3D printing bone defect filling material

A technology for filling materials and printing bone, applied in the field of medical materials, can solve problems such as single structure and inability to apply to bone defects, and achieve the effects of enhancing friction, improving stability, and promoting bone ingrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

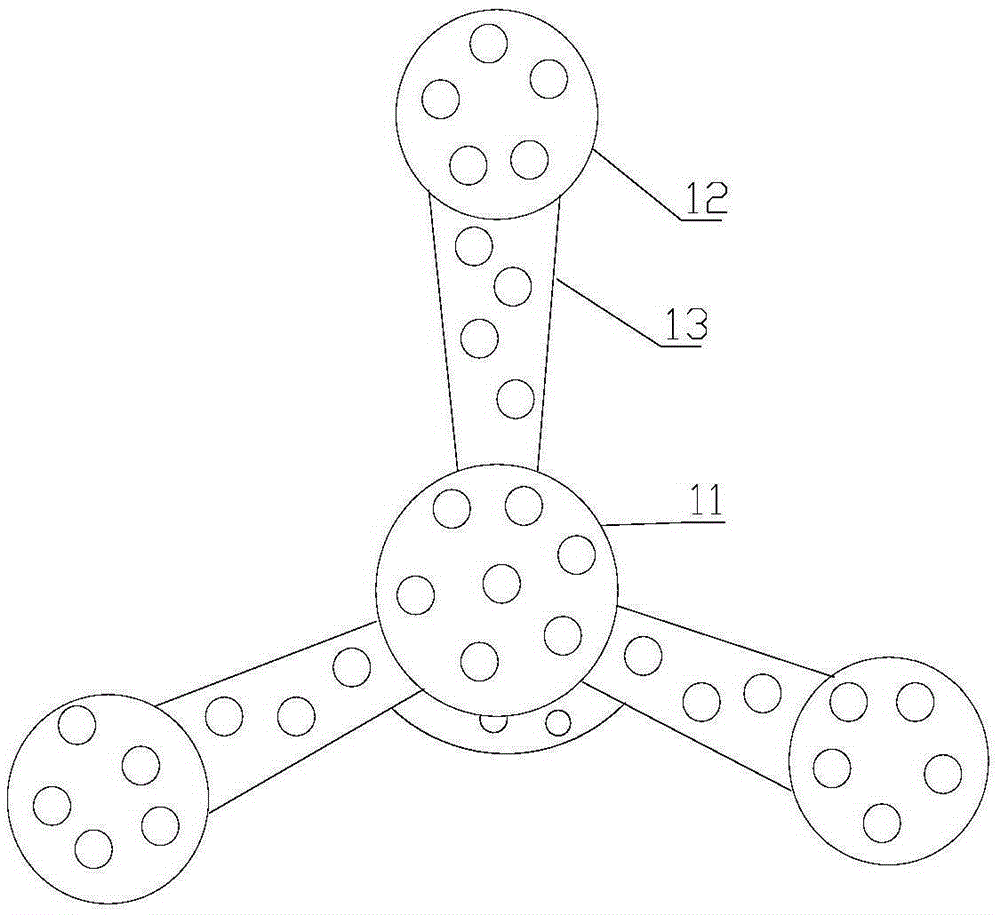

[0023] Such as figure 1 , 5 As shown, it is the 3D printing bone defect filling material of the present invention, the filling material includes a granular body 1 and a flexible mesh 2, and the flexible mesh 2 wraps the granular body 1. The granular body 1 is a stick body with four supporting vertices.

[0024] The stick body includes a center ball 11 inside and side balls 12 evenly distributed around the center ball 11, the number of side balls 12 is four, and each side ball 12 is connected to the center ball 11 through a columnar body 13 , the length of each columnar body 13 is equal. The diameter of the columnar body 13 gradually decreases from the side sphere 12 to the center sphere 11 .

[0025] Micropores are evenly distributed on the surface of the ball stick body, and the pore diameters of the micropores gradually decrease from the surface of the particle body 1 to the inside, that is, the cross-section of the micropores is in the shape of a bone trabecula.

[0026...

