Five-axis linkage ultrasonic composite electric spark micro-finish machining numerical control machine tool

A five-axis linkage and CNC machine tool technology, which is applied in the field of compound and micro-special processing, can solve the problems of difficult-to-machine materials and special-shaped surfaces, and achieve the effects of stable feed direction, update, and improved efficiency and precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and description of the accompanying drawings.

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

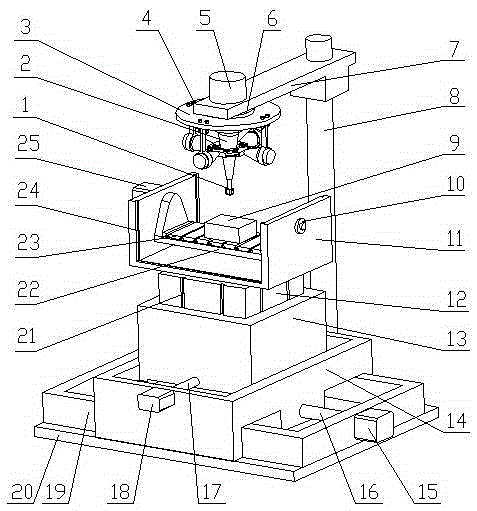

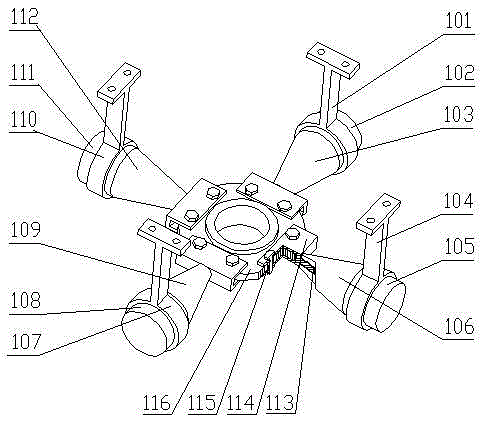

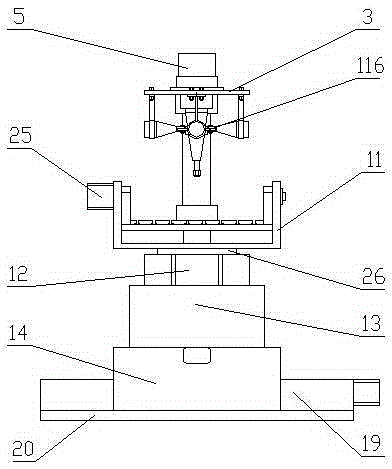

[0028] Five-axis linkage ultrasonic compound EDM micro-finishing CNC machine tool, including tool electrode 1, horn 2, flange plate 116, piezoelectric transducer 5, support plate 3, support frame 7, column 8, base 20, A To the rotary table mechanism 22, to the C-directed rotary liquid tank mechanism 11, to the Z-axis lifting platform mechanism 12, to the Y-axis sliding mechanism 17, and to the X-axis sliding saddle mechanism 14. The upper end of the tool electrode 1 is installed in the threaded hole at the bottom of the horn 2 directly above it by screws, and the neck butt welding flange 116 is sleeved at the vibration node of the horn 2 .

[0029] The piezoelectric transducer 5 is arranged above the horn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com