Baker and its control process

A technology for drying buns and burners, which is used in manufacturing tools, casting melt containers, metal processing equipment, etc. Burning effect, possibility reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

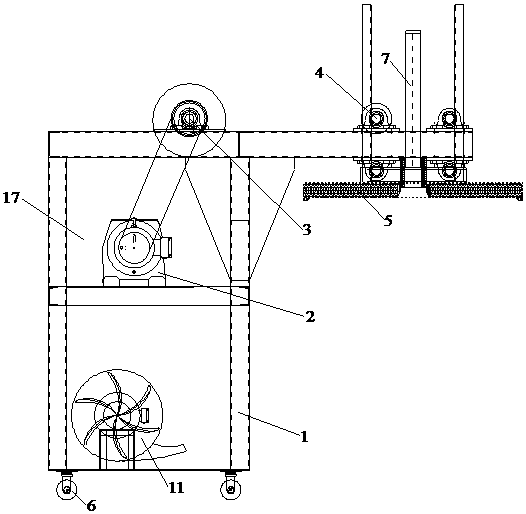

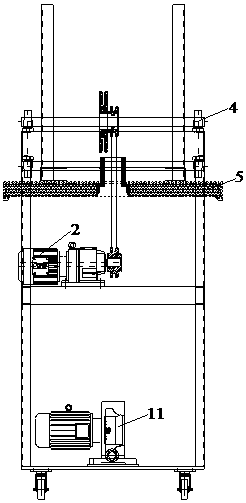

Embodiment 1

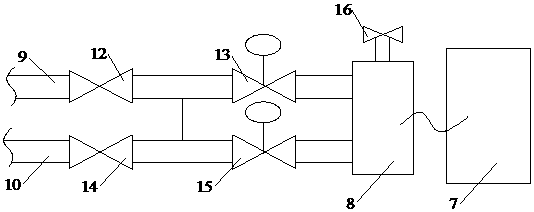

[0042] Step 1. Ignition process

[0043] Open the natural gas on-off valve 12 to regulate the flow of natural gas through the natural gas flow regulating valve 13;

[0044] Open the combustion-supporting air switch valve 14, and adjust the flow rate of the combustion-supporting air through the combustion-supporting air flow regulating valve 15;

[0045] Turn on the ignition button on the burner 7, the ignition is successful, then turn on the combustion-supporting fan 11, and start the proportional control valve 16 to ensure that the flow rate of the mixed gas is 15m 3 / h: Adjust the ratio of natural gas and combustion-supporting air through the combustion of the burner 7, so that the ratio of natural gas and combustion-supporting air is suitable to achieve the best combustion effect;

[0046] If ignition fails, close the natural gas on-off valve 12 and the combustion-supporting air switch-off valve 14 immediately, the residual gas inside the natural gas pipeline 9 and the com...

Embodiment 2

[0052] Step 1. Ignition process

[0053] Open the natural gas on-off valve 12 to regulate the flow of natural gas through the natural gas flow regulating valve 13;

[0054] Open the combustion-supporting air switch valve 14, and adjust the flow rate of the combustion-supporting air through the combustion-supporting air flow regulating valve 15;

[0055]Turn on the ignition button on the burner 7, the ignition is successful, then turn on the combustion-supporting fan 11, and start the proportional control valve 16 to ensure that the flow rate of the mixed gas is 17m 3 / h: Adjust the ratio of natural gas and combustion-supporting air through the combustion of the burner 7, so that the ratio of natural gas and combustion-supporting air is suitable to achieve the best combustion effect;

[0056] If the ignition fails, immediately close the natural gas on-off valve 12 and the combustion-supporting air on-off valve 14, and the residual gas inside the natural gas pipeline 9 and the ...

Embodiment 3

[0059] Step 1. Ignition process

[0060] Open the natural gas on-off valve 12 to regulate the flow of natural gas through the natural gas flow regulating valve 13;

[0061] Open the combustion-supporting air switch valve 14, and adjust the flow rate of the combustion-supporting air through the combustion-supporting air flow regulating valve 15;

[0062] Turn on the ignition button on the burner 7, the ignition is successful, then turn on the combustion-supporting fan 11, and start the proportional control valve 16 to ensure that the flow rate of the mixed gas is 20m 3 / h: Adjust the ratio of natural gas and combustion-supporting air through the combustion of the burner 7, so that the ratio of natural gas and combustion-supporting air is suitable to achieve the best combustion effect;

[0063] If the ignition fails, immediately close the natural gas on-off valve 12 and the combustion-supporting air on-off valve 14, and the residual gas inside the natural gas pipeline 9 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com