An air source flexible gas heat pump unit and its operating method

A gas-fired heat pump and air source technology, which is applied in the operation mode of the machine, the combination of heating and cooling, and the refrigerator, etc., can solve the problems of frosting of the outdoor heat exchanger, reduced energy utilization rate, failure to achieve energy saving and environmental protection, etc. The effect of reducing environmental pollution, improving operation effect and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Structure, principle and mode of operation of the present invention are further elaborated below in conjunction with accompanying drawing:

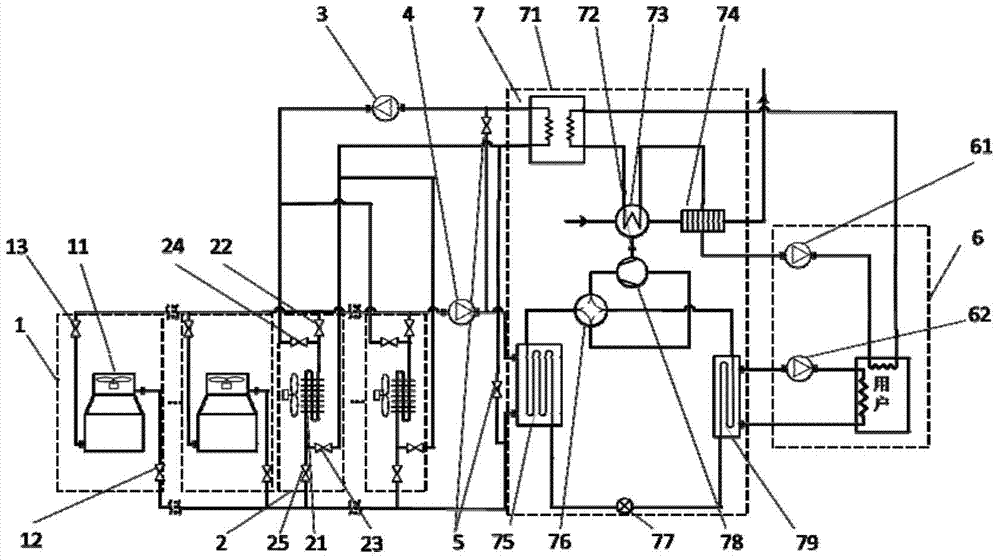

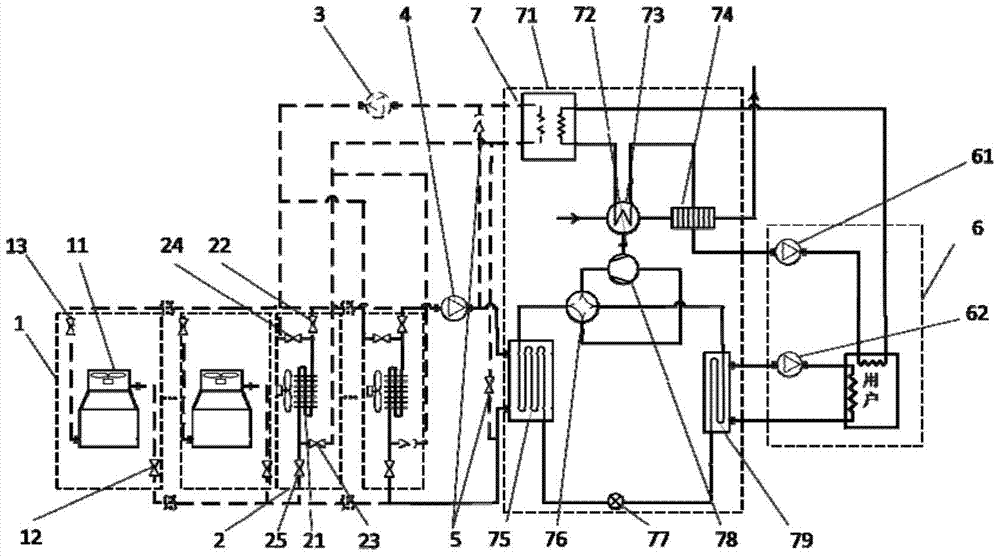

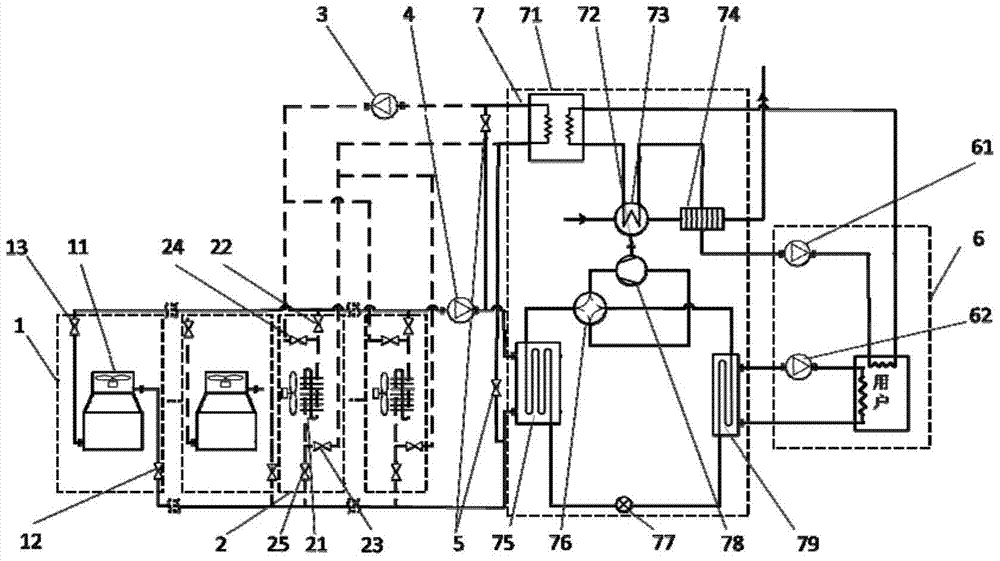

[0020] figure 1 It is an air source flexible gas heat pump unit disclosed in the present invention. The unit includes an outdoor unit, a gas heat pump unit and a user unit; the gas heat pump unit includes a waste heat heat exchanger 71, an engine 73 and a flue gas heat recovery heat exchanger The gas engine part composed of 74 and the heat pump part composed of a first heat exchanger 75, a compressor 78, a second heat exchanger 79, a four-way valve 76 and a throttle valve 77 are connected by a linkage shaft 72; its characteristics In that: the outdoor unit includes at least one set of cooling tower modules 1, at least two sets of air-cooled heat exchanger modules 2, a first liquid pump 3 and a second liquid pump 4, and each set of cooling tower modules contains a cooling tower 11 and a first valve 12 and the second valve 13; each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com