Mould-proof exterior wall paint and preparation method

A technology of exterior wall paint and redispersed latex powder, which is applied in the field of wall paint, can solve the problems of poor anti-mildew performance of exterior wall paint, reduced paint film service life, and paint film cracking, etc., and achieves excellent anti-mildew effect, wide Spectral bactericidal ability, the effect of reducing the degree of mold growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

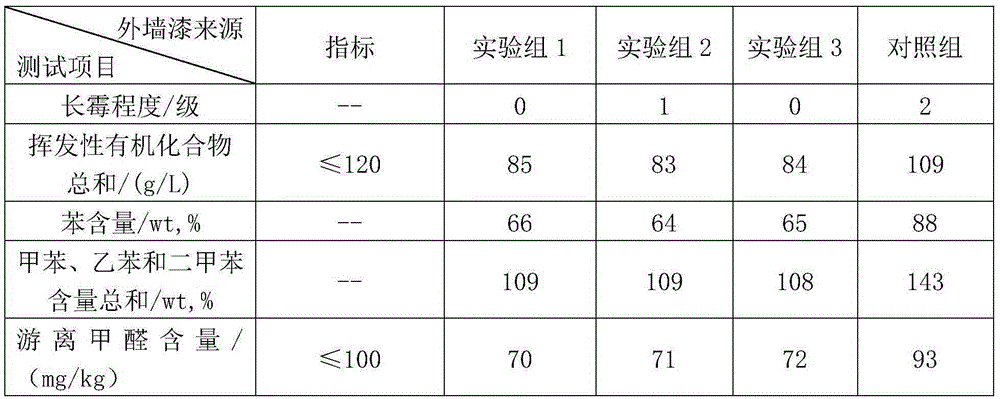

Examples

Embodiment 1

[0037] A mildew-resistant exterior wall paint, which consists of the following components: 9kg of vinyl acetate and ethylene copolymer rubber powder, 6kg of wollastonite powder, 10kg of diatomite, 4kg of 1250-mesh ground calcium carbonate, 5kg of ethylene glycol, 2kg of Multifunctional additive AMP-95, 2kg dispersant, 2.5kg octylphenol polyoxyethylene ether series wetting agent, 1kg water-based acid alcohol resin defoamer, 2kg antifungal agent, 1.5kg anti-settling agent and 40kg water.

[0038] The antifungal agent is a quasi-powder synthesized by doping 0.4kg nanometer silver, 0.8kg nanometer copper and 0.8kg nanometer zinc.

[0039] The preparation method of this mildew-proof exterior wall paint is:

[0040] A. Weigh according to the ratio of raw materials and reserve;

[0041] B. Add water to the mixer, then add diatomaceous earth, wollastonite powder, ground calcium carbonate, ethylene glycol and dispersant in sequence, and stir at 680 rpm for 18 minutes at 32°C;

[0042...

Embodiment 2

[0044]A mildew-resistant exterior wall paint, consisting of the following components: 6kg of vinyl acetate and ethylene copolymer rubber powder, 15kg of wollastonite powder, 5kg of diatomite, 6kg of 1250-mesh ground calcium carbonate, 3kg of ethylene glycol, 5kg of Multifunctional additive AMP-95, 4kg dispersant, 1.5kg octylphenol polyoxyethylene ether series wetting agent, 1kg water-based acid alcohol resin defoamer, 1kg antifungal agent, 0.5kg anti-settling agent and 30kg water.

[0045] The antifungal agent is a quasi-powder synthesized by doping 0.2kg nanometer silver, 0.4kg nanometer copper and 0.4kg nanometer zinc.

[0046] The preparation method of this mildew-proof exterior wall paint is:

[0047] A. Weigh according to the ratio of raw materials and reserve;

[0048] B. Add water to the mixer, then add diatomaceous earth, wollastonite powder, heavy calcium carbonate, ethylene glycol and dispersant in turn, and stir at 680-750 rpm for 12- 18 minutes;

[0049] C. Add ...

Embodiment 3

[0051] A mildew-resistant exterior wall paint, consisting of the following components: 8kg of vinyl acetate and ethylene copolymer rubber powder, 9kg of wollastonite powder, 6kg of diatomite, 5kg of 1250-mesh ground calcium carbonate, 4kg of ethylene glycol, 3kg of Multifunctional additive AMP-95, 3kg dispersant, 2kg octylphenol polyoxyethylene ether series wetting agent, 2kg water-based acid alcohol resin defoamer, 1.2kg antifungal agent, 0.8kg anti-settling agent and 36kg water.

[0052] The antifungal agent is a quasi-powder synthesized by doping 0.24kg nano-silver, 0.48kg nano-copper and 0.48kg nano-zinc.

[0053] The preparation method of this mildew-proof exterior wall paint is:

[0054] A. Weigh according to the ratio of raw materials and reserve;

[0055] B. Add water to the mixer, then add diatomaceous earth, wollastonite powder, ground calcium carbonate, ethylene glycol and dispersant in sequence, and stir at 720 rpm for 15 minutes at 36°C;

[0056] C. Add dispersa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com