Adjustable filtration type oil separating tank device for separating oil-water mixture

A technology of oil-water mixture and oil-water separation, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as automatic adjustment of grease traps, field limitations, etc., to achieve Good oil discharge effect, reduced sediment deposition, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention are described in detail as follows:

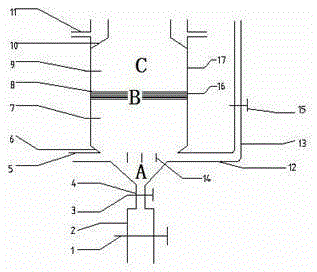

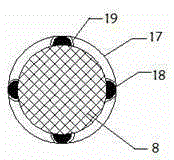

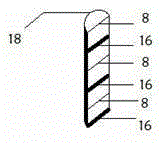

[0026] In this example, see Figures 1 to 4 , an adjustable filter oil separator device for oil-water mixture separation, including a vertical straight oil-water separation box shell 17, an oil-water separation membrane 8 set in the oil-water separation box, a sewage inlet 12, a drain port 5, and an oil drain Port 11, sediment discharge port, in the oil-water separation box, the area where the oil-water separation membrane 8 is located is the filter area B, the upper part of the filter area B is the oil slick area C, the lower part of the filter area B is the buffer sedimentation area A, and the sewage inlet The pipeline 12 is connected with the sewage conveying pipe 13 provided with the main valve 15. The oil-water separation membrane 8 is height-adjusted according to the proportion of oil and water in the sewage, so as to adjust the space size of the oil slick zone C. The oil-water se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com