A kind of inorganic micro-irrigation tube and used mold and method for manufacturing micro-irrigation tube with the mold

A technology of micro-irrigation and mould, which is applied to botany equipment and methods, moulds, manufacturing tools, etc. It can solve problems such as high cost, high pressure, and large wetting angle, and achieve the effect of low price and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The micro-irrigation pipe product of embodiment 1 has a large water permeability and is suitable for plants with high water demand. However, because the pipe wall is thin, the bulk density is small, and the strength is low, in order to shorten the production cycle, the value of L is the best with 2000mm.

Embodiment 2

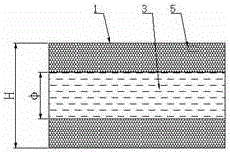

[0062] Example 2 φ=16mm, H=40mm, L=3000mm, bulk density=400±20kg / m 3

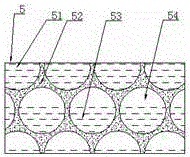

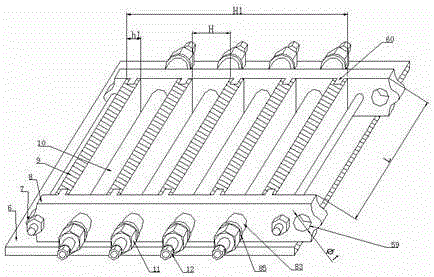

[0063] 1. If image 3 , where φ=16mm, H=40mm, L=3000mm, bulk density=400±20kg / m 3 . Lift the micro-irrigation pipe mold and fasten the screw 7, apply a release agent on the part of the micro-irrigation pipe mold that may contact the foam concrete slurry, first put on the mold pipe 10 and position the nut 11 at one end, and then tighten the other end The nut of the mold pipe 10 is straightened;

[0064] 2. Use high-quality foam concrete foaming agent, use a foaming machine to make foam with a foam diameter of 0.08-0.12mm, and use ordinary Portland cement, 1% polypropylene fiber by mass, and 60% water to make concrete slurry , and mix the foam with concrete slurry to make a dry bulk density of 400±20kg / m 3 foam slurry, and then pour it into the micro-irrigation pipe mold;

[0065] 3. Scraping, under the condition of 20°C, after 6 hours, after the initial setting of the foam concrete slurry, remove the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com