Fireproof coating for wooden furniture and preparation method thereof

A technology for fire-retardant coatings and wooden furniture, applied in fire-resistant coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of low fire resistance and corrosion resistance, and achieve high fire and corrosion resistance and drying speed. Fast, erosion-blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

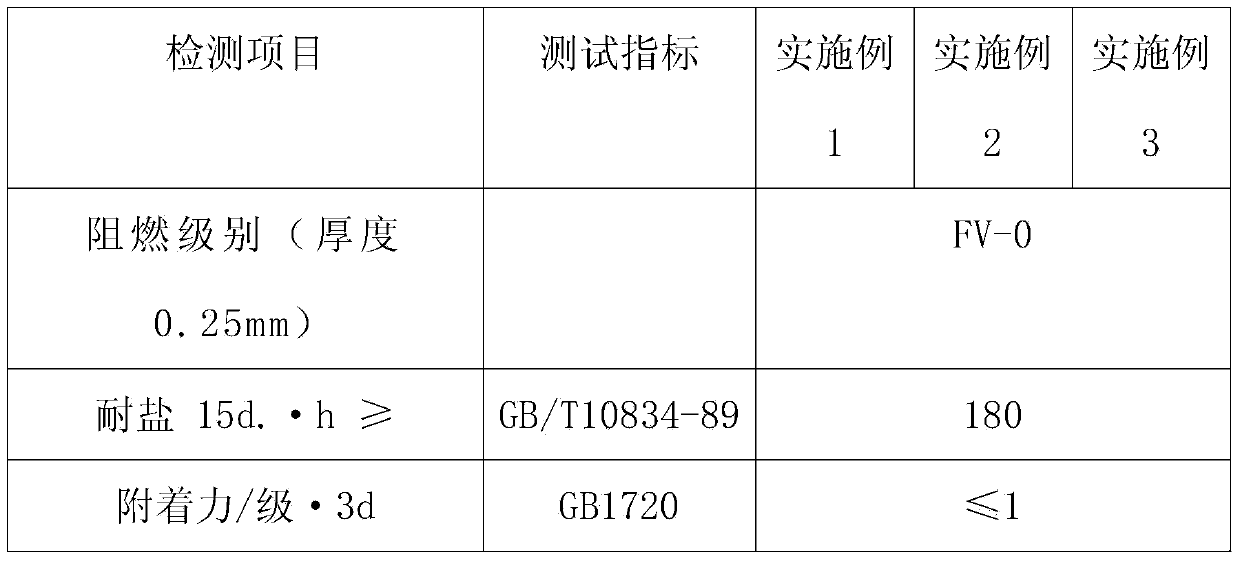

Examples

Embodiment 1

[0010] This embodiment provides a fireproof coating for wooden furniture, which contains the following components in parts by mass: 30 parts of water, 0.3 parts of sodium dodecylbenzenesulfonate, 90 parts of ammonium polyphosphate, diethylene glycol methyl ethyl ether acetic acid 1 part of ester, 1 part of melamine formaldehyde resin, 10 parts of phosphorus tripolyoxide, 8 parts of chlorohydrin, 2.8 parts of chlorinated paraffin, 1.5 parts of dioctyl phthalate, 2 parts of sodium fluorosilicate, 0.15 parts of turpentine, 4 parts of cobalt naphthenate, 5 parts of silica.

[0011] The preparation steps of a kind of fireproof coating for wooden furniture are as follows: first mix phosphorus oxide tripolyoxyethanol and chlorohydrin, reflux in a water bath with a temperature of 60°C for 2h, then distill at 65°C for 0.5h, and then add one-third Parts by mass of water, distilled at 65°C for 2 hours to obtain a flame retardant; then mix ammonium polyphosphate, diethylene glycol methyl ...

Embodiment 2

[0013] This embodiment provides a fireproof coating for wooden furniture, which contains the following components in parts by mass: 42 parts of water, 1 part of sodium dodecylbenzenesulfonate, 110 parts of ammonium polyphosphate, diethylene glycol methyl ethyl ether acetic acid 4 parts of ester, 4.8 parts of melamine formaldehyde resin, 22 parts of phosphorus tripolyoxide, 16 parts of chloroethanol, 6 parts of chlorinated paraffin, 2.9 parts of dioctyl phthalate, 5 parts of sodium fluorosilicate, 0.25 parts of turpentine, 10 parts of cobalt naphthenate, 12 parts of silica.

[0014] The preparation steps of a kind of fireproof coating for wooden furniture are as follows: first mix phosphorus oxide tripolyoxyethanol and chlorohydrin, reflux in a water bath with a temperature of 70°C for 2h, then distill at 65°C for 0.5h, and then add one-third Parts by mass of water, distilled at 65°C for 2 hours to obtain a flame retardant; then mix ammonium polyphosphate, diethylene glycol met...

Embodiment 3

[0016] This embodiment provides a fireproof coating for wooden furniture, which contains the following components in parts by mass: 36 parts of water, 0.65 parts of sodium dodecylbenzenesulfonate, 100 parts of ammonium polyphosphate, diethylene glycol methyl ethyl ether acetic acid 2.5 parts of ester, 3 parts of melamine formaldehyde resin, 16 parts of phosphorus oxide, 12 parts of chloroethanol, 4.4 parts of chlorinated paraffin, 2.2 parts of dioctyl phthalate, 3.5 parts of sodium fluorosilicate, 0.2 parts of turpentine, 7 parts of cobalt naphthenate, 8 parts of silica.

[0017] The preparation steps of a kind of fireproof coating for wooden furniture are as follows: first mix phosphorus oxide tripolyoxyethanol and chlorohydrin, reflux in a water bath with a temperature of 65°C for 2h, then distill at 65°C for 0.5h, and then add one-third Parts by mass of water, distilled at 65°C for 2 hours to obtain a flame retardant; then mix ammonium polyphosphate, diethylene glycol methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com