A sheet metal connection method verified by cae based on design data

A sheet metal and data technology, applied in the field of sheet metal connection based on design data that has passed CAE verification, can solve problems that affect calculation results, easily lose welded parts, increase modeling time, etc., to reduce waste and achieve accurate CAE analysis results Error-free, preventive design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

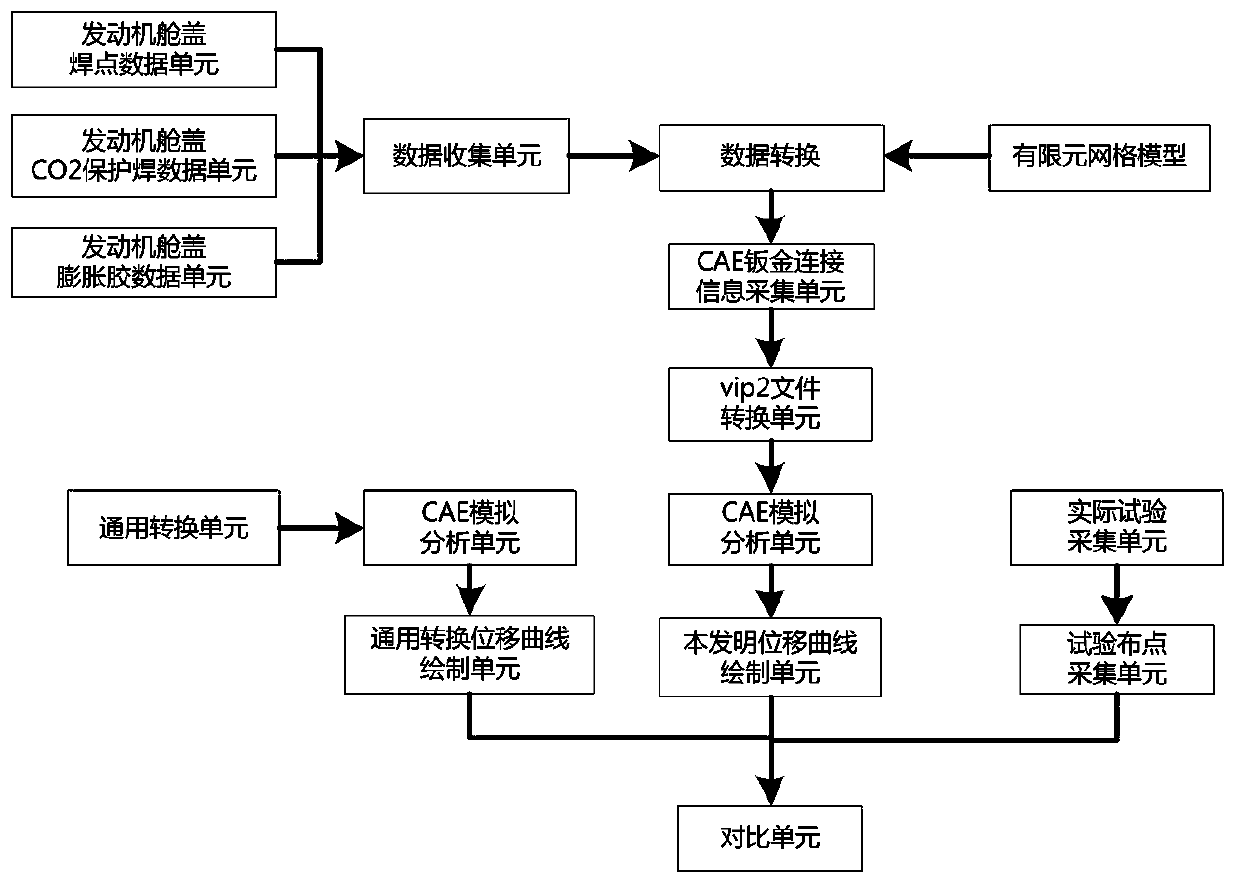

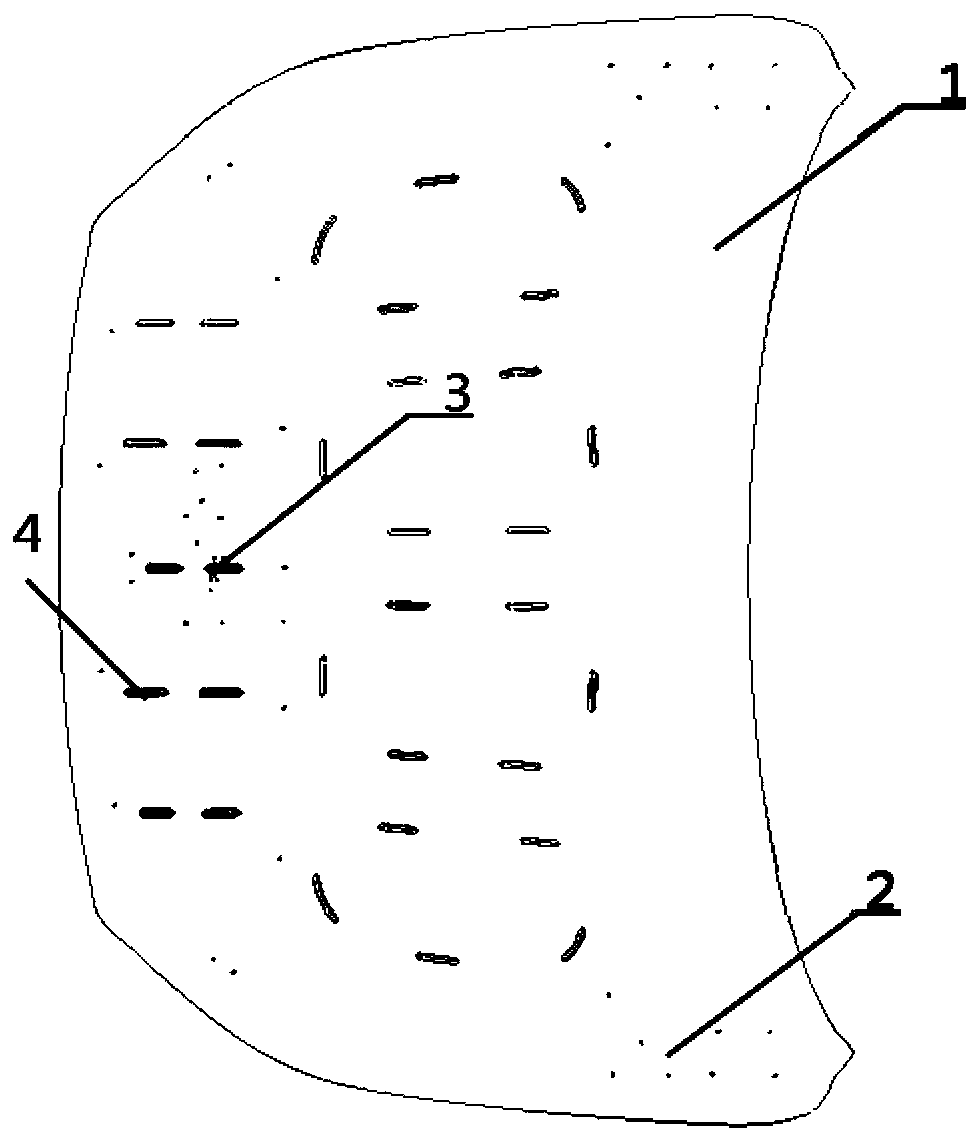

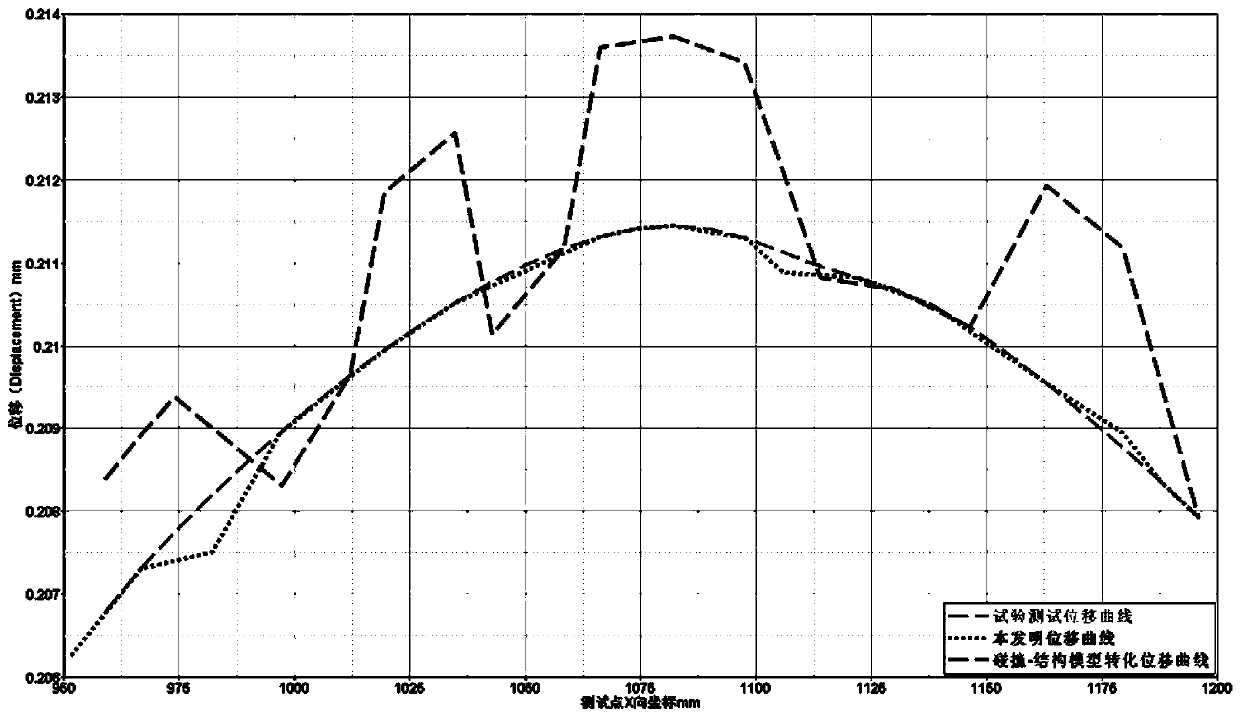

[0027] The following combination Figure 1~4 , describe the content of the present invention in detail through specific implementation methods:

[0028] figure 2 1 is the engine compartment cover, 2 is the welding spot of the engine compartment cover, and 3 is the CO of the engine compartment cover 2 Shielded welding, 4 is the engine compartment cover expansion glue.

[0029] Depend on figure 1 As shown, the figure includes: engine compartment cover welding point data unit, engine compartment cover CO 2 Protected welding data unit, engine compartment cover expansion glue data unit, actual test acquisition unit, general conversion unit, is characterized in that: described engine compartment cover welding spot data unit, engine compartment cover CO 2 The output terminals of the shielded welding data unit and the engine hatch expansion rubber data unit are connected to the input terminal of the data conversion unit through the data collection unit; the input terminal of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com