Compound silicate board with fireproof function

A composite silicate and functional technology, which is applied in the direction of fire prevention, hydraulic material layered products, building components, etc., can solve the problems of minimizing hazards, not being able to effectively prevent fires, etc., and avoid unnecessary losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

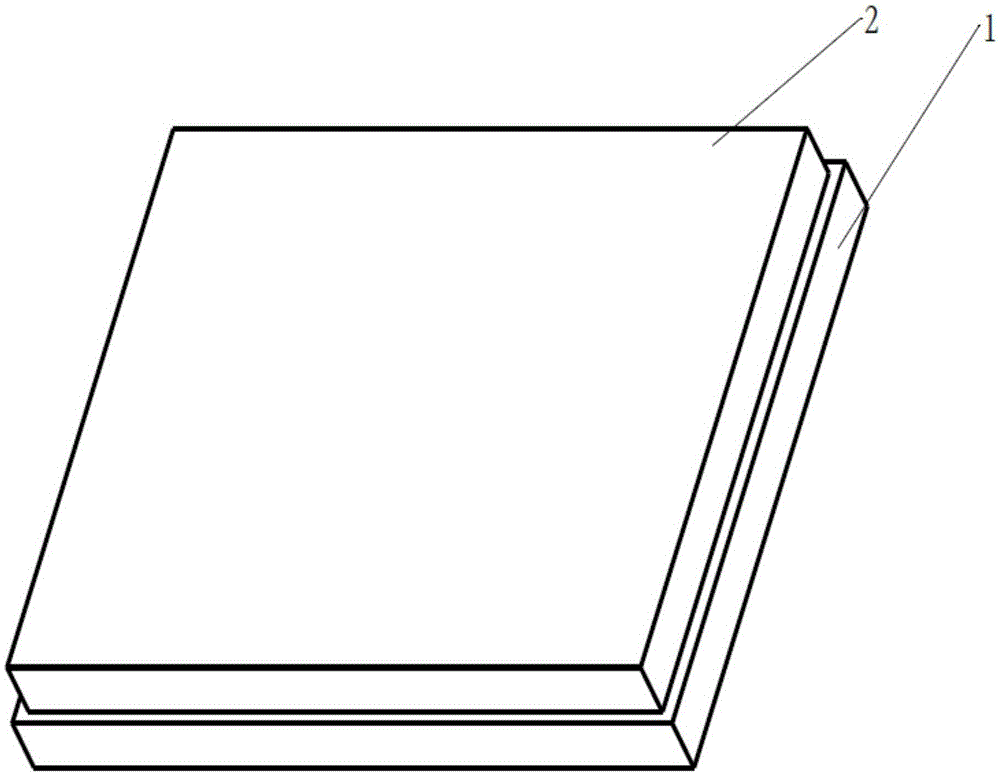

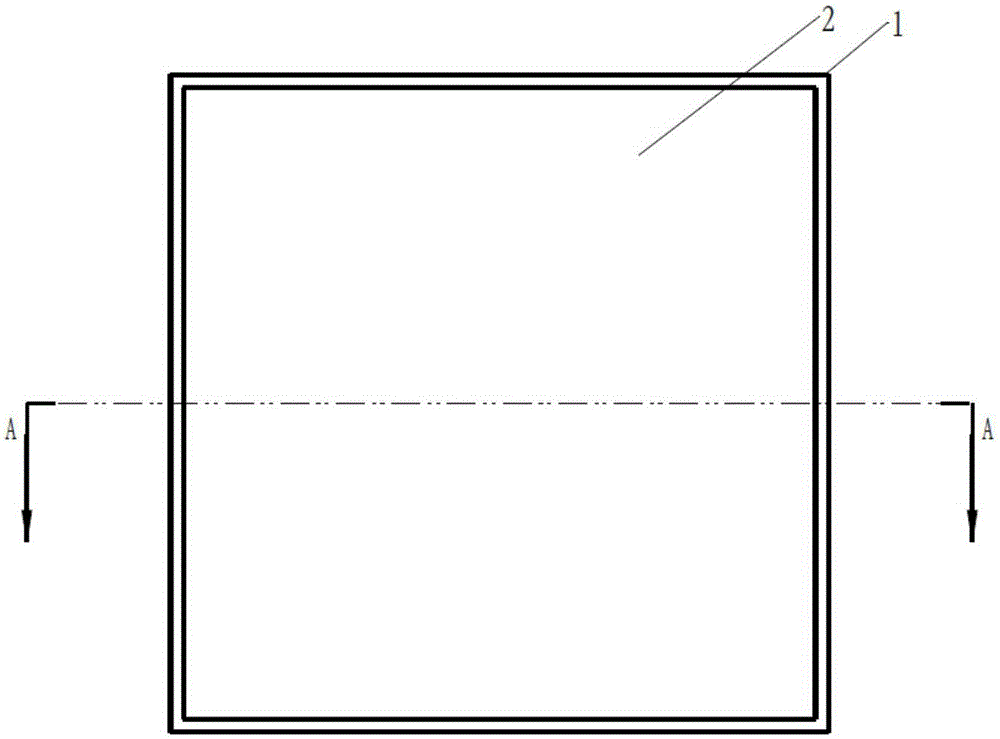

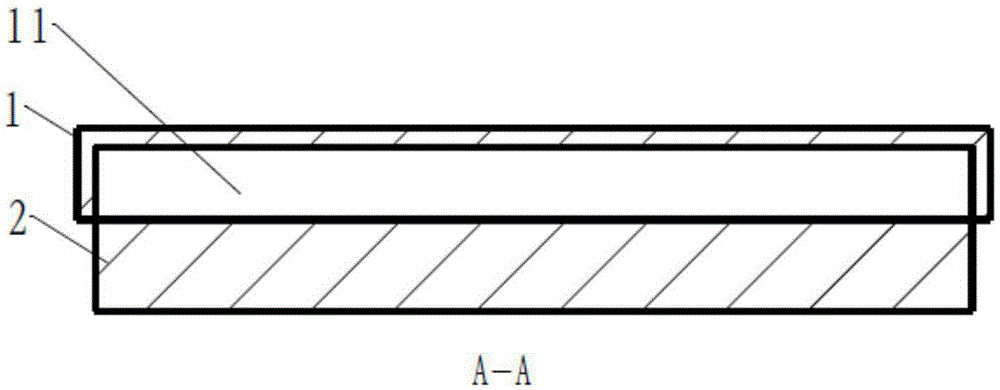

[0019] Such as figure 1 , 2 , 3 and 4, a composite silicate board with fireproof function, the silicate board includes a first ply 1 and a second ply 2, between the first ply 1 and the second ply 2 Adhesives are coated between the contact surfaces, and the adhesives can be any one or more than two of polyethylene, polypropylene, and polyurethane. Of course, it is not limited to these materials, and other coatings with the same function can also meet this demand. , the thickness of the glue coating can be 1.5mm or 2mm, of course, it can also be any value in the middle of the two; a pit 11 is dug inside the first plate layer 1; the shape of the pit 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com