Coaxial spiral re-entry pulse forming line

A helical and coaxial technology, applied in the field of coaxial helical reentrant pulse forming lines, can solve the problems of difficult realization and complex structure, and achieve the effect of simple structure, easy realization and small waveform distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

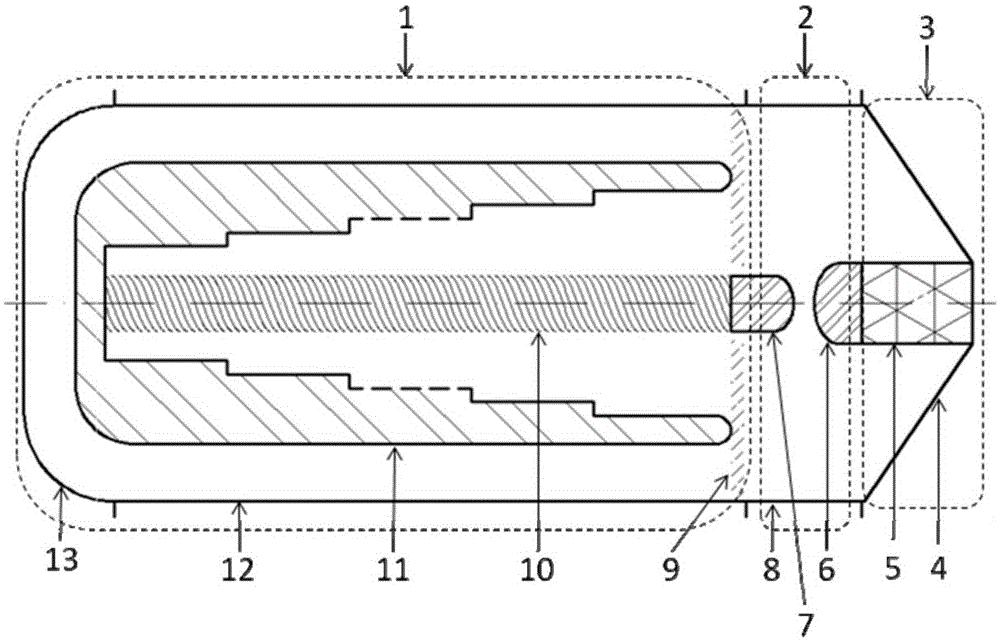

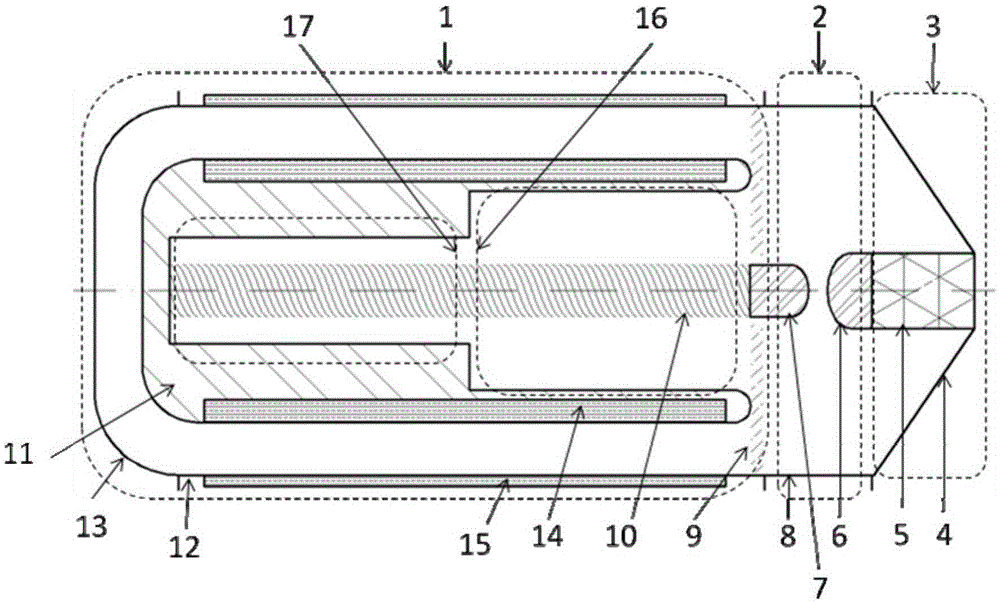

[0025] The coaxial spiral reentrant pulse forming line structure includes three parts: the reentrant forming line section 1 , the main switch section 2 and the load section 3 . The reentrant forming line segment 1 is composed of forming line outer cylinder 12, middle cylinder 11, spiral inner cylinder 10, rear end cover 13 and insulating filling medium. The spiral inner cylinder 10 has a uniform caliber, adopts thin-diameter wires to be helically wound with multiple starting ends, adjacent wires are insulated, and the winding pitch is uniform. The outer surface of the middle cylinder 11 is a straight cylinder, and the inner surface is a stepped cylinder with different calibers. The three conductor cylinders, the wire outer cylinder 12, the middle cylinder 11, and the spiral inner cylinder 10, are approximately equal in length and gradually decreasing in diameter, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com