate with the front end cover and the rear end cover through the bearing. The circuit board assembly is fixed on the rear end cover through screws, and the sensor rotor 7 is connected with the rotor 5 through nuts. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com