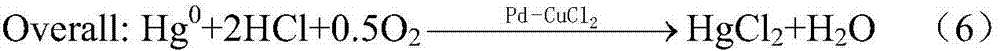

pd‑cucl 2 /γ‑al 2 o 3 Preparation method and application of mercury removal composite catalyst

A composite catalyst, pd-cucl2 technology, applied in chemical instruments and methods, separation methods, dispersed particle separation and other directions, can solve the problems of poor sulfur resistance, smelting flue gas mercury removal process, etc., achieve excellent sulfur resistance, preparation technology Simple, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 0.6696g copper chloride CuCl 2 2H 2 O and 0.0957g dichlorotetramine palladium Pd (NH 3 ) 4 Cl 2 , respectively dissolved in 25mL of deionized water to make an impregnation solution; using γ-Al with a diameter of 1.5-2mm 2 o 3 The ball is used as the catalyst carrier, and the equal volume impregnation method is used to weigh 2g of γ-Al 2 o 3 Immerse in 3mL of the above palladium-containing impregnation solution; immerse in ultrasonic for 10min, air-dry for 6h and then dry at 60°C for 2h; then take 2.3mL of the above-mentioned cupric chloride solution and impregnate it into the above catalyst, immerse in ultrasonic for 10min, air-dry for 6h and then dry at 60°C After drying for 2 hours, the obtained catalyst was activated in an air atmosphere at a temperature of 200-400°C for 6 hours (1h at 200°C, 1h at 300°C, 4h at 400°C), and the catalyst Pd(0.4%)-CuCl 2 (3.1%) / γ-Al 2 o 3 (baking).

Embodiment 2

[0036] Take 2.1739g copper chloride CuCl 2 2H 2 O and 0.3107g dichlorotetramine palladium Pd (NH 3 ) 4 Cl 2 , respectively dissolved in 25mL of deionized water to make an impregnation solution; using γ-Al with a diameter of 1.5-2mm 2 o 3 The ball is used as the catalyst carrier, and the equal volume impregnation method is used to weigh 2g of γ-Al 2 o 3 Immerse in 3mL of the above palladium-containing impregnation solution; immerse in ultrasonic for 10min, air-dry for 6h and then dry at 60°C for 2h; then take 2.3mL of the above-mentioned cupric chloride solution and impregnate it into the above catalyst, immerse in ultrasonic for 10min, air-dry for 6h and then dry at 60°C After drying for 2 hours, the obtained catalyst was activated in an air atmosphere at a temperature of 200-400°C for 6 hours (1h at 200°C, 1h at 300°C, 4h at 400°C), and the catalyst Pd(1.4%)-CuCl 2 (10%) / γ-Al 2 o 3 (baking).

Embodiment 3

[0038] Take 0.6696g copper chloride CuCl 2 2H 2 O and 0.00479g dichlorotetramine palladium Pd (NH 3 ) 4 Cl 2 , respectively dissolved in 25mL of deionized water to make an impregnation solution; using γ-Al with a diameter of 1.5-2mm 2 o 3 The ball is used as the catalyst carrier, and the equal volume impregnation method is used to weigh 2g of γ-Al 2 o 3 Immerse in 3mL of the above palladium-containing impregnation solution; immerse in ultrasonic for 10min, air-dry for 6h and then dry at 60°C for 2h; then take 2.3mL of the above-mentioned cupric chloride solution and impregnate it into the above catalyst, immerse in ultrasonic for 10min, air-dry for 6h and then dry at 60°C After drying for 2 hours, the obtained catalyst was activated in an air atmosphere at a temperature of 200-400°C for 6 hours (1h at 200°C, 1h at 300°C, 4h at 400°C), and the catalyst Pd(0.2%)-CuCl 2 (3.1%) / γ-Al 2 o 3 (baking).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com