Process method for producing inorganic fiber from red mud

A technology of inorganic fibers and process methods, applied in the manufacture of tools, glass manufacturing equipment, etc., can solve the problems of high production costs, failure to meet the national "rock wool" technical standards, complex processes, etc., and achieve low production costs and social environmental protection Significant benefit and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

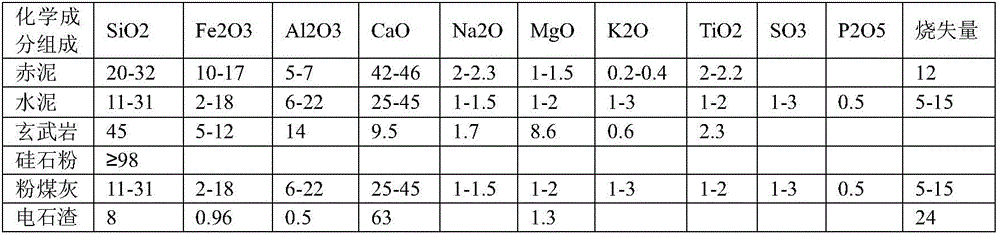

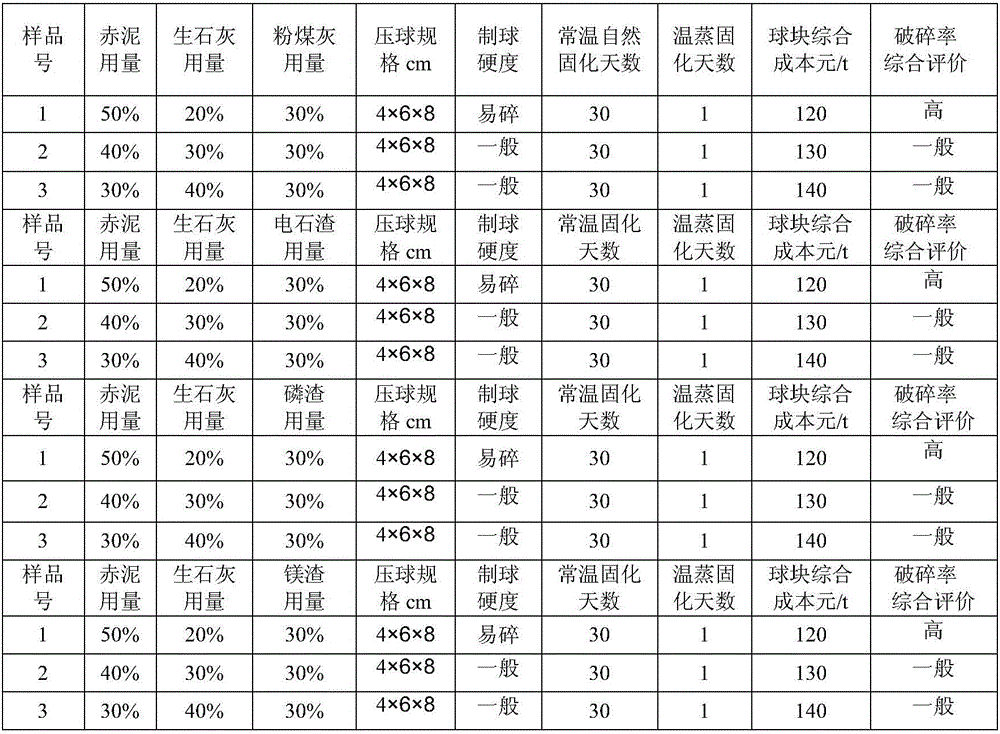

[0017] Red mud is used as the main ingredient, and its water content is controlled at 10-14% before batching. Add cement at a weight ratio of 1:0.1-0.15, add water and stir to mix evenly, and the total water content after mixing is controlled at 8-12%. 325 or 425 Portland cement is used as the curing agent for the cement.

[0018] The mixture is strongly pressed into a ball shape, about 4 x 6 x 8 cm, dried naturally, and solidified to form a ball block material. Then the ball block material, basalt ore block and coke are mixed evenly according to the weight ratio of 3.5:0.1~0.2:1 to form a semi-finished material; the size of the basalt ore block is about 8×10×12cm, and the SiO2 content is 45%. Al2O3 content of 14% or more is used as an acidity coefficient regulator; the coke particle size is 6-10cm, and the calorific value is >7000kca / k.

[0019] Semi-finished materials are melted at a high temperature in a melting furnace, and the temperature during high-temperature melting ...

Embodiment 2

[0023] Red mud is used as the main ingredient, and its water content is controlled at 10-14% before batching. Add cement and silica powder at a weight ratio of 1:0.15:0.1-0.2, add water and mix well, and the total water content after mixing is controlled at 8-0. 12%; the cement adopts 325 or 425 Portland cement, which is used as a curing agent; the silica powder is 325-500 mesh, and the SiO2 content is more than 95%, and is used as an acidity coefficient regulator.

[0024] The mixture is strongly pressed into a ball shape, about 4 x 6 x 8 cm, dried naturally, and solidified to form a ball block material. Then the ball block material and coke are batched according to the weight ratio of 3.5:1, and mixed evenly to form a semi-finished material; the coke particle size is 6-10cm, and the calorific value is >7000kca / k.

[0025] The semi-finished material is melted at high temperature in the melting furnace. The temperature during high-temperature melting is 1550-17000°C, and high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com