Ethylene spherical tank cooling depressurizing method

An ethylene spherical tank and ethylene technology, which is applied to tank cars, transport passenger cars, railway car body parts, etc., can solve the problems of large investment, low cooling efficiency, and slow pressure reduction speed of the gas phase ethylene cooling method, and achieve small investment and high cooling efficiency High, rapid cooling effect of pressure reduction and temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in detail below with specific examples, but these examples do not limit the scope of the present invention.

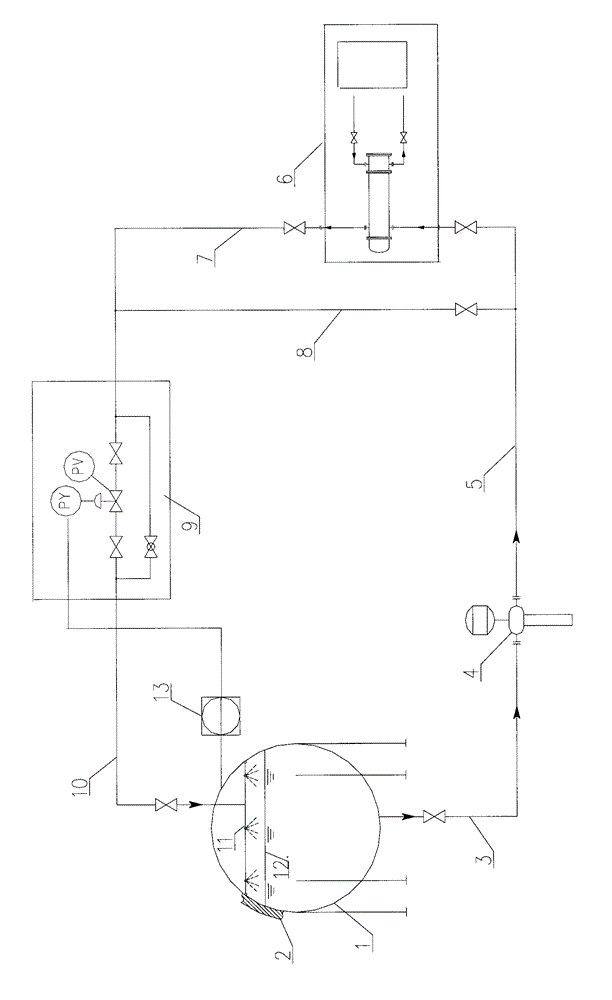

[0039] as attached figure 1 As shown, the specific operation process of a method for cooling and depressurizing an ethylene spherical tank of the present invention is as follows: When the pressure transmitter 13 detects that the pressure of the gas phase ethylene stored in the top of the ethylene spherical tank 1 is too high and alarms, the ethylene transfer pump 4 start up. The liquid phase ethylene at the bottom enters the ethylene transfer pump 4 from the ethylene spherical tank 1 through the pump suction pipe 3 . The liquid-phase ethylene is boosted by the ethylene transfer pump 4 and sent to the circulating refrigeration unit 6 to cool down and become low-temperature liquid-phase ethylene. Sprinkle ring screen pipe 11. The low-temperature liquid-phase ethylene passes through the spray ring screen 11 and becomes a low-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com