Inner water-cooled generator stator anti-vapor blocking device and method

A generator stator, water cooling technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., to achieve the effect of improving reliability and preventing overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

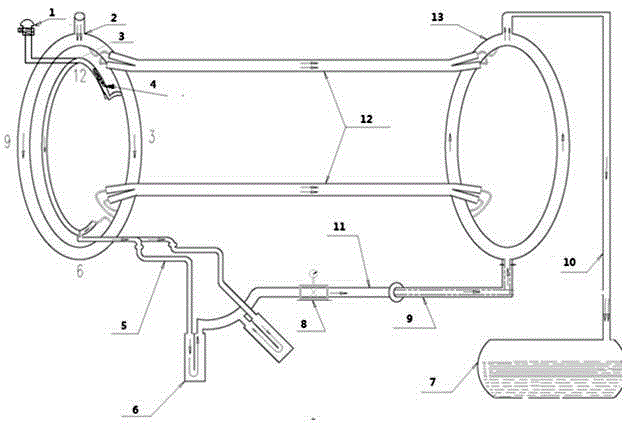

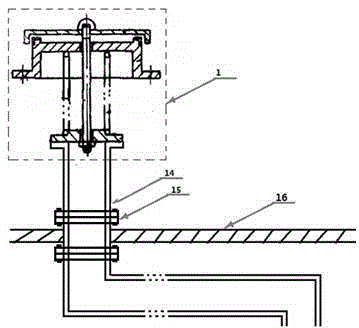

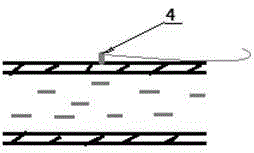

[0036] Such as figure 1 , 3 , shown in 4; a water internally cooled generator stator anti-steam blocking device, which is connected to the stator waterway on the generator cooling system; the stator waterway includes: connected to the excitation terminal confluence pipe 2 of the water inlet, respectively connected to the excitation terminal The wire rod 12 at the water outlet end of the confluence pipe 2 and the parallel connection ring 3 are connected to the small confluence pipe 11 through the transition lead wire 5 and the porcelain sleeve 6, and the steam end confluence pipe 13 is respectively connected to the water discharge end of the wire rod 12 and the water outlet end of the small confluence pipe 11, and the steam end confluence The pipe 13 is connected to the cold water tank 7 through the return pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com