A Simulation Method of Liquid Column Separation-Bridging Water Hammer Based on 3D CFD

A liquid column separation and simulation method technology, applied in the field of hydraulic numerical simulation of hydropower stations, can solve the problems of difficult simulation of one-dimensional models, complex hydraulic transition process, inability to effectively simulate the shape and position of holes, etc. Effectiveness of efficient, simplified solution methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment, further illustrate the present invention, should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various equivalent forms of the present invention All modifications fall within the scope defined by the appended claims of the present application.

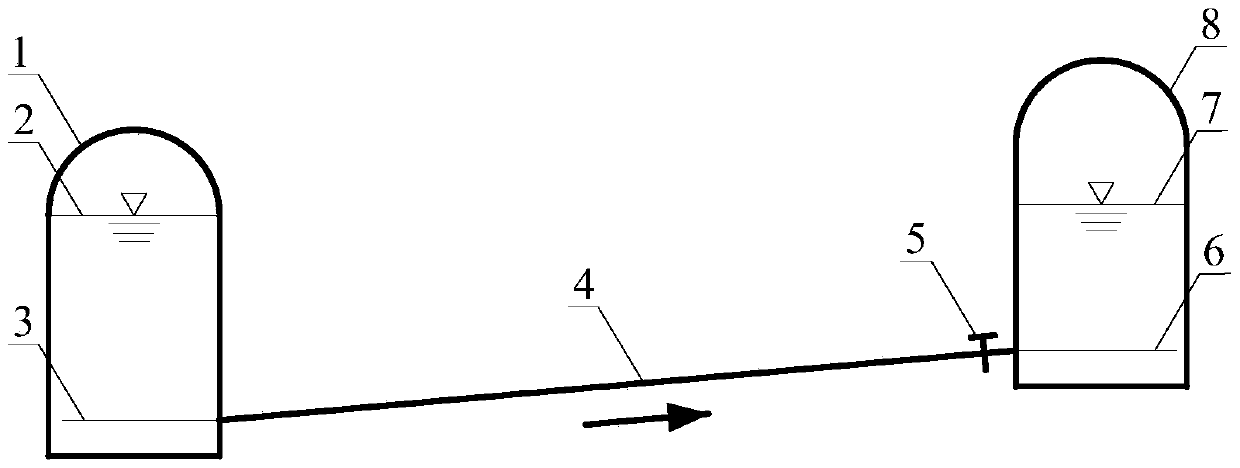

[0037] Embodiment: in order to verify and analyze the simulated effect of the CFD-based liquid column separation-bridging water hammer simulation method provided by the present invention, the liquid column separation-bridging water hammer experimental device system designed and built by Simpson in 1986 is used to verify this The effectiveness of the inventive method, its simplified schematic diagram of the experimental device is shown in figure 1 . The system consists of upstream pressure water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com