Preparation method of luggage shell

A shell and bag technology, applied in the field of bags, can solve the problems of poor shaping strength, insufficient rigidity, and easy breakage, and achieve the effects of good impact resistance, good molding quality, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

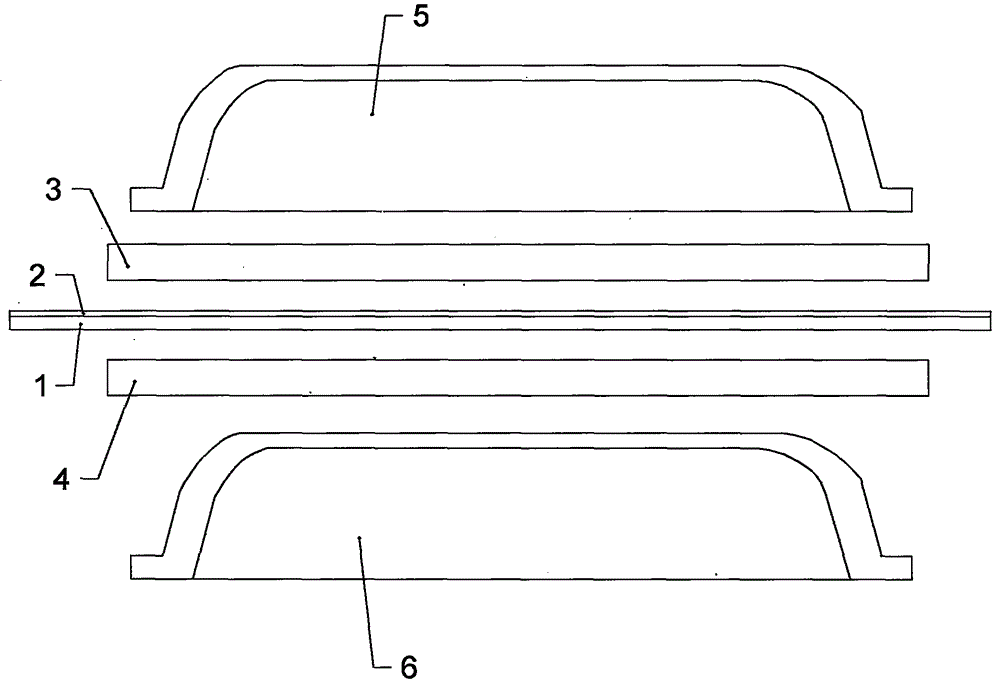

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0016] The following reference figure 1 and figure 2 The present invention will be described.

[0017] A method for preparing a case shell, comprising the steps of:

[0018] (1) A plastic plate 1 with a thickness of 5-9mm is selected as the skeleton, and a cloth 2 with a melting point higher than 200°C is selected as the outer layer; the melting point of the cloth is higher than 200°C to prevent the cloth from being damaged during the hot pressing process.

[0019] (2) Lay the plastic plate 1 and the fabric 2 together and heat-compress and compound them through a hot-press laminating machine to obtain a composite plate. The thickness tolerance of the composite plate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com