Variable-component refrigerant heat pump hot water unit

A heat pump hot water and refrigerant technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of reduced regulation capacity, low refrigerant temperature, and reduced heating performance, so as to improve low-temperature heating capacity , shorten the change time, improve the effect of heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

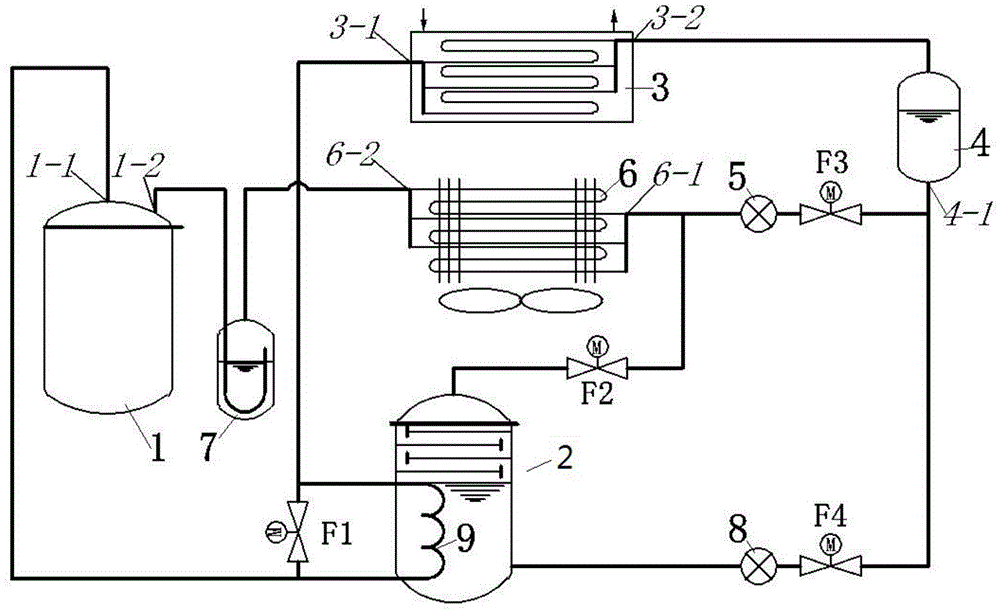

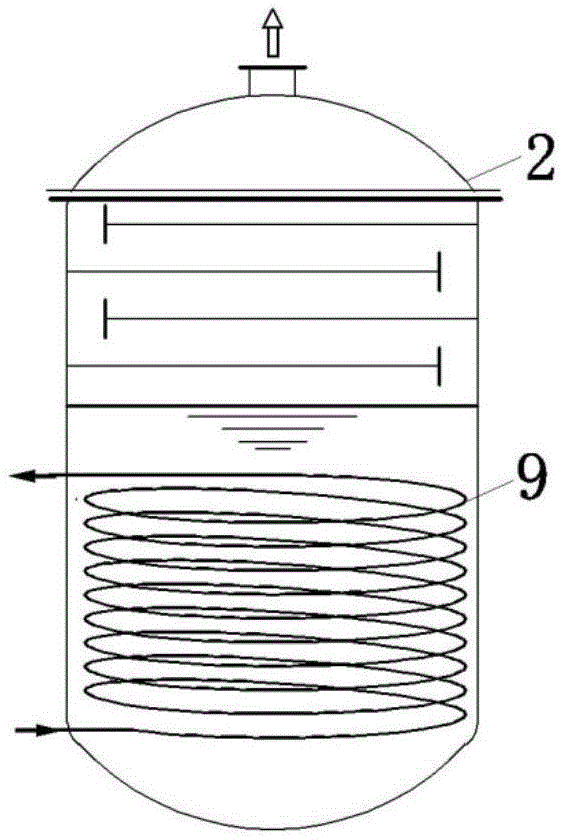

[0018] combine figure 1 , figure 2 , a variable component refrigerant heat pump water heater unit, including a compressor 1 for sucking gaseous refrigerant and compressing it for output, a condensing heat exchanger 3, and a liquid storage tank 4 connected to the condensing heat exchanger 3 , an outdoor heat exchanger 6, a gas-liquid separator 7 connected to the outlet of the outdoor heat exchanger 6, a rectifier 2 filled with a non-azeotropic mixed refrigerant and a disc set inside the rectifier 2 Pipe 9; the outlet of the gas-liquid separator 7 is connected to the compressor inlet 1-2, and the coil pipe 9 and the first solenoid valve F1 are arranged in parallel between the compressor outlet 1-1 and the condensation heat exchanger inlet 3-1; Two parallel branches are arranged between the liquid tank 4 and the outdoor heat exchanger 6, the outlet of the liquid storage tank 4, the third electromagnetic valve F3, the first throttle valve 5, and the inlet of the outdoor heat exc...

Embodiment 2

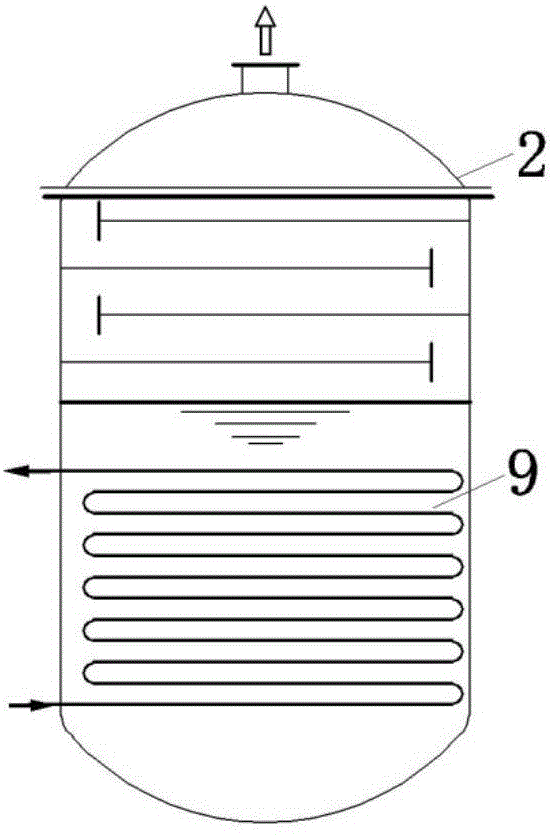

[0028] combine figure 1 , image 3 , a variable component refrigerant heat pump water heater unit, including a compressor 1 for sucking gaseous refrigerant and compressing it for output, a condensing heat exchanger 3, and a liquid storage tank 4 connected to the condensing heat exchanger 3 , an outdoor heat exchanger 6, a gas-liquid separator 7 connected to the outlet of the outdoor heat exchanger 6, the outlet of the gas-liquid separator 7 is connected to the compressor inlet 1-2, and the variable composition refrigerant The heat pump hot water unit also includes a rectifier 2 filled with non-azeotropic mixed refrigerant and a coil 9 arranged inside the rectifier 2; the coil 9 is arranged in parallel with the first electromagnetic valve F1 on the compressor Between the outlet 1-1 and the inlet 3-1 of the condensing heat exchanger; two parallel branches are arranged between the liquid storage tank 4 and the outdoor heat exchanger 6, the outlet of the liquid storage tank 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com