Composite-wing aircraft with tail rotor

A composite and aircraft technology, applied in the field of aircraft, can solve the problems of inconvenient ultra-low speed or hovering flight, difficulty in short-distance take-off and landing, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

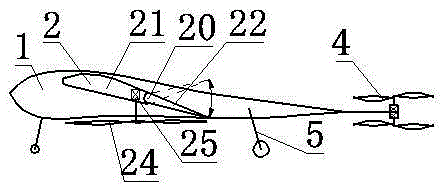

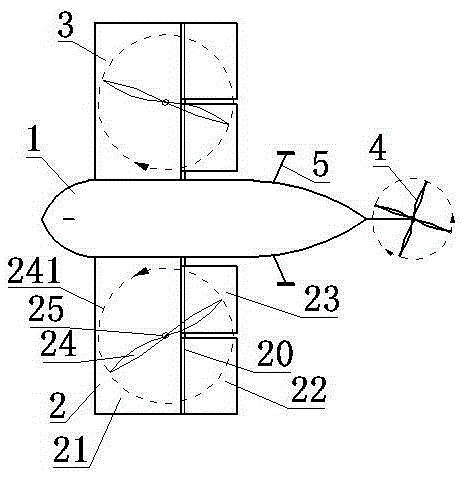

[0009] Now in conjunction with accompanying drawing, the present invention is described in detail: a kind of composite wing aircraft with tail rotor, comprises fuselage 1, left composite wing 2, right composite wing 3, coaxial double-rotor tail rotor 4 and landing gear 5 . The fuselage 1 is equipped with a control system and airborne equipment. The left compound wing 2 and the right compound wing 3 have the same structure, and they are symmetrically installed on the left and right sides of the fuselage 1. The coaxial dual-rotor tail rotor 4 is located at the tail of the fuselage 1. The coaxial dual-rotor tail rotor 4 includes two electric propellers with the same parameters and opposite directions. Online, they are controlled independently. Landing gear 5 adopts wheel structure. The concrete structure of left compound wing 2 is: left compound wing 2 comprises wing shaft 20, front wing 21, rear outer wing 22, rear inner wing 23, rotor 24 and engine 25. Engine 25 provides po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com