Device and method for controlling auto-calibration process of pulse signal generator

A pulse signal, automatic calibration technology, applied in the field of electrical measurement, can solve the problem that the automatic calibration process cannot be fully controlled, and achieve the effect of improving the overall control level and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

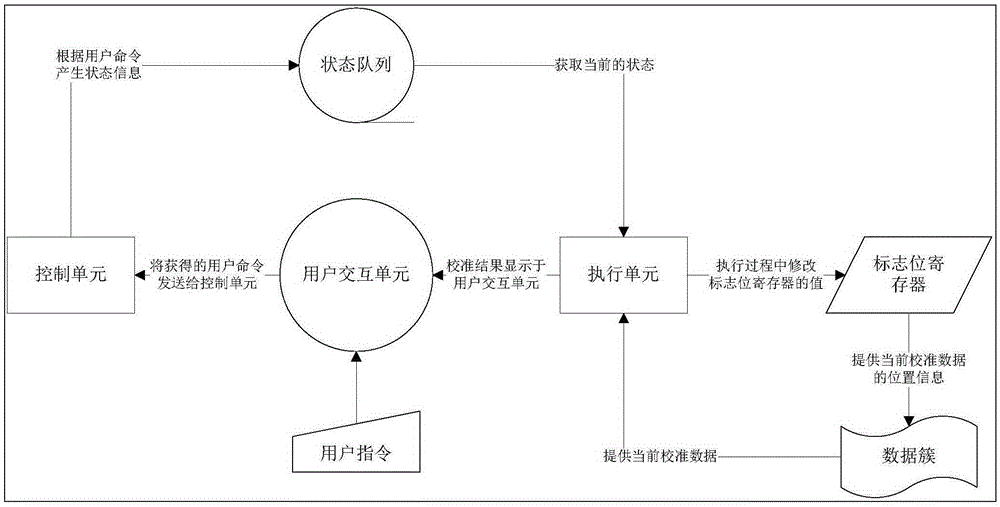

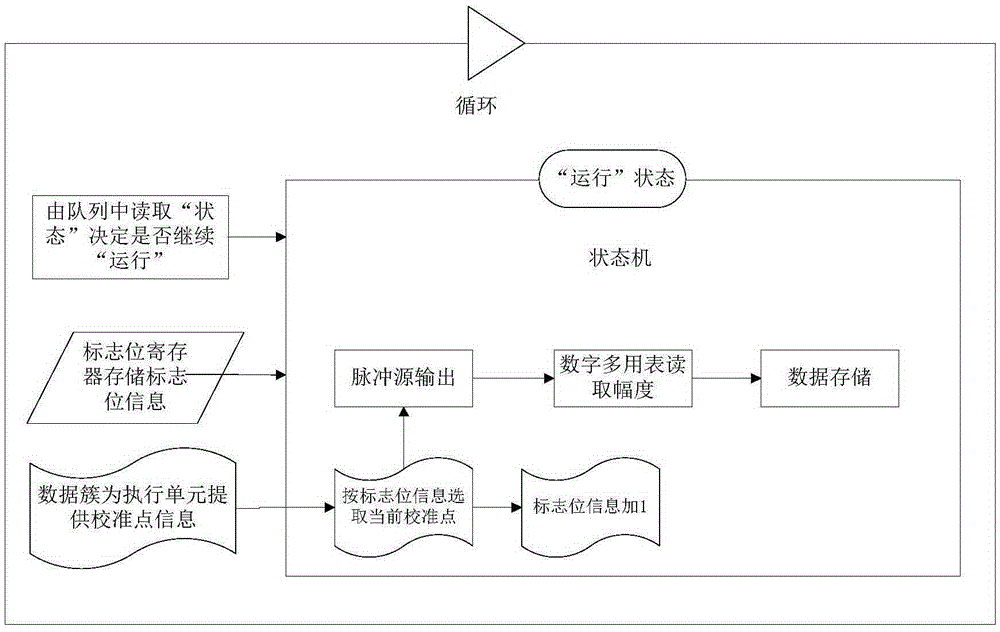

[0039] The present invention designs a control module based on the state machine of LabVIEW, the producer-consumer cycle structure and the queue, and controls the automatic calibration of each parameter in the pulse signal generator. Such as figure 1 The schematic diagram of the control module structure is shown. The module is composed of three main parts: the user account transfer unit, the control unit and the execution unit; the user interaction unit is the main user interface, which is used to respond to user instructions and display calibration data to the user. The control unit Generate state information to control the execution of the calibration process according to the user instruction received by the interaction unit; the execution unit is used to run the calibration process according to the control command and generate a calibration result. The control unit, as a producer loop, sends status information (run, pause, stop or exit) into the status queue according to th...

