Design method of built-in baffle for directional solidification vane gating system

A technology of directional solidification and pouring system, applied in the field of precision casting, can solve problems such as delaying the development of blades, and achieve the effect of shortening the trial production cycle, ensuring quality, and saving trial production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The ProCAST software used in the embodiment of the present invention was purchased from USE Company of the United States.

[0032] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0033] The design method of the built-in baffle for the directional solidification blade gating system of this embodiment is carried out according to the following steps:

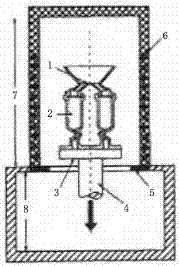

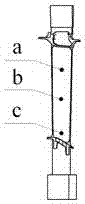

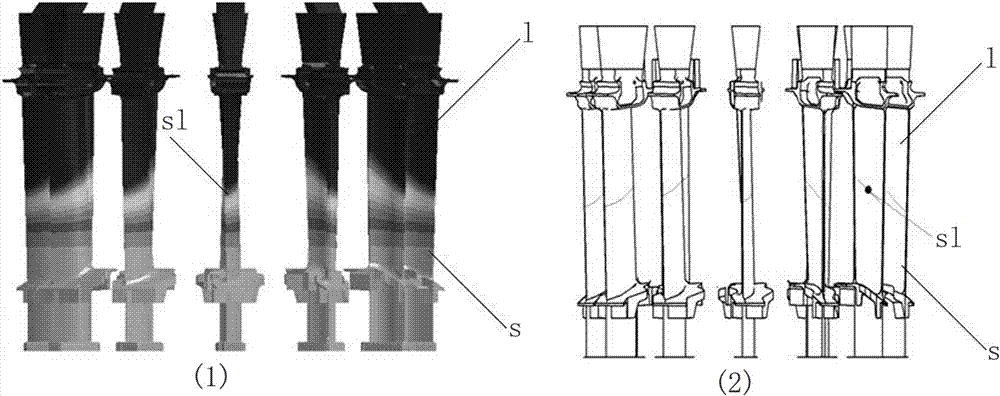

[0034] (1) Assemble the directional solidification vane pouring system without built-in baffles, assemble the sprue cup, upper disc, center column tube, chassis and ceramic vane shells together, the ceramic vane shells are arranged in a ring, and the adjacent vanes The minimum interval is 25mm, the thickness of the single shell is 6~10mm, the initial section is designed as a cuboid with a height of 15~25mm, the top riser is designed as a disc shape, and the thickness is 15~20mm. Blocking without feeding, placed on the water-cooled copper plate of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com