Process of marking a textile substrate

A textile and substrate technology, applied in the field of dyeing compositions, can solve problems such as indistinguishability, and achieve the effect of sensitive verification methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Use CO containing 2 (120 ℃, 250bar), 1-2% disperse dyes (20mg / kg textile) and the supercritical dyeing medium of the Fe(II)-maltol that weight is about 1% of disperse dyes weight is to polyester fabric (polyester fabric) Ethylene terephthalate, polyethyleneterephtalate) for dyeing.

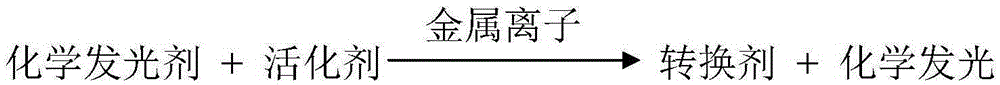

[0101] After dyeing, a piece of dyed fabric was sprayed with a previously prepared alkaline solution prepared by mixing 1.2 g of luminol, 6 g of NaOH and 150 g of water. Next, add 3-4 drops of hydrogen peroxide solution (3%) dropwise to the alkaline sprayed part.

[0102] The chemiluminescent reaction occurs when acetone is added to the part of the textile product that has been sprayed with an alkaline solution and an oxidizing agent. The chemiluminescent reaction produces a few seconds of blue light.

Embodiment 2

[0104] Textile products are treated in the same manner as in Example 1, except that iron pentacarbonyl (Fe(CO) 5 ) instead of Fe(II)-maltol.

[0105] Likewise, when acetone was added, blue chemiluminescence was observed.

Embodiment 3

[0107] Use CO containing 2 (120 ℃, 250bar), 1-2% disperse dyes (20mg / kg textile) and the supercritical dyeing medium of 8-hydroxyquinoline that weight is about 1% of disperse dyes weight to polyester fabric (polyphenylene Ethylene diformate) for dyeing.

[0108] After dyeing, a piece of dyed fabric was sprayed with a test solution containing the composition shown in Table 1.

[0109] Table 1

[0110]

[0111] A chemiluminescent reaction was observed when acetone was added to the part of the textile product that had been sprayed with the test liquid. The chemiluminescent reaction produces an intense blue light that lasts for a few seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com