A high-precision rotatable electric spark perforator

A technology of electric spark and punching machine, which is applied in the field of mechanical processing, can solve the problems of inability to process parts, large size, and human injury, and achieve the effects of easy installation and transportation, reduced size, and avoid bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

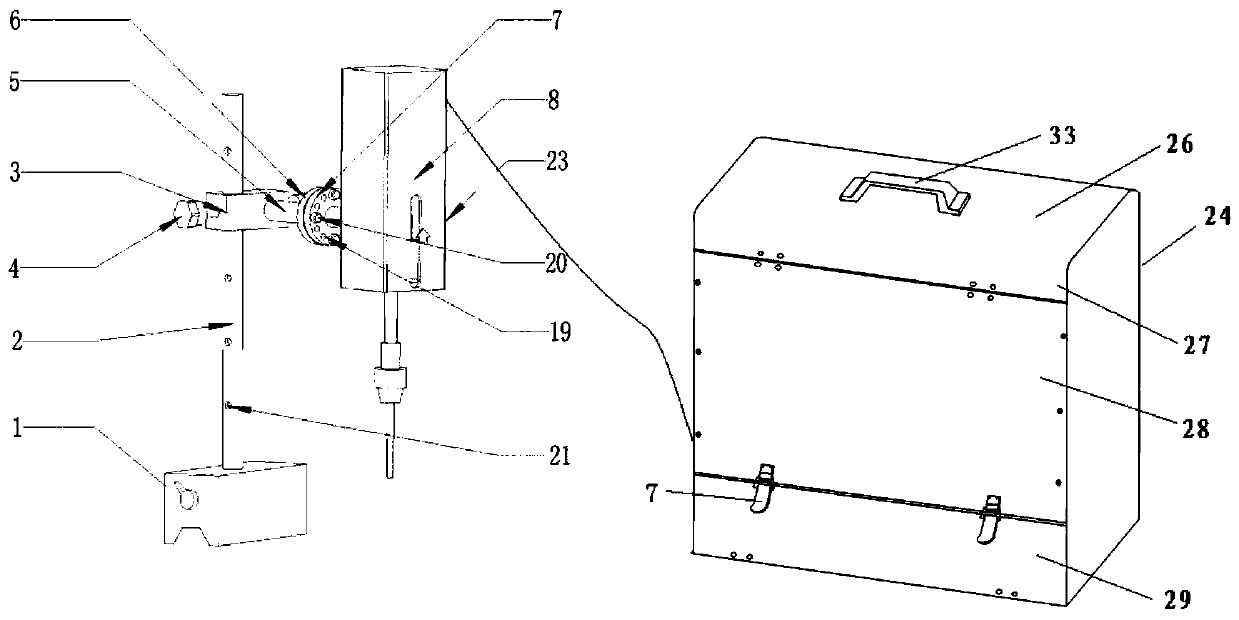

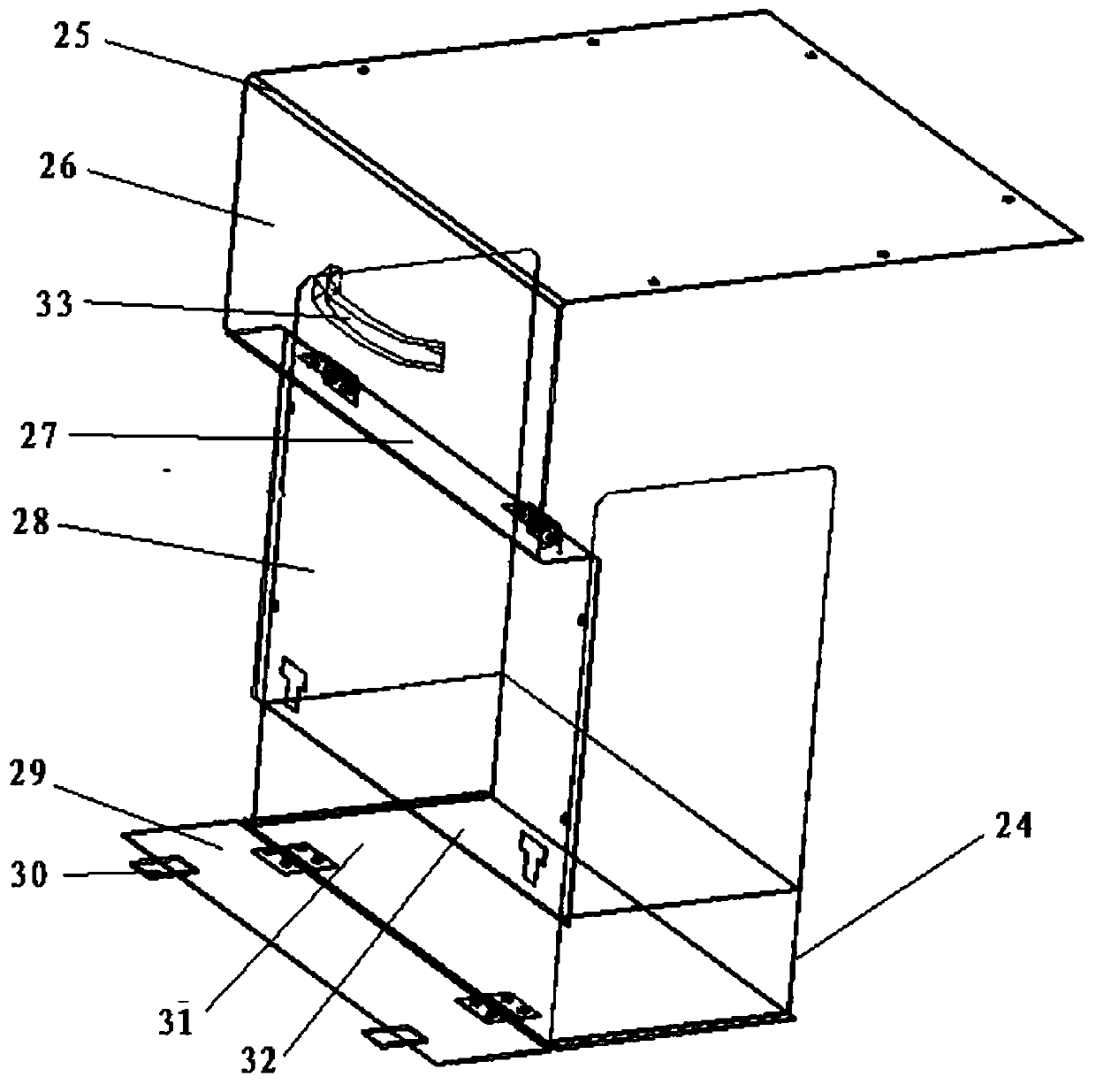

[0041] As shown in the accompanying drawings, a high-precision rotatable electric spark perforator of this patent is characterized in that: it includes a host and an electrical control box; the electrical control box is electrically connected to the host, and the electrical control box is used to control the work of the host; the host It includes a base 1, a rotating lifting mechanism and a machine head 8.

