Method for remote control of material testing machine

A material testing machine and remote control technology, applied in the field of control, can solve the problems of cumbersome system wiring, high investment and maintenance costs, poor system scalability and mobile performance, etc., and achieve the effect of solving cumbersome wiring and reasonable methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

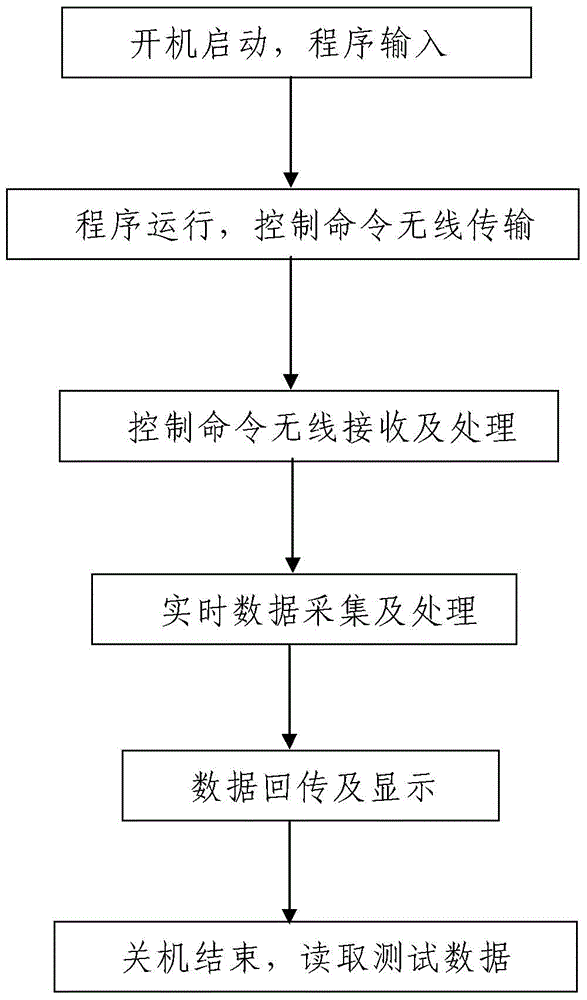

[0021] Such as figure 1 Shown, the present invention comprises the following steps:

[0022] Step 1, start up, program input: firstly fix the material to be tested on the material testing machine, secondly power on the material testing machine, and then press the start / pause button on the remote control, the material testing machine will follow the The system preset program starts to work; the material testing machine includes a base, a specimen fixture, a screw, a beam, a motor that drives the screw to move the beam up and down through a precision reducer, and is installed on the base The controller; the remote controller includes a housing, a circuit board contained in the housing, a program input button arranged on the housing, a motor speed adjustment knob, a start / pause button, a stop button, and an alarm indicator light and LCD display screen; if you need to work according to the artificially set program, you can press the start / pause button, the material testing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com