Detection method of sulfur fixation performance of lithium sulfur battery cathode material

A technology of positive electrode material and detection method, which is applied in analytical materials, measuring devices, instruments, etc., can solve the problems of loss of active material, destruction of electrode structure, low utilization rate of sulfur of positive active material, etc., and achieves high accuracy and good repeatability. , The intuitive effect of the test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Assemble the newly prepared positive electrode A into a button battery, connect it to the blue battery tester for battery cycle test, cycle 5 times and finish charging, disassemble the battery in the glove box, take out the positive electrode B, and use 1, 3 -After washing with dioxolane for several times, turn it out to dry at 70°C, and then carry out the characterization test.

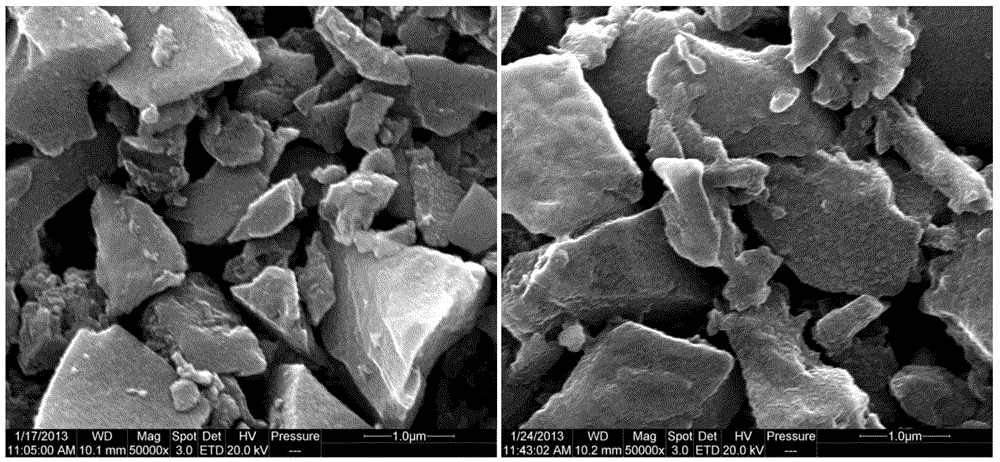

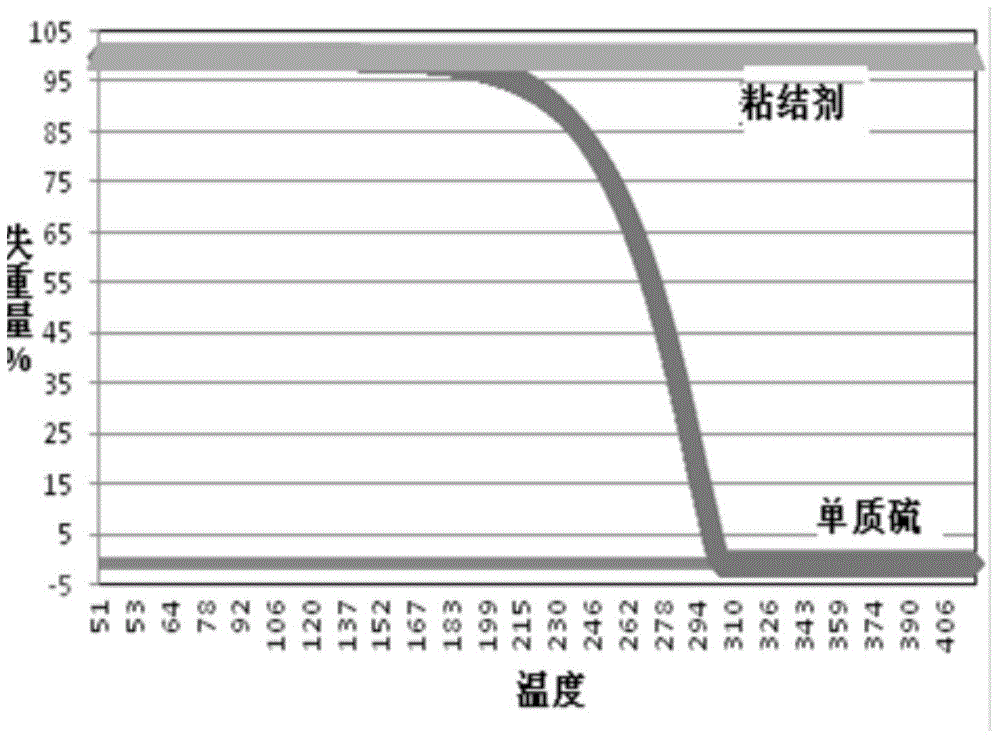

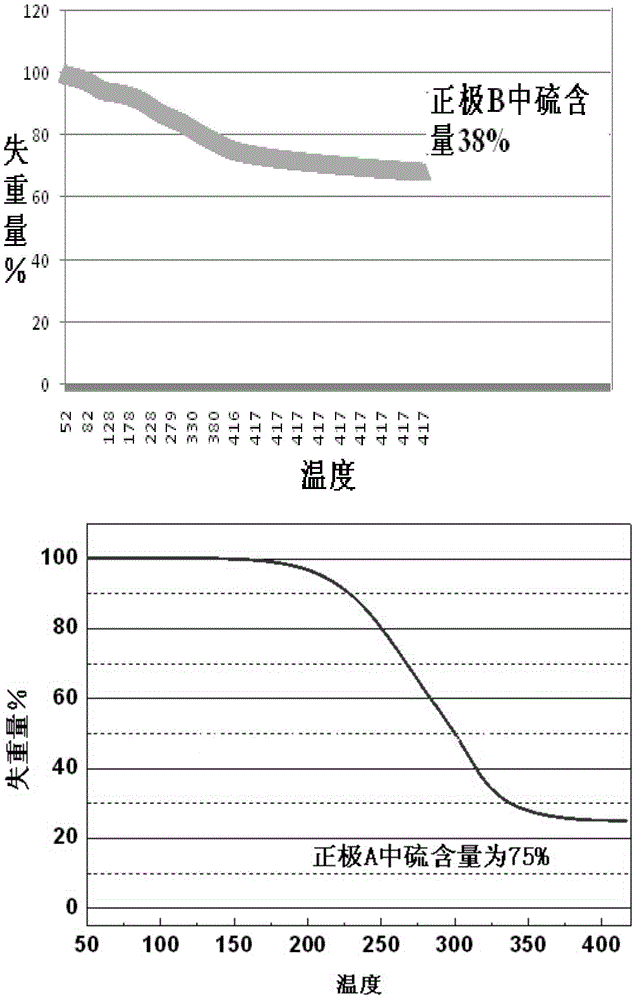

[0035] Qualitative analysis: the positive electrode A and the positive electrode B at the end of 5 cycles of charging were respectively loaded in a scanning electron microscope to test the changes in electrode morphology before and after battery operation ( figure 1 shown). Depend on figure 1 It can be seen that significant changes have taken place on the surface of the material before and after the cycle. Before the cycle, the surface of the material is relatively smooth, and no obvious sulfur particles exist. After the cycle, the surface of the material is obviously attached to the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com