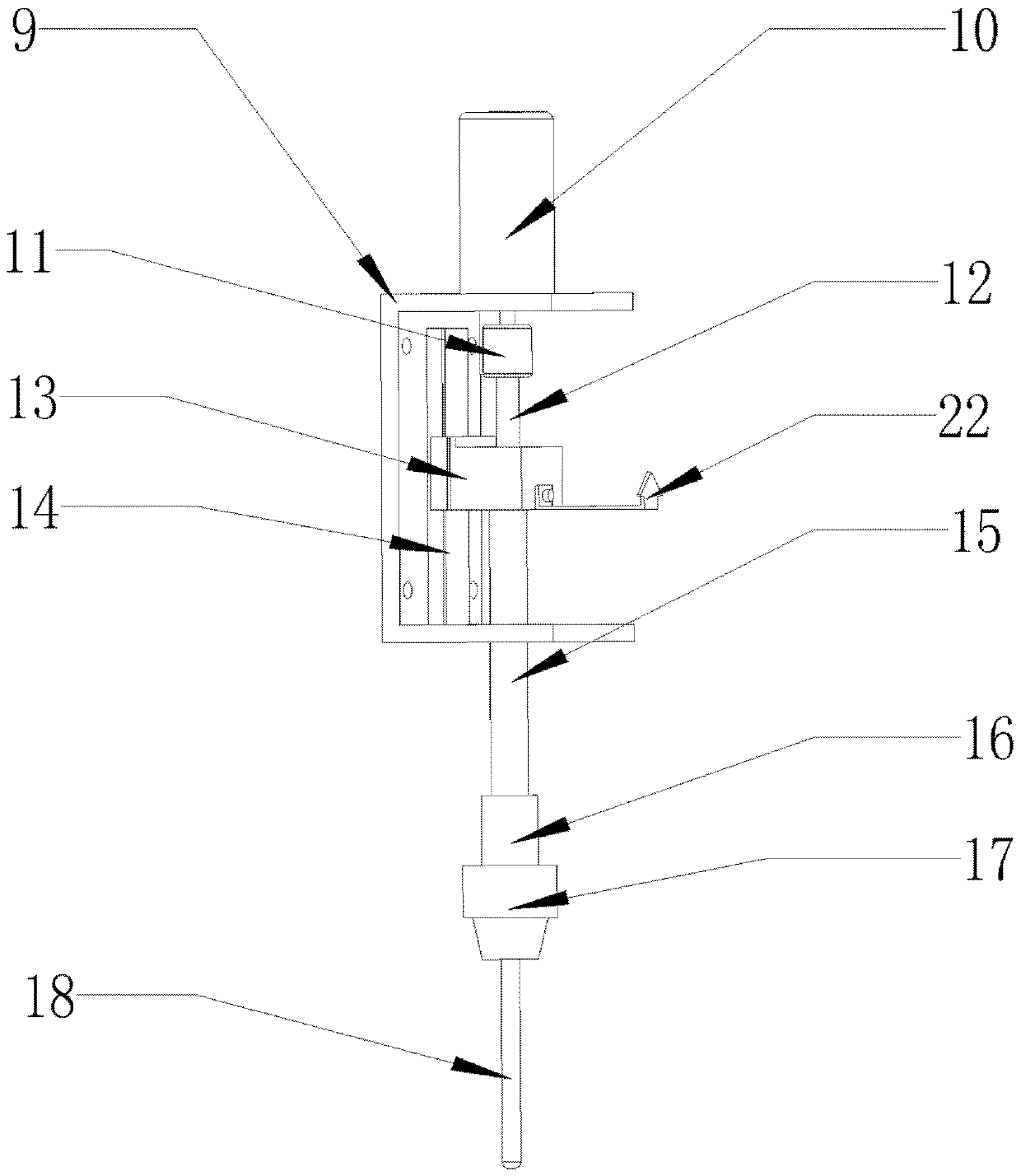

[0042] The rotary lifting mechanism includes a column 2, a cross connector 3, two star-shaped locking screws 4, a cross bar 5, a left indexing plate 6, a right indexing plate 7, a positioning fixing screw 20 and a connecting rod; There are two threaded holes and two through holes that are perpendicular to each other and do not interfere with each other. The two threaded holes respectively pass through the two through holes; the column 2 is provided with a row of positioning holes 21 at equal intervals, and the column 2 passes through the cross connector 3; a row of equally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com