Novel strong brine desalting equipment and novel strong brine desalting process

A new type of concentrated brine technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high cost of desalination of concentrated brine, low combustion utilization rate, low efficiency, etc. problem, to achieve the effect of small footprint, fast heating and evaporation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

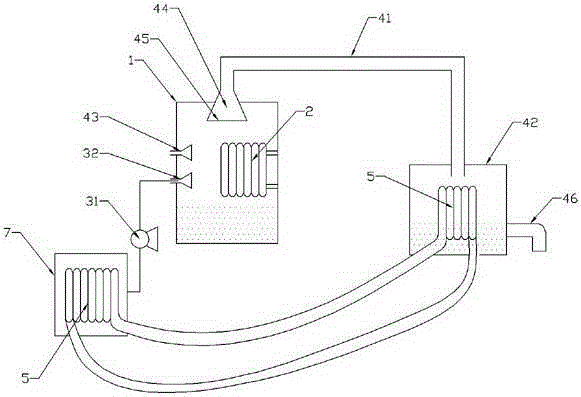

[0022] Such as figure 1 As shown, a new type of concentrated brine desalination equipment includes a water supply atomization mechanism connected in sequence, a vaporization chamber 1 with a high-temperature heating plate 2 inside, a water vapor condensation mechanism, and a serpentine water vapor condensation pipe 5. The water supply mist The condensing mechanism is connected with the external concentrated brine storage 7, and the water vapor condensation mechanism is connected with the external concentrated brine storage 7 through the serpentine water vapor condensation pipe 5. A heat transfer medium is arranged inside the serpentine water vapor condenser tube 5 .

[0023] The vaporization chamber 1 is a corrosion-resistant closed box, and the vaporization chamber 1 is provided with a vacuum pump.

[0024] The high-temperature heating plate 2 is fixedly arranged on the inner wall of the right box of the vaporization chamber 1 and is heated by green energy sources such as so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com