Casting mould structure capable of pulling core firstly and then ejecting

A core-pulling and mold-first technology, applied in the field of core-pulling and then ejecting the mold structure, can solve the problems of increasing product stress, increasing core rod wear, increasing demolding force, etc., reducing production costs, reducing friction, reducing effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

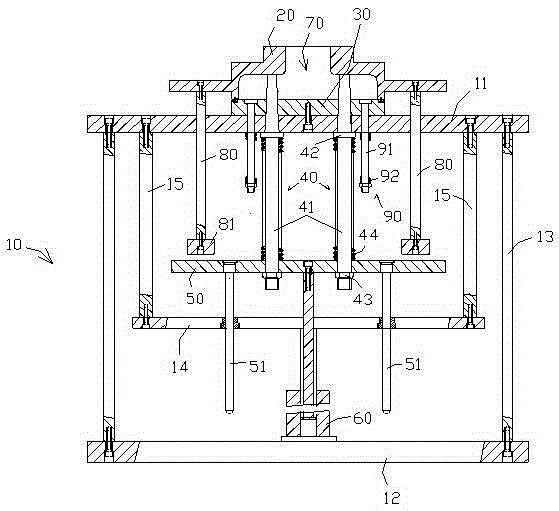

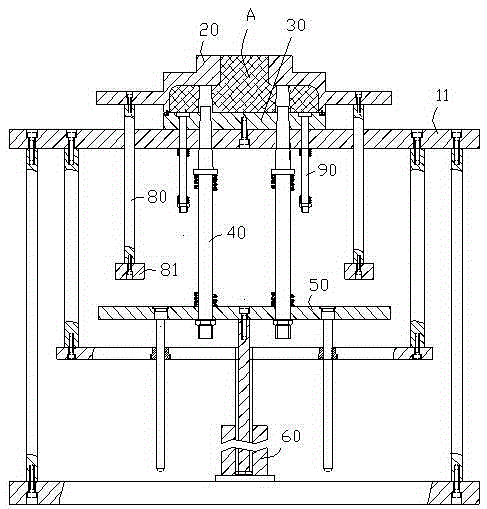

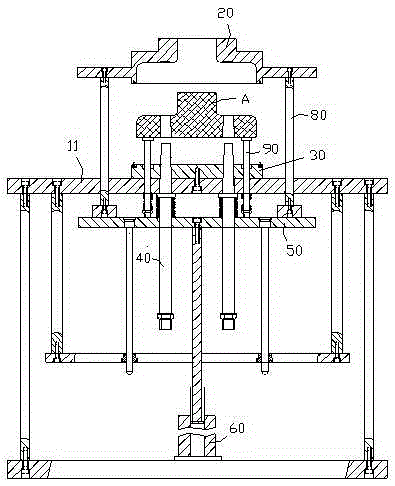

[0022] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0023] Such as figure 1 , 2 As shown in and 3, the mold structure includes a frame 10 and a movable mold 20, a fixed mold 30, a movable mandrel 40, a top plate 50 and a hydraulic cylinder 60 arranged on the frame.

[0024] Described frame 10 comprises the work platform 11 of top, the base plate 12 of below and the connecting rod 13 that is used to connect described work platform 11 and base plate 12, and described work platform 11 is used for supporting fixed mold 30, and described base plate 12 is used for In order to support the hydraulic cylinder 60, the working platform 11 is also connected with a guide support plate 14 through a vertical strut 15, the guide support plate 14 cooperates with the guide post 51 through a guide sleeve, and the guide post 51 is fixedly connected with the top plate 50, so The top plate improves the stability o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com