Preparation method for Raman enhancement substrate

A substrate and Raman technology, applied in the field of material chemistry technology and detection and analysis, can solve the problems of high cost, poor repeatability of nanoparticle self-assembly length, and difficult preparation, and achieve easy control, good Raman enhancement performance, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

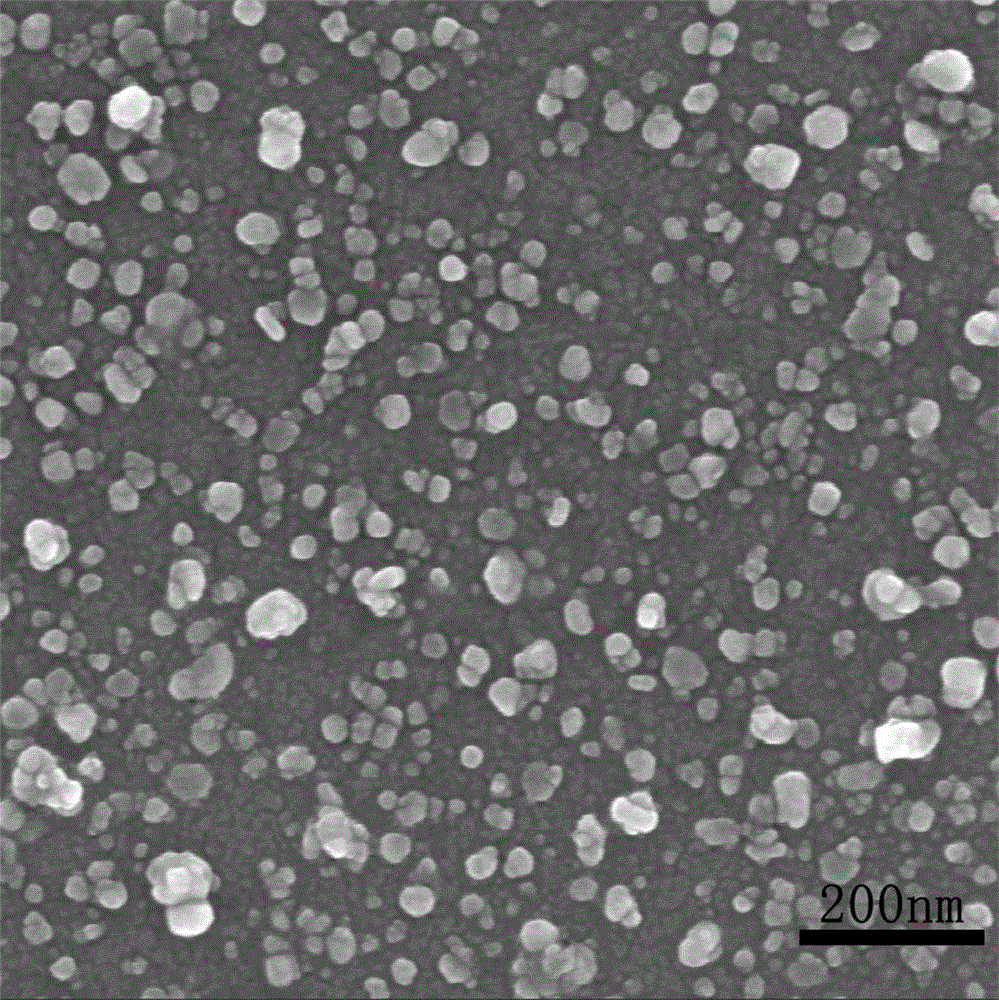

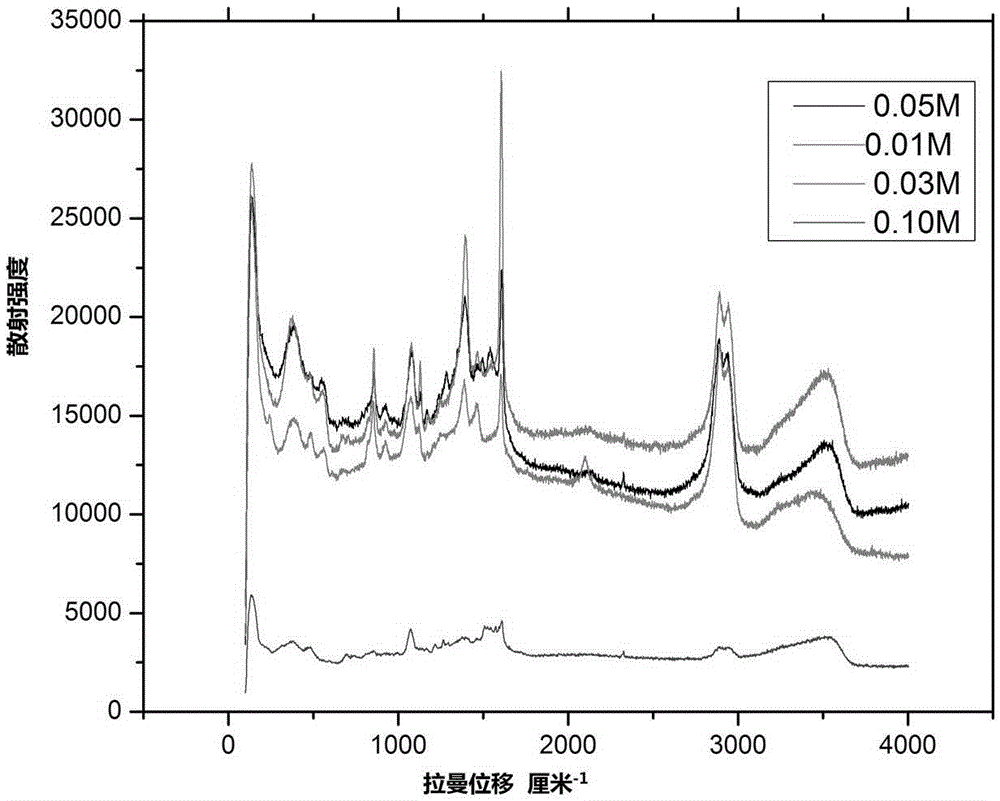

[0019] Use magnetron sputtering to prepare a 50nm thick zinc nano film on a glass substrate, configure a mixed solution of 0.01M silver nitrate and 0.005MCTAB, put the prepared nano zinc base into the prepared mixed solution for 60s, take it out, and wash it with alcohol and deionized water 10 times. figure 1 SEM image of the prepared substrate.

Embodiment 2

[0021] Use magnetron sputtering to prepare a 100nm thick zinc nano film on a glass substrate, configure a mixed solution of 0.03M silver nitrate and 0.015MCTAB, put the prepared nano zinc base into the prepared mixed solution for 30s, take it out, and wash it with alcohol and deionized water 10 times.

Embodiment 3

[0023] Use magnetron sputtering to prepare 80nm thick zinc nano film on the glass substrate, prepare a mixed solution of 0.05M silver nitrate and 0.025MCTAB, put the prepared nano zinc base into the prepared mixed solution for 20s, take it out, and wash it with alcohol and deionized water 10 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com