Composition of special ultralow-temperature grease for casters and preparation method of special ultralow-temperature grease

A lubricating grease and ultra-low temperature technology, which is applied in the field of lubricating grease, can solve the problems of high lubricating grease production cost, and achieve the effects of low production cost, good oil separation resistance, and excellent low-temperature start-up performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

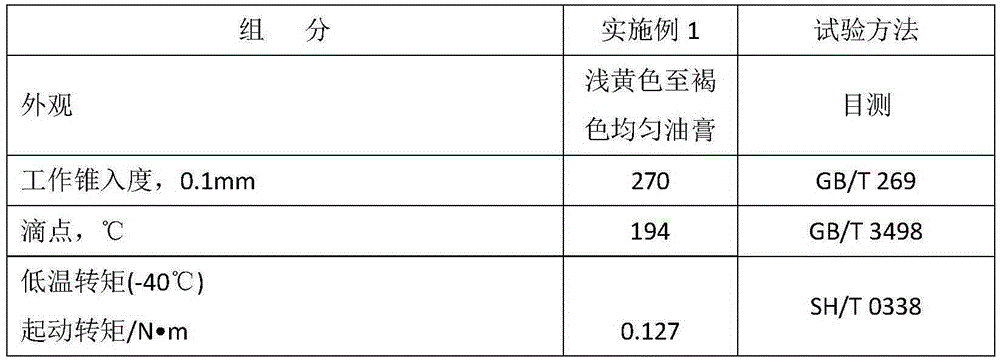

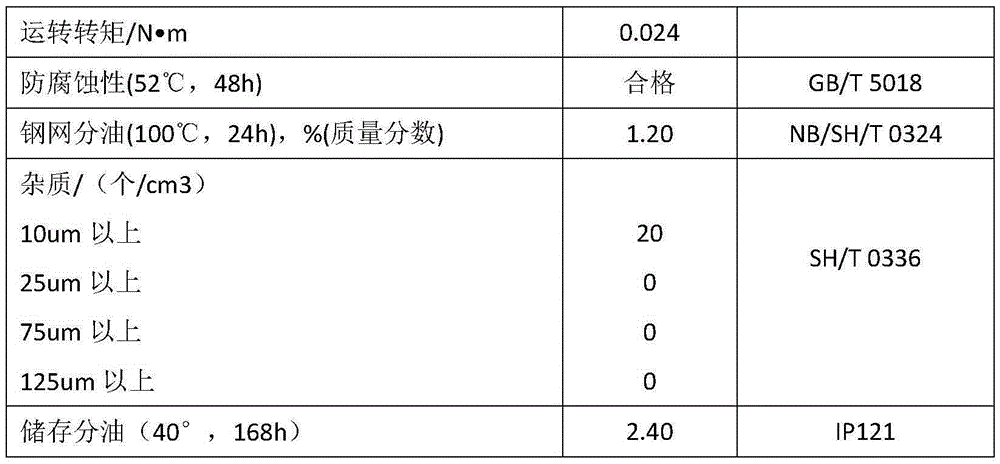

Embodiment 1

[0033] base oil 85%,

[0034] Thickener 15%,

[0035] Additives are added according to the proportion of the above components

[0036] Grease structure improver 1%,

[0037] Antioxidant 0.5%,

[0038] Rust inhibitor 0.5%.

[0039] 270 grams of 12-hydroxystearic acid, 135 grams of hydrogenated castor oil fatty acid, 45 grams of stearic acid, 3.75 grams of naphthenic acid, 30 grams of grease structure improver and 765 grams of naphthenic base oil are added to the reactor, heated to At 80-85°C, dissolve 59.5 grams of lithium hydroxide with five times the amount of water to prepare an alkaline solution. Add lye to the reaction kettle at 80-85°C, heat up to 100-115°C for saponification reaction, and control the reaction time at 60-80 minutes; after the saponification reaction, raise the temperature to 140°C to drain water, and control the time at 20-30 minutes. Sampling to measure free acid-base, controlled at 0.04-0.15% NaOH, after the free acid-base is within the control ran...

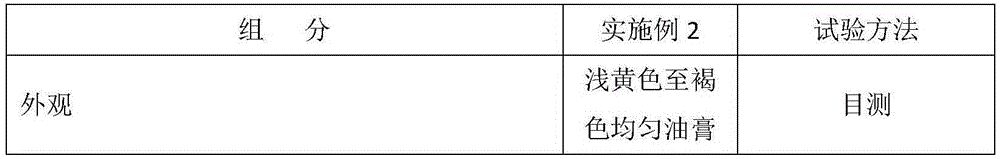

Embodiment 2

[0045] base oil 87%,

[0046] Thickener 13%,

[0047] Additives are added according to the proportion of the above components

[0048] Grease structure improver 1%,

[0049] Antioxidant 0.5%,

[0050] Rust inhibitor 0.5%.

[0051] 234 grams of 12-hydroxystearic acid, 117 grams of hydrogenated castor oil fatty acid, 39 grams of stearic acid, 3.25 grams of naphthenic acid, 30 grams of grease structure improver and 783 grams of naphthenic base oil are added to the reactor, heated to 80-85°C, dissolve 31 grams of lithium hydroxide with five times of water to prepare an alkaline solution. Add lye to the reaction kettle at 80-85°C, heat up to 100-115°C for saponification reaction, and control the reaction time at 60-80 minutes; after the saponification reaction, raise the temperature to 140°C to drain water, and control the time at 20-30 minutes. Sampling to measure free acid-base, controlled at 0.04-0.15% NaOH, after the free acid-base is within the control range, rapidly rais...

Embodiment 3

[0056] base oil 89%,

[0057] Thickener 11%,

[0058] Additives are added according to the proportion of the above components

[0059] Grease structure improver 1%,

[0060] Antioxidant 0.5%,

[0061] Rust inhibitor 0.5%.

[0062]198 grams of 12-hydroxystearic acid, 99 grams of hydrogenated castor oil fatty acid, 33 grams of stearic acid, 2.75 grams of naphthenic acid, 30 grams of grease structure improver and 801 grams of naphthenic base oil are added to the reactor, heated to 80-85°C, dissolve 29 grams of lithium hydroxide with five times the water to prepare an alkaline solution. Add lye to the reaction kettle at 80-85°C, heat up to 100-115°C for saponification reaction, and control the reaction time at 60-80 minutes; after the saponification reaction, raise the temperature to 140°C to drain water, and control the time at 20-30 minutes. Sampling to measure free acid-base, controlled at 0.04-0.15% NaOH, after the free acid-base is within the control range, rapidly raise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com