Preparation of tomato soilless culture substrate by using cattle and sheep manure

A soilless culture substrate, cattle and sheep dung technology, applied in soilless culture, cultivation, culture medium and other directions, can solve the problems of insufficient fermentation maturity, low substrate bulk density, etc., to reduce production costs, improve yield and quality, accelerate The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment utilizes cattle and sheep manure to prepare tomato soilless culture substrate by the following steps:

[0024] 1. Fermentation of cow dung and sheep dung: keep the humidity of cow dung and sheep dung at 60%, add 3% and 3.5% cotton straw by volume to adjust the carbon-nitrogen ratio, mix evenly, The dose of microbial fermentation bacteria used is 0.5kg, and the bottom layer is covered with plastic to isolate it from the soil. Pile the material into a body shape, cover it with a canopy film, and carry out fermentation. The material is turned every 10 days, and it is replenished every 20 days or so. The whole process takes 50 days.

[0025] 2. Fermentation of cotton stalks: first cut the cotton stalks into 1.5cm long and short pieces, soak them in water to keep the humidity at 60%, use 0.5kg of microbial fermentation bacteria per square meter, pile them into piles, and pile the materials into 1.5m high piles , cover the canopy film, carry out fermen...

Embodiment 2

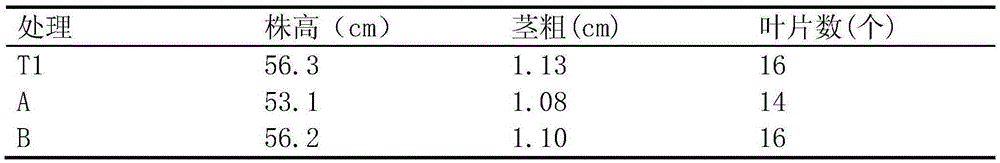

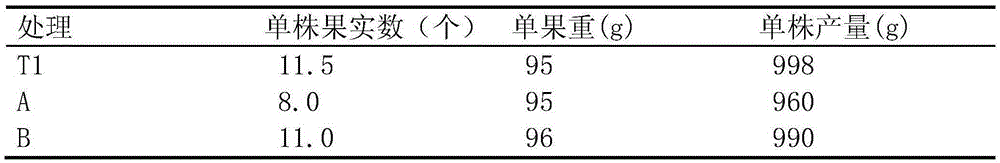

[0031] In this example, cattle and sheep manure is used to prepare tomato soilless culture substrate. The substrate prepared is the same as that in Example 1 (T1), except that the tomato variety "Oudi" tomato is used as the test material, and the "rectangular" trough cultivation is used. A (local traditional formula matrix) and formula B (commercial matrix) were used as controls, and the effectiveness of using cattle and sheep manure to prepare tomato soilless cultivation matrix in this example was studied by measuring the growth status of tomato plants, fruit quality and yield. The experiment adopted a single factor randomized block design, with 20 tomato plants in each treatment, repeated three times. Select tomato seedlings that grow robustly and uniformly, have complete root systems, and are free from diseases and insect pests, and transplant them. Irrigate moderately to keep the substrate moist. Except for the cultivation medium, other external environmental conditions w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com