Rhinestone inspection equipment

A technology for inspecting equipment and rhinestones, applied to measuring devices, material analysis through optical means, instruments, etc., can solve problems such as low production efficiency, many false and missed inspections, and high labor intensity, so as to improve production efficiency and ensure The effect of processing quality and reducing manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

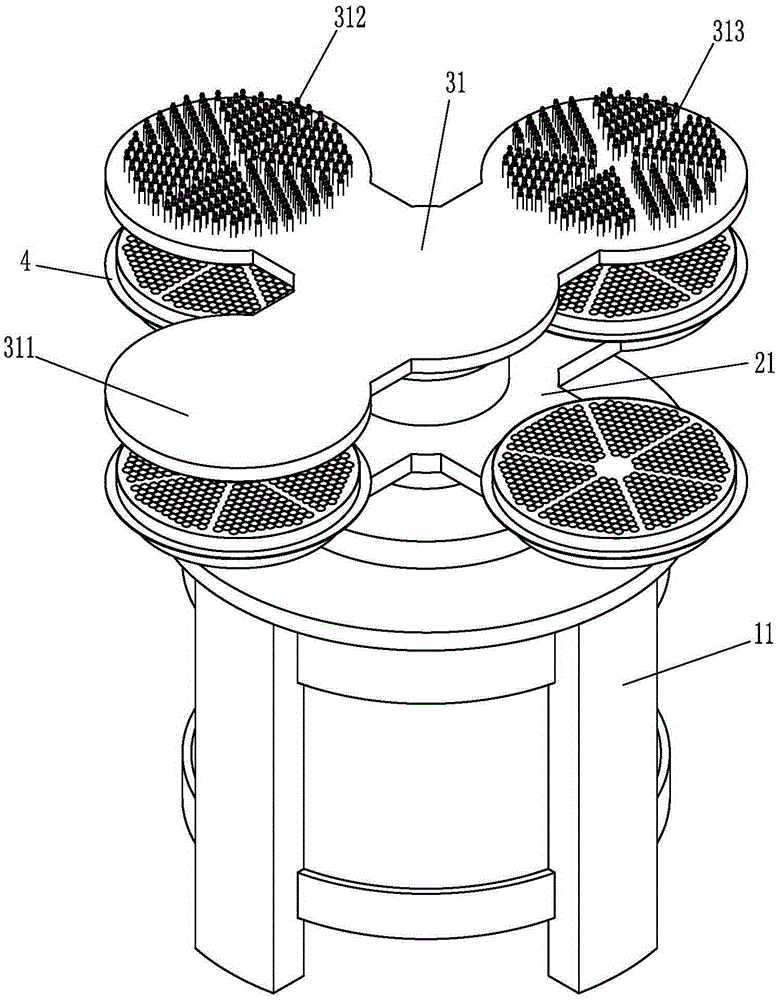

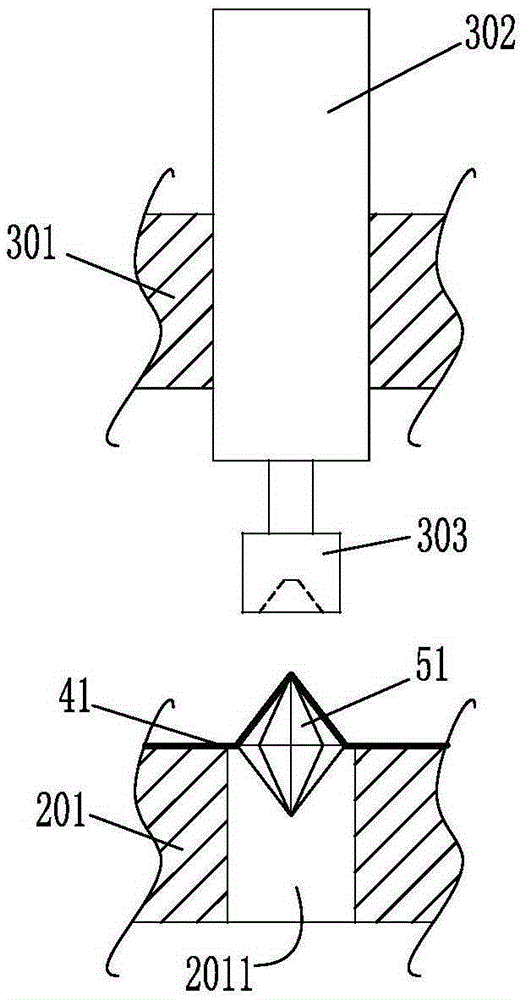

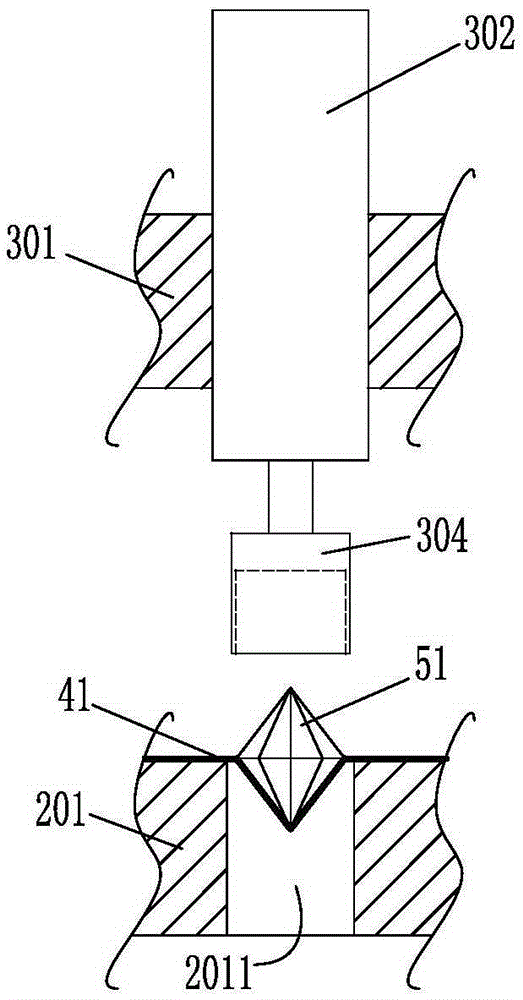

[0169] Such as figure 1 The shown a kind of rhinestone inspection equipment comprises frame 11, and frame 11 is provided with a rotating frame 21, and rotating frame 21 is driven to rotate by its driving mechanism, is provided with a disassembly station, an inspection station around rotating frame 21 311 and two rejecting stations 312, 313, four tooling discs 201 for fixing the blister tray 4 are fixed on the rotating frame 21, and these tooling discs 201 are respectively connected with the disassembling station, the inspection station and the rejecting station. One-to-one corresponding setting, the tooling tray 201 is provided with a concave hole for accommodating the water drill on the blister tray 4; wherein, the inspection station 311 is provided with a detection device, and the detection device is on the tooling tray on the inspection station. The rhinestones on the blister tray are visually inspected to find out the defective rhinestones that need to be removed, and obta...

Embodiment 2

