Synthetic diamond heating and power-regulating device

A technology of artificial diamond and power regulator, which is applied in the direction of control/regulation system, non-electric variable control, instrument, etc., can solve the problems of inability to realize remote monitoring, inaccurate temperature, single function of heating power regulator, etc. Intelligent management, precise control parameters, and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

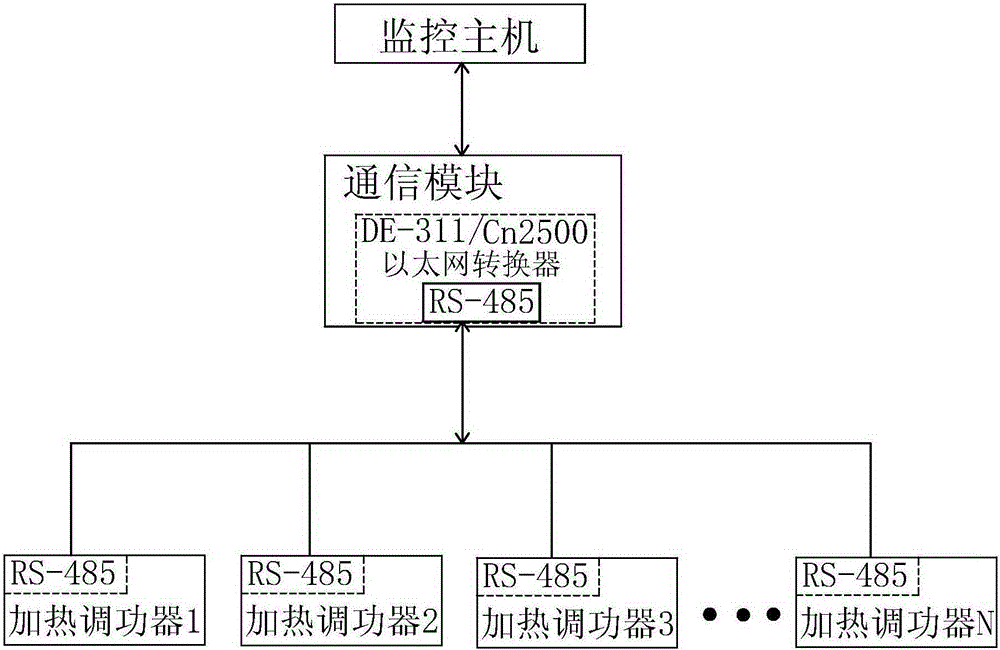

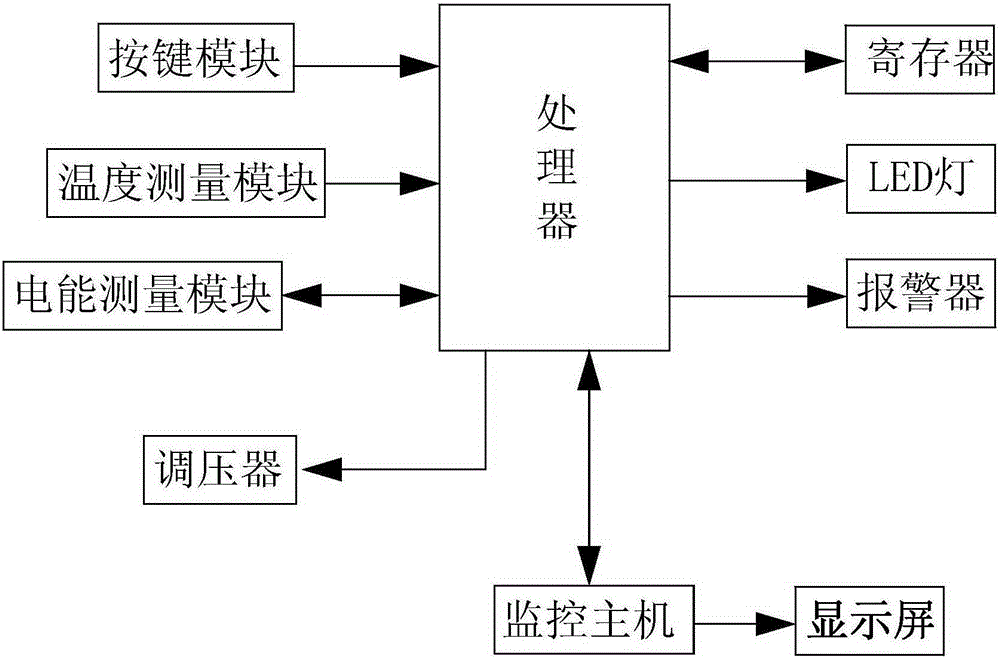

[0025] Such as figure 1 As shown, the artificial diamond heating power regulator includes a control system, a monitoring host and at least one heating power regulator. This embodiment is specifically 1 to N heating power regulators, where N is a positive integer. Each heating power regulator is connected with the monitoring host through the communication module. In this embodiment, the communication module includes a receiver installed on the monitoring host and a transmitter used in conjunction with the receiver and connected to the receiver signal, and the transmitter is mainly installed on each heating power regulator composed of network elements. In this embodiment, the data connection between the monitoring host and each heating power regulator is realized through Ethernet, and of course other wireless connection methods can also be selected. The receiver specifically adopts an Ethernet converter model DE-311 or a serial port Ethernet converter model Cn2500, and the net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com