Blast furnace main runner surface mulch

A covering material and blast furnace technology, which is applied in the field of unshaped refractory materials for iron and steel metallurgy, can solve problems such as discounted service life of blast furnace tap hooks, poor isolation effect, and damage to the surface of the trench body, achieving obvious economic and social benefits. Reduce construction and maintenance costs and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

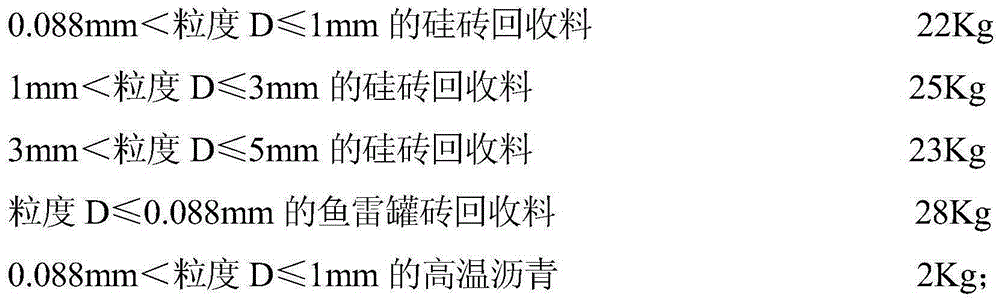

[0025] Prepare 100Kg blast furnace main ditch ditch cover material, the raw material that adopts and weight percentage thereof are as follows:

[0026]

[0027] Among them, SiO in silica brick recycled materials 2 The content is 85wt%, the Al in the torpedo tank brick recycled material 2 o 3 The content is 65wt%, SiC is 12wt%.

[0028] Accurately weigh the above-mentioned raw materials, pour them into a mixer, mix them for 10 minutes until they are completely mixed, pack them in bags after discharge, conduct spot checks, and put them into storage to obtain the required covering material for the main trench of the blast furnace.

Embodiment 2

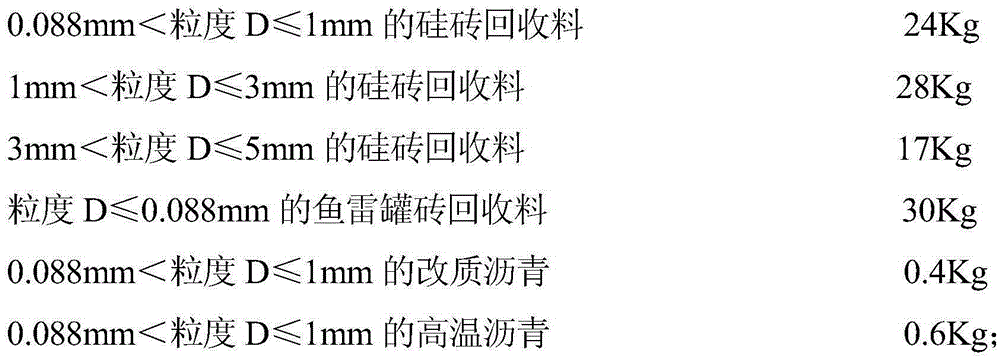

[0030] Prepare 100Kg blast furnace main ditch ditch cover material, the raw material that adopts and weight percentage thereof are as follows:

[0031]

[0032] Among them, SiO in silica brick recycled materials 2 The content is 88wt%, the Al in the torpedo tank brick recycled material 2 o 3 The content is 55wt%, SiC is 10wt%.

[0033] Accurately weigh the above-mentioned raw materials, pour them into a mixer, mix them for 12 minutes until they are completely mixed, pack them in bags after discharge, conduct spot checks, and put them into storage to obtain the required covering material for the main trench of the blast furnace.

Embodiment 3

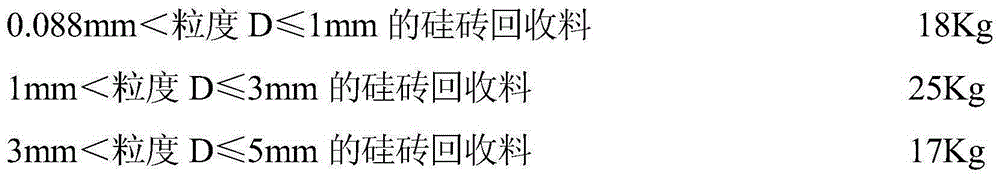

[0035] Prepare 100Kg blast furnace main ditch ditch cover material, the raw material that adopts and weight percentage thereof are as follows:

[0036]

[0037]

[0038] Among them, SiO in silica brick recycled materials 2 The content is 88wt%, the Al in the torpedo tank brick recycled material 2 o 3 The content is 55wt%, SiC is 10wt%.

[0039] Accurately weigh the above-mentioned raw materials, pour them into a mixer, mix them for 12 minutes until they are completely mixed, pack them in bags after discharge, conduct spot checks, and put them into storage to obtain the required covering material for the main trench of the blast furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com