Self-suction type novel liquid sulfur pump

A liquid sulfur pump and self-priming technology, applied in the field of new self-priming liquid sulfur pumps, can solve the problems of large vibration and swing of the pump shaft, medium corrosion, inconvenient maintenance, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

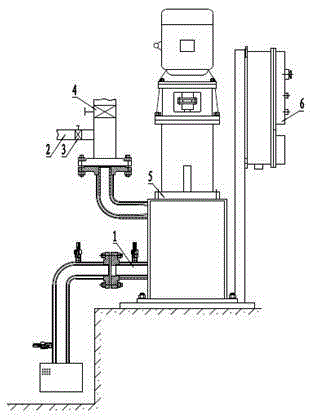

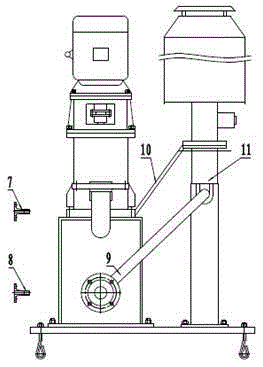

[0017] Depend on Figure 1-2 It can be seen that the present invention is composed of four parts: a delivery pump, a self-priming device, a heat tracing device, and a return line. Vacuum device 11, control box 6, inlet suction pipe 9 and top suction pipe 10, wherein one end of inlet suction pipe 9 is connected to vacuum device 11 and the other end is connected to inlet pipe 1, and one end of top suction pipe 10 is connected to vacuum device 11 and the other end is connected to conveying The top of the pump chamber. The control box 6 controls the automatic start and stop of the vacuum device 11 and the delivery pump. The whole equipment is equipped with steam inlet 7 and steam outlet 8, and the heating steam is provided by the external heating pipe network. All pipelines and joints are equipped with jacket heat tracing pipes, and the pump cover and pump body are equipped with heat tracing chambers. And steam is passed through the heating cavity, the steam enters from the stea...

Embodiment 2

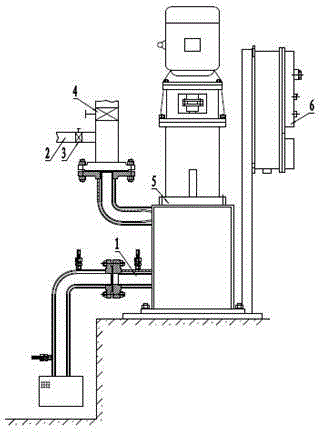

[0019] Depend on Figure 3-4 It can be seen that Embodiment 2 is basically the same as Embodiment 1, the difference being that the vacuuming device adopts a top vacuuming method to vacuumize the delivery pump, and the vacuuming device 11 is connected with the outlet pipe 12 of the delivery pump 5 through the top suction pipe 10 Vacuum.

Embodiment 3

[0021] Depend on Figure 5 It can be seen that Embodiment 3 is basically the same as Embodiment 1, the difference being that the vacuuming device adopts a top vacuuming method to vacuumize the delivery pump, and the vacuuming device 11 is connected to the top of the volute of the delivery pump 5 through the top suction pipe 10 Vacuum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com