Method for eliminating flow field vortexes in tubular electrode electrolytic machining interval

A technology of machining gap and internal flow field, applied in electric machining equipment, electrochemical machining equipment, machining electrodes, etc., can solve the problems of affecting machining accuracy, deteriorating machining environment, reducing the stability of machining process, etc., and reducing short circuit in machining process. , the effect of improving process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

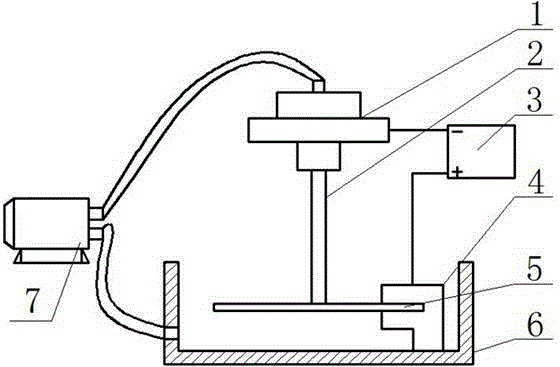

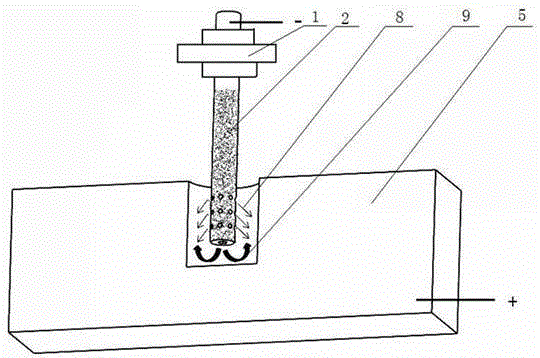

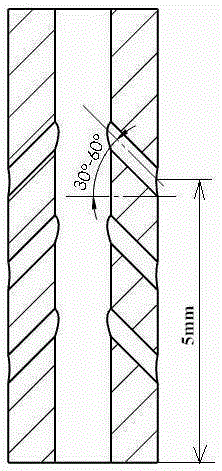

[0016] Such as figure 1 The schematic diagram of the setup for electrolytic machining of tube electrodes and figure 2 The schematic diagram of the processing area of the tube electrode electrolytic machining is shown, which includes: the clamping and sealing device 1 of the electrolytic machining machine tool, which is responsible for clamping the tube electrode and sealing the electrolyte; Connect the clamping and sealing device 1 of the electrolytic machining machine tool, and connect the negative pole of the processing power supply as the cathode of the electrolytic machining, and spray the electrolyte downward during processing; the processing power supply 3 provides the required DC power during processing; the workpiece fixture 4 is responsible for clamping and fixing The workpiece; the workpiece 5 is connected to the positive electrode of the processing power supply 3 as the anode of the electrolytic processing; the electrolytic cell 6 provides the electrolyte proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com