A kind of preparation method of high coercivity fe-pt alloy

A high coercive force, alloy technology, applied in the field of preparation of high coercive force Fe-Pt alloy, can solve the problem of less magnetic materials and achieve the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

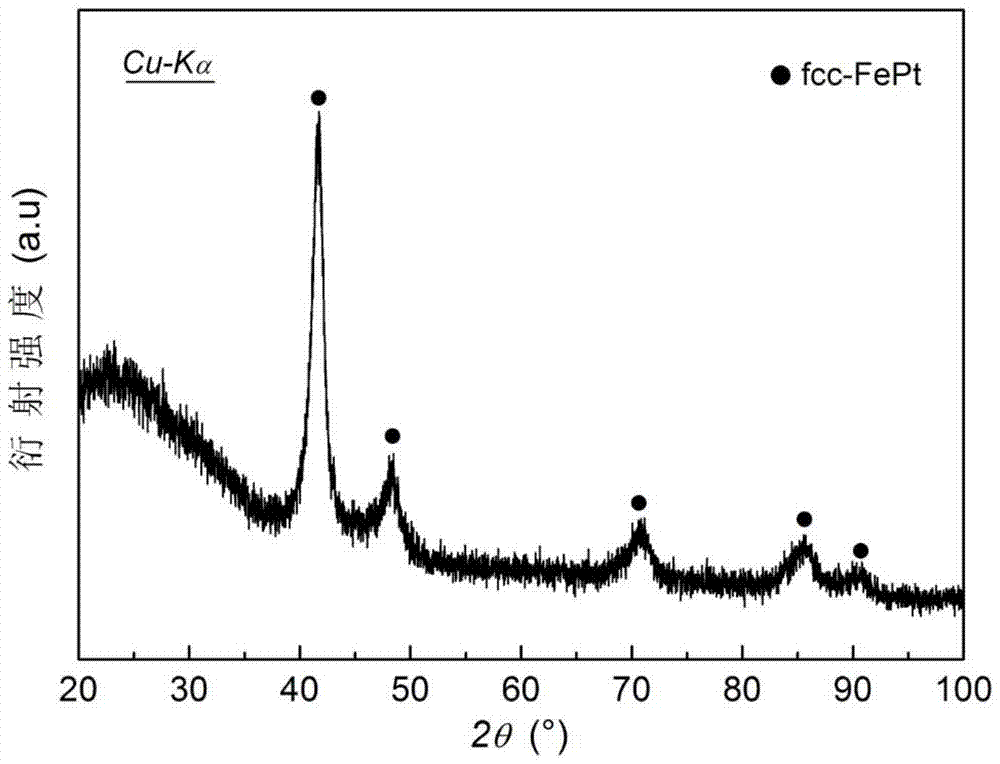

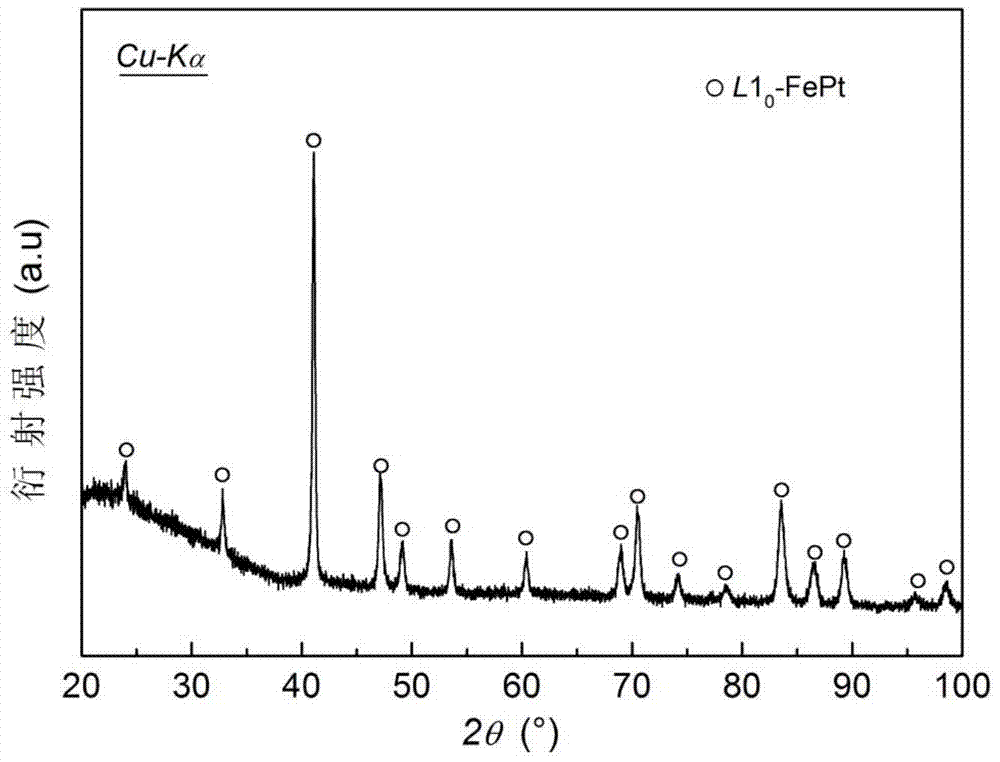

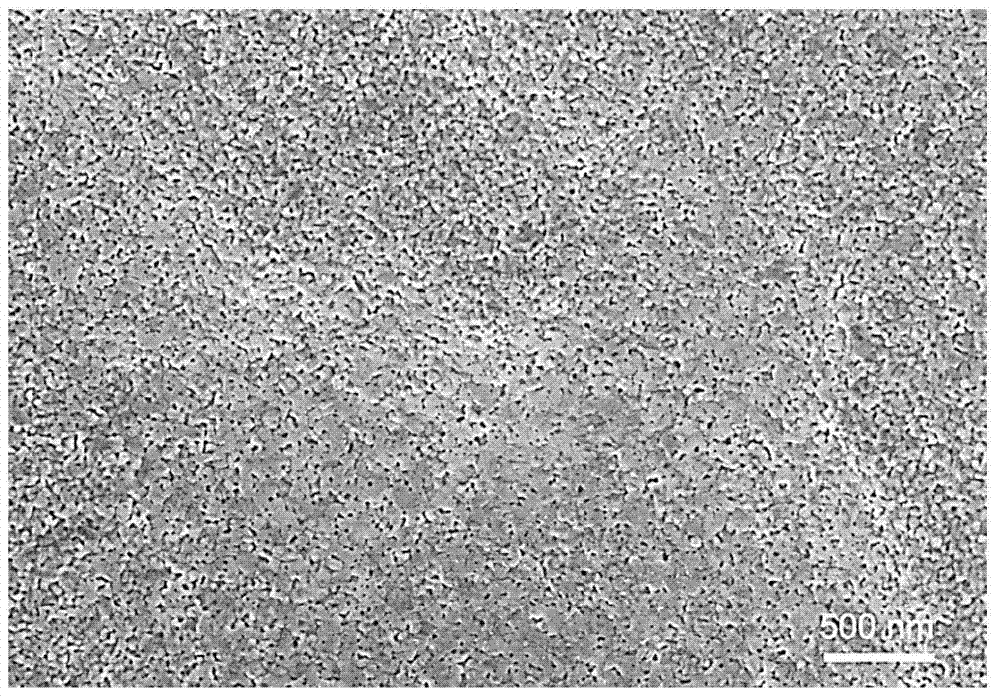

[0020] Embodiment 1: Now take composition as Fe 60 Pt 20 B 20 Taking the quenched alloy strip as an example, the implementation of the preparation and performance testing of the permanent magnetic Fe-Pt alloy will be described in detail in conjunction with the accompanying drawings.

[0021] The first step is to prepare the precursor alloy strip:

[0022] 1.1 Select high-purity Fe (99.9wt.%), Pt (99.95wt.%) and B (99.5wt.%) raw materials according to Fe 60 Pt 20 B 20 (atomic percent) ingredients are weighed for batching.

[0023] 1.2 Alloy ingot melting

[0024] Mix the weighed metal raw materials into the water-cooled copper crucible of the arc melting furnace, and evacuate to 6×10 -3 Pa, and then filled with an appropriate amount of argon to start melting the alloy. After melting, the alloy ingot was turned upside down and smelted repeatedly 4 times to obtain Fe with uniform composition. 60 Pt 20 B 20 alloy ingot.

[0025] 1.3 Preparation of quenched strip samples...

Embodiment 2

[0041] Embodiment 2: the precursor alloy is Fe 65 Pt 15 B 20 quench strip

[0042] The specific implementation steps are the same as in Example 1, the corrosion solution in the second step 2.2 dealloying treatment is a sulfuric acid solution with a concentration of 0.1mol / L, the constant potential voltage is -120mV, and the annealing temperature in the third step 3.1 is 670°C. The time is 900s, the linear speed of the roller surface is 35m / s in the process of single-roller stripping, and the final obtained alloy i h c , M s and M r They are: 7.69kOe, 46.05emu / g and 33.63emu / g.

Embodiment 3

[0043] Embodiment 3: the precursor alloy is Fe 65 Pt 20 B 15 quench strip

[0044] The specific implementation steps are the same as in Example 1, the corrosion solution in the second step 2.2 dealloying treatment is a sulfuric acid solution with a concentration of 0.01mol / L, the constant potential voltage is -110mV, and the annealing temperature in the third step 3.1 is 670°C. The time is 600s, the linear speed of the roller surface is 40m / s in the process of single-roller stripping, and the final alloy obtained i h c , M s and M r They are: 7.48kOe, 48.28emu / g and 35.63emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com