A cavity filter cover plate

A cavity filter and cover plate technology, which is applied in the field of signal processing, can solve the problems of uneven interface between tuning hole and tuning screw sleeve, unstable tuning screw sleeve, and high defective rate of threaded holes, so as to save material costs and save The effect that a process and processing are easy

Active Publication Date: 2019-01-22

JOHNSON PRECISION ENG SUZHOU

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current common filters include cavity, cover plate and tuning self-locking screws and other components. Most of the filter cover plates are now processed by stamping holes on the plate to process the tuning holes. On the one hand, the threaded holes are processed by stamping. The defective rate is high and the manufacturing cost is too high. On the other hand, the punched tuning hole needs to be additionally installed with a tuning screw sleeve. The tuning screw sleeve is fixed on the tuning hole by welding, riveting, gluing, etc. The tuning screw sleeve The installation not only requires labor costs and processing costs, but at the same time, the additional tuning screw sleeve installed on the tuning hole is not stable, and it is easy to loosen after a period of time, and the interface between the tuning hole and the tuning screw sleeve is not stable. Flat, which ultimately affects the actual tuning effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Login to View More

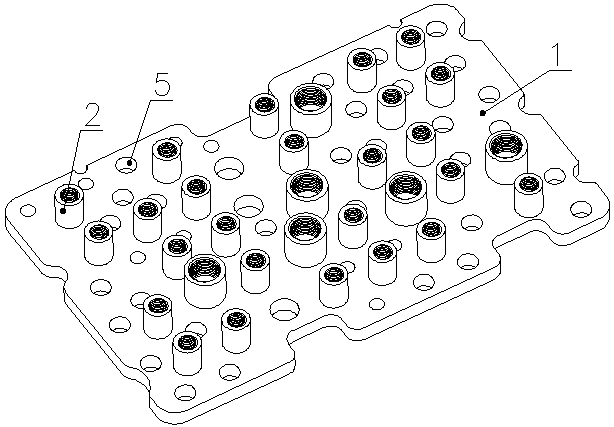

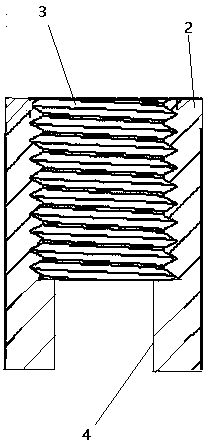

Abstract

The invention discloses a cover board of a cavity filter. The cover board is used for closing a cavity of the cavity filter, and comprises a cover board body, wherein the cover board body is made of copper aluminum alloy; the alloy is copper-aluminum composite integrated alloy, namely one surface is made of copper and the other surface is made of aluminum; the aluminum surface is aligned at the cavity when the cover board is used; a tuning threaded hole is formed in the cover board body; the tuning threaded hole specifically is a lug boss which extends towards the direction of the cavity and is molded integrally with the cover board body; the middle part of the lug boss is hollow; an inner ring of the lug boss is made of copper; an outer ring is made of aluminum; the threaded hole is formed in the lug boss along the axis direction; a tuning hole which is connected with the threaded hole is also formed in the lug boss along the axis direction; the tuning hole is closer to the cavity of the filter than the threaded hole; and the diameter of the tuning hole is smaller than that of the tuning self-locking bolt of the filter. According to the cover board of the cavity filter, the cost and the tuning performance are considered; and resources are saved.

Description

technical field The invention relates to the field of signal processing, in particular to a cavity filter cover plate. Background technique At present, the signal processing of the cavity filter is usually completed by the tuning self-locking screw on the filter cover. Generally speaking, the problem dealt with by the tuning screw is the problem of signal intermodulation. Specifically, it refers to two different frequency signals. A signal of a new frequency generated by superposition within a system. The current common filters include cavity, cover plate and tuning self-locking screws and other components. Most of the filter cover plates are now processed by stamping holes on the plate to process the tuning holes. On the one hand, the threaded holes are processed by stamping. The defective rate is high and the manufacturing cost is too high. On the other hand, the punched tuning hole needs to be additionally installed with a tuning screw sleeve. The tuning screw sleeve is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01P1/207

Inventor 王强

Owner JOHNSON PRECISION ENG SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com