A core board glue coating and veneer production line

A core board gluing and production line technology, which is applied in the field of floor processing, can solve the problems of slow processing speed, uneven gluing, and easy solidification, and achieve the effects of reducing contact area, avoiding uneven gluing, and preventing glue from solidifying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

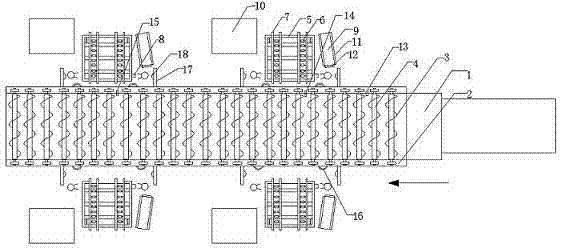

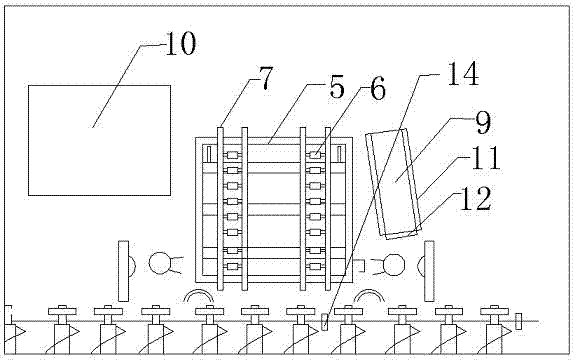

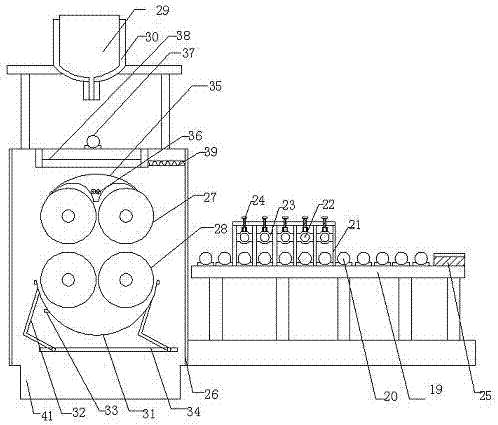

[0025] Such as Figure 1-7 As shown, the present invention is a production line for gluing and veneering core boards. The production line includes a gluing device, and a bottom plate and a skin device are arranged on one side of the gluing device. Carry out gluing after material and then carry out the lamination of base plate and dough through base plate and dough sticking device, then carry out cold pressing treatment, described gluing device comprises feeding device, and described feeding device comprises two parallel feeding racks 19 , several rollers 20 driven and rotated by motors are arranged horizontally on the two described feeding racks 19. Preferably, the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com