[0179] Such as Figure 8 , Figure 9 The shown rhinestone inspection equipment includes a frame 12. A fixed bracket 122 is arranged on the frame 12. A detection device and four rejecting devices are arranged on the fixed bracket 122. A tooling plate is arranged below the detecting device and the rejecting device. The tooling plate is driven by its driving mechanism to rotate horizontally. The tooling plate is provided with a concave hole for accommodating the rhinestones on the blister plate. The tooling plate is divided into multiple work station areas centered on the rotating axis of the tooling plate. One inspection area 322 , the four rejecting areas 323, 324, 325, 326 respectively reject the rhinestone blanks at different positions, and each detecting device and rejecting device are set up and down corresponding to a station area of the tooling tray; wherein, the detecting device is located at The rhinestones on the blister tray in the workstation area below it are vis...

Embodiment 3

[0182] A kind of rhinestone inspection method that the rhinestone inspection equipment of above-mentioned embodiment 1 and embodiment 2 adopts, comprises the following steps:

[0183] 1) Blister: Arrange multiple rhinestones to be inspected in the same direction and form them into a blister tray through blister molding. There are multiple adsorption holes formed on one surface of the blister tray, and the face or bottom of the rhinestone to be inspected is embedded in the adsorption holes. and fixed;

[0184] 2) Installation; fix the blister tray on the tooling tray, and the tooling tray is provided with a concave hole for accommodating the rhinestones to be inspected on the blister tray;

[0185] 3) Inspection; the detection device performs visual inspection on the uninspected rhinestones on the blister tray, finds out the rhinestones that have defects and needs to be removed, and obtains the relative position information of these rhinestones that need to be removed on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com