Embodiment 2

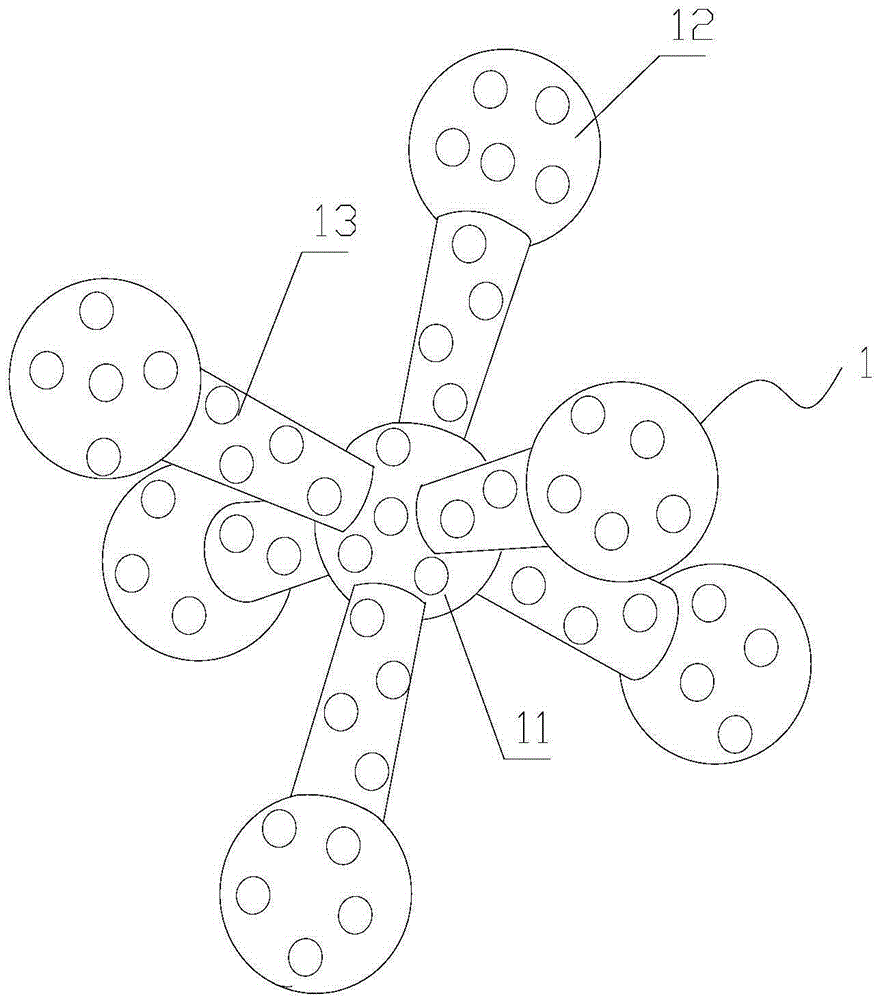

[0029] Such as figure 2 , 5 As shown, in this embodiment, the difference from Embodiment 1 is that the granular body 1 is a stick body with 6 supporting vertices, that is, the number of side balls 12 is 6. The columnar body 13 is cylindrical, and the ratio of the diameter of the side ball 12 to the diameter of the columnar body 13 is 1.3:1, 1.5:1, 1.7:1, 1.8:1 or 2:1, which can be 1.3-2:1 any value.

Embodiment 3

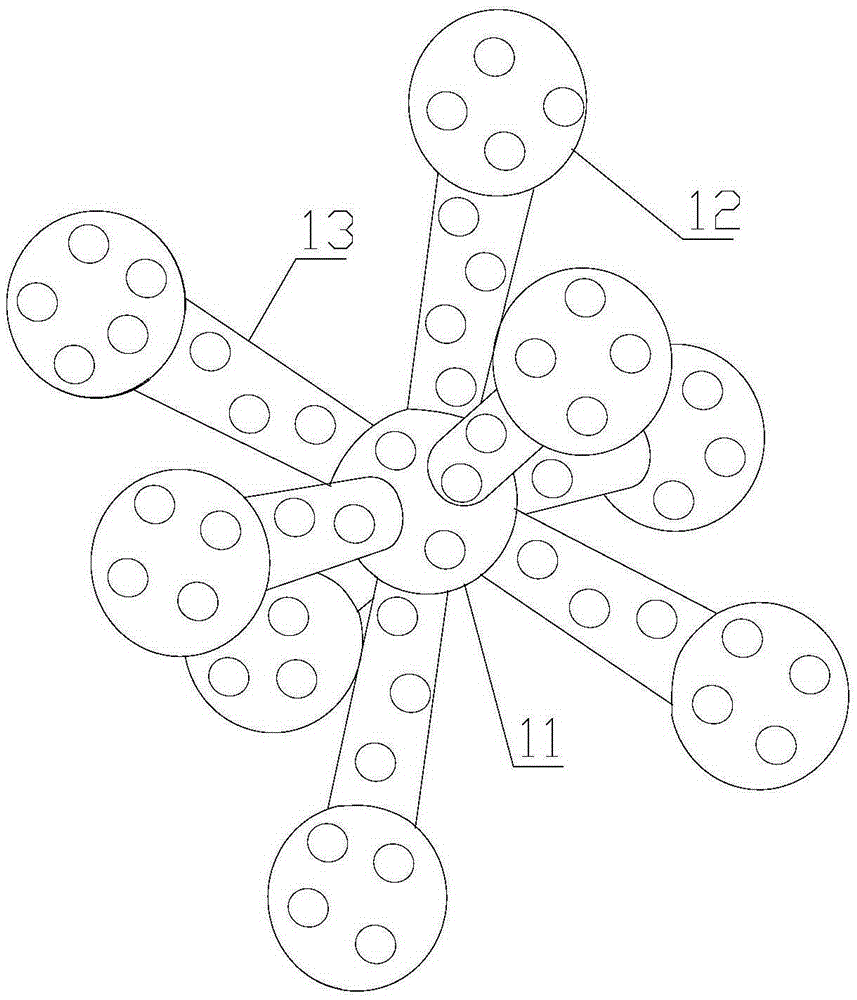

[0031] Such as image 3 , 5 As shown, in this embodiment, the difference from Embodiment 1 is that the particle body 1 is a stick body with 8 supporting vertices, that is, the number of side balls 12 is 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com