Sealing structure of implanted type device and manufacturing method of sealing structure

A technology of sealing structure and manufacturing method, applied in the fields of implant stimulator, electrotherapy, medical science, etc., can solve problems such as aging, degradation, cracking, re-crosslinking, adverse biological reactions, and negative effects of implanted objects, and achieve Improved biosafety, long-term implant reliability, and improved airtight performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

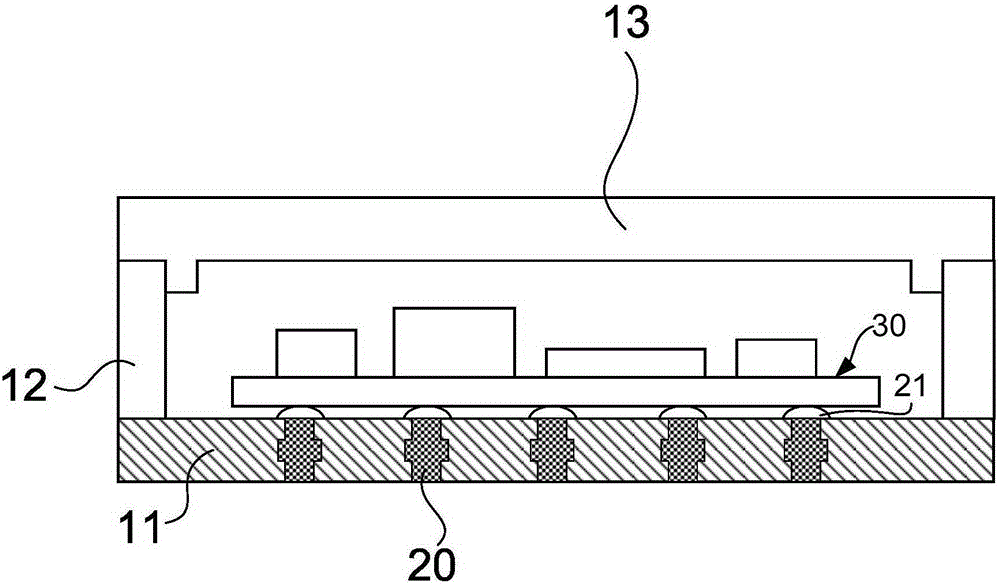

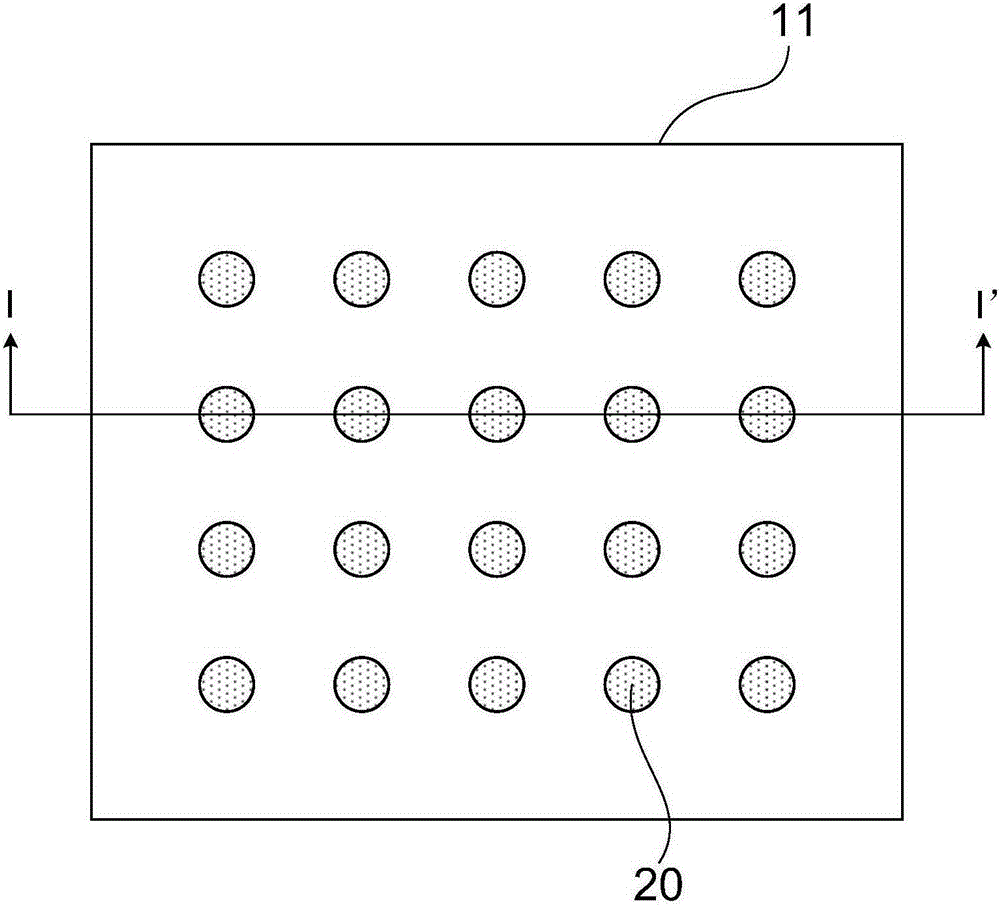

[0038] figure 1 A perspective structural view of the sealing structure 10 of the implantable device according to the first embodiment of the present invention is shown. figure 2 showfigure 1 The internal schematic diagram of the sealing structure 10 of the implantable device is shown.

[0039] Such as figure 1 with figure 2 As shown, the sealing structure 10 of the implantable device according to the first embodiment of the present invention includes a ceramic base 11 , a metal ring 12 and a metal cover 13 . Specifically, the sealing structure 10 is formed as a sealing body having an accommodating space for accommodating the electronic component 30 by disposing (for example, welding) a metal ring 12 and a metal cover 13 on the ceramic substrate 11 .

[0040] Additionally, if figure 1 As shown, the sealing structure 10 is substantially in the shape of a cuboid. In this embodiment, the size of the sealing structure 10 of a typical implantable device is, for example, 10 mm...

no. 2 approach

[0091] Below, refer to Figure 8 , the sealing structure 101 of the implantable device according to the second embodiment of the present invention will be described.

[0092] Figure 8 A schematic cross-sectional view of the ceramic substrate 111 of the sealing structure 101 of the implantable device according to the second embodiment of the present invention is shown. For convenience of description, the sealing structure 101 here only shows the parts different from the sealing structure 10 of the implantable device related to the first embodiment. Such as Figure 8 As shown, the ceramic substrate 111 of the sealing structure 101 of the implantable device according to the second embodiment of the present invention is different from the ceramic substrate 11 of the sealing structure 10 of the implantable device according to the first embodiment of the present invention The point is that the metal post 201 in the ceramic substrate 111 is composed of a post body 201a and two po...

no. 3 approach

[0099] Below, refer to Figure 9 , the sealing structure 102 of the implantable device according to the third embodiment of the present invention will be described.

[0100] Figure 9 A schematic cross-sectional view of the ceramic substrate 112 of the sealing structure 102 of the implantable device according to the third embodiment of the present invention is shown. For convenience of description, the sealing structure 102 here only shows the parts different from the sealing structure 10 of the implantable device related to the first embodiment. Such as Figure 9 As shown, the ceramic substrate 112 of the sealing structure 102 of the implantable device according to the third embodiment of the present invention is different from the ceramic substrate 11 of the sealing structure 10 of the implantable device according to the first embodiment of the present invention The point is that the metal post 202 in the ceramic substrate 112 is composed of a post body 202a and a threade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com