An anti-clogging and easy-to-clean microporous ceramic drip irrigation device

A microporous ceramic, easy-to-clean technology, applied in watering devices, horticulture, botanical equipment and methods, etc., can solve problems such as inability to clean, complex labyrinth channel structure, easy deposition, etc., to improve irrigation uniformity, work The principle is simple, and the effect of improving the anti-blocking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

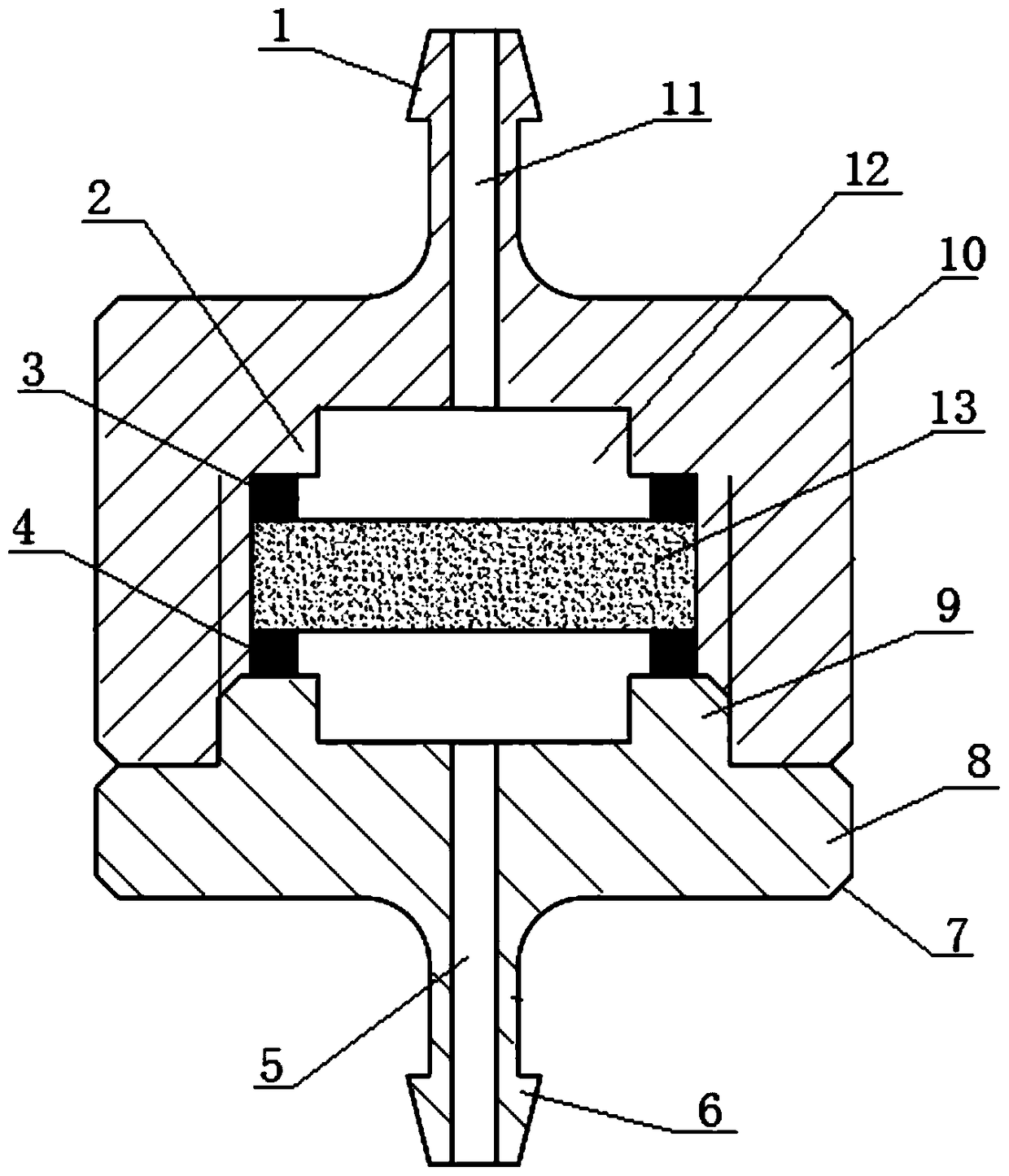

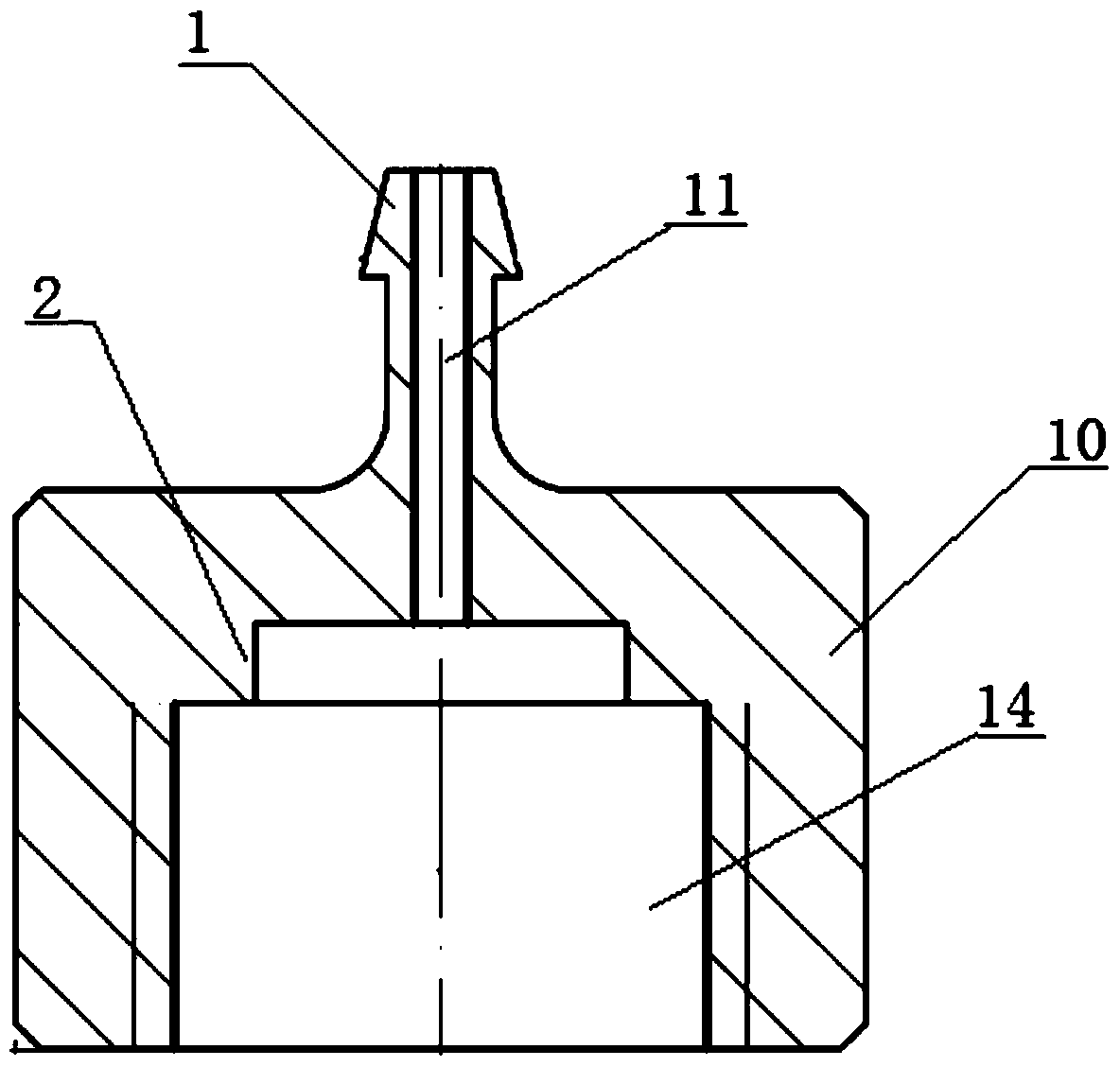

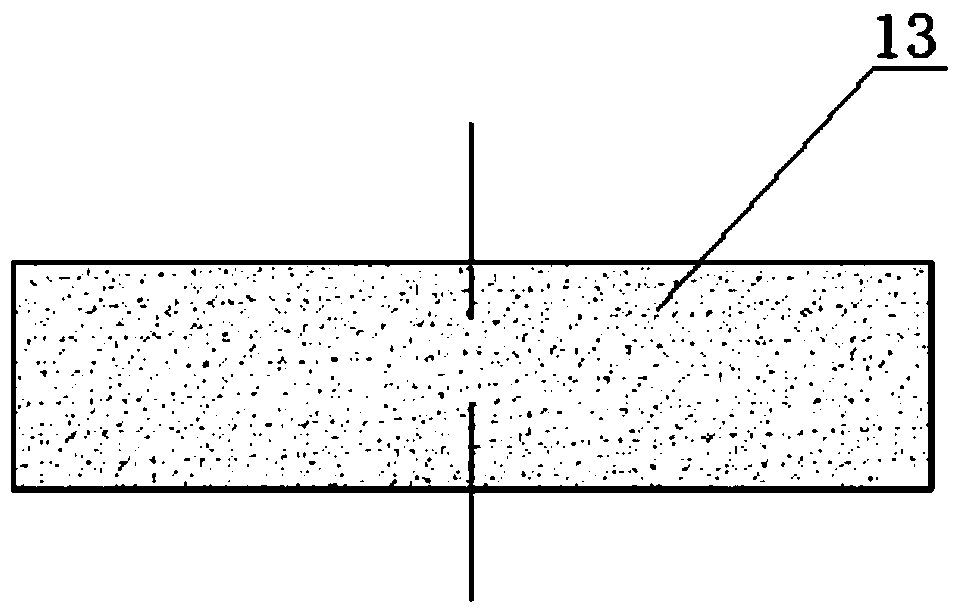

[0030] Comply with the above technical solutions, such as figure 1 As shown in Fig. 7, an anti-clogging and easy-to-clean microporous ceramic drip irrigation emitter includes a base 8 on which a cavity shell 10 is detachably installed, and a cavity 14 is provided inside the cavity shell 10, and the cavity 14 is installed with a water seepage sheet 13, and pores are distributed in the water seepage sheet 13; a water inlet hole 11 connected with the cavity 14 is provided on the cavity shell 10, and a water inlet hole 11 is provided on the base 8. The water outlet hole 5, the water flow enters the cavity 14 from the water inlet hole 11 and flows out of the base 8 from the water outlet hole 5 after being filtered by the water seepage sheet 13.

[0031] The basic structure of the present invention includes a base 8 and a cavity shell 10, wherein the inside of the cavity shell 10 is a cavity 14, and the cavity 14 has multiple functions, one of which is used to install the water seep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com