Embodiment 2

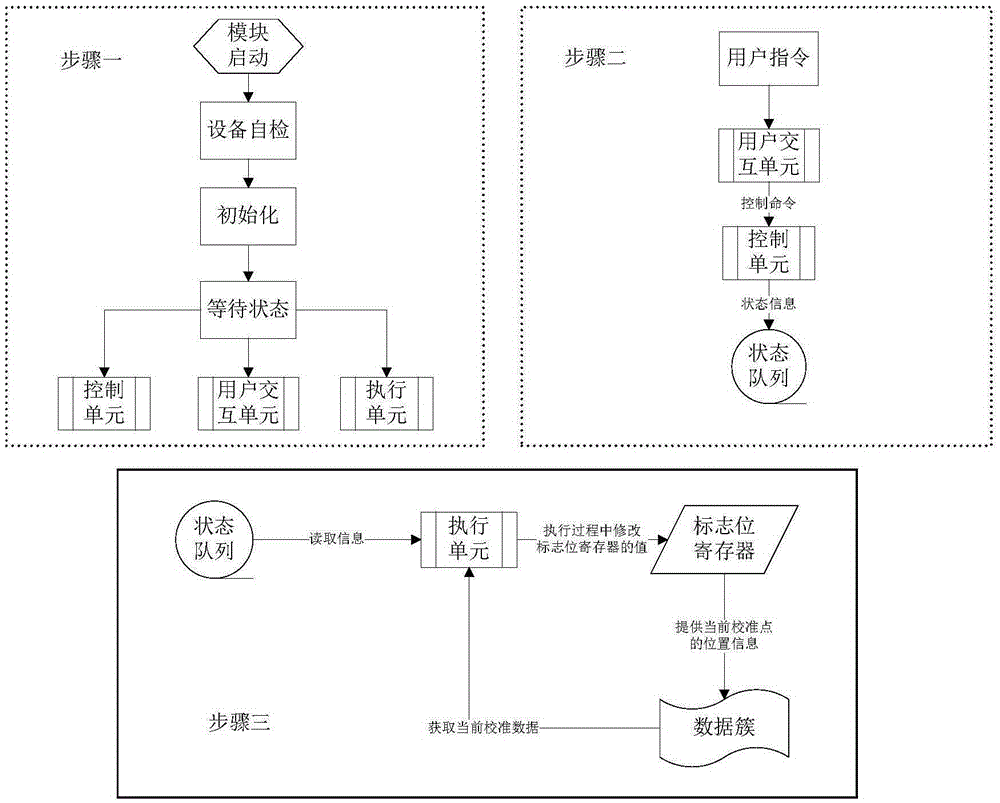

[0048] Such as figure 2 Shown is a schematic flow chart of the automatic calibration process control method of the automatic calibration process control module of the pulse signal generator proposed by the present invention. The control method based on the control module of the present invention will be described below by taking the pulse amplitude calibration as an example, specifically including the following process :

[0049] Step 1, after the automatic calibration process control module based on the pulse signal generator is started, first perform self-test and initialization, and write the calibration point of the pulse amplitude into the data cluster during initialization, and leave it to be called by the execution unit; at the same time, when it is initialized state, the control unit will send an initialization command to the execution unit through the state queue, so that it enters the waiting state, and then enters the waiting state itself, waiting for the user to g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com