Method for improving slag permeation resistance of refractory aluminum-chromium material

A refractory material and slag penetration technology, which is applied in the field of refractory materials, can solve the problems of high price of aluminum chromium materials, high maintenance and replacement costs, and long cycle, so as to improve the resistance to slag penetration, prolong the service life, and improve the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

