Copper alloy for electronic/electrical equipment, copper alloy thin sheet for electronic/electrical equipment, conductive component for electronic/electrical equipment, and terminal

An electronic, electrical and conductive element technology is applied in the fields of copper alloys for electronic and electrical equipment, copper alloy sheets for electronic and electrical equipment, conductive elements and terminals for electronic and electrical equipment, and can solve the problem of inability to improve shearing workability and shearing workability. Insufficient and deteriorating hot workability, etc., achieve the effect of sufficiently excellent stress relaxation resistance, reliable stress relaxation resistance, and excellent bending workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

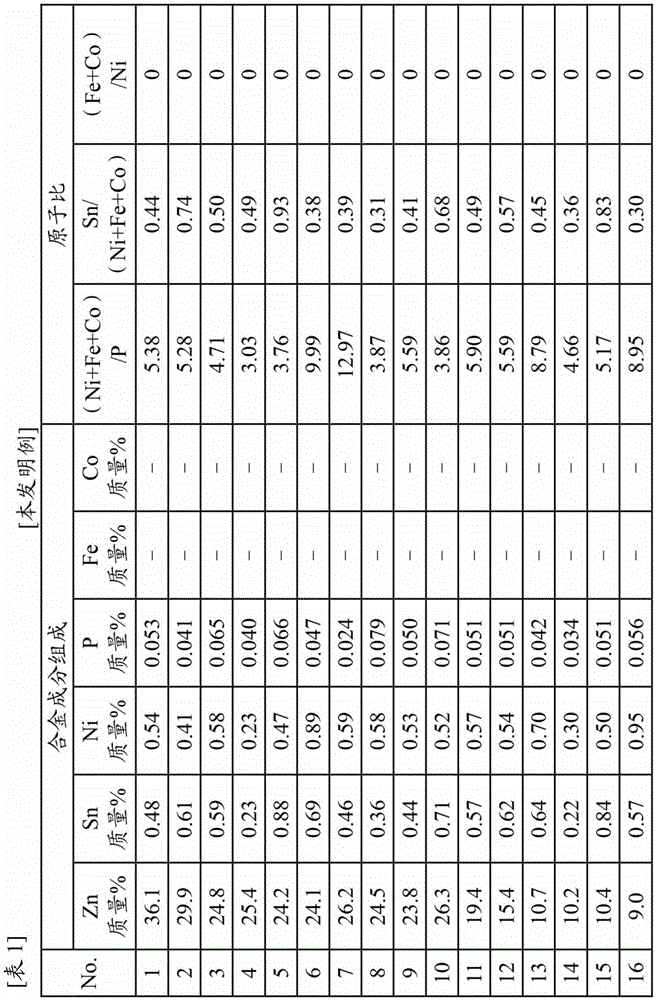

[0153] Hereinafter, the results of confirmatory experiments conducted to confirm the effects of the present invention are shown together with comparative examples as examples of the present invention. In addition, the following examples are used to illustrate the effects of the present invention, and the structures, processes, and conditions described in the examples do not limit the technical scope of the present invention.

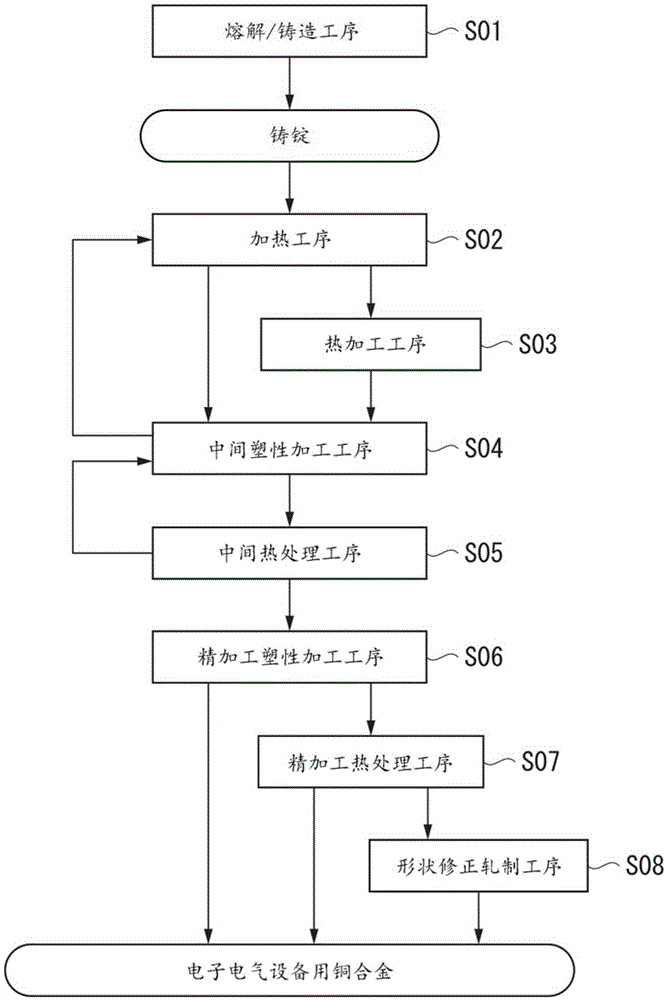

[0154] First, a raw material composed of a Cu-40% Zn master alloy and oxygen-free copper (ASTMB152C10100) with a purity of 99.99% by mass or higher was prepared, which was placed in a high-purity graphite crucible, and the 2 The gas atmosphere is melted using an electric furnace. Various additive elements were added to the copper alloy melt, the alloy melt having the composition shown in Tables 1 to 4 was melted, and poured into a mold to produce an ingot. In addition, the size of the ingot was about 30 mm in thickness×about 50 mm in width×about 200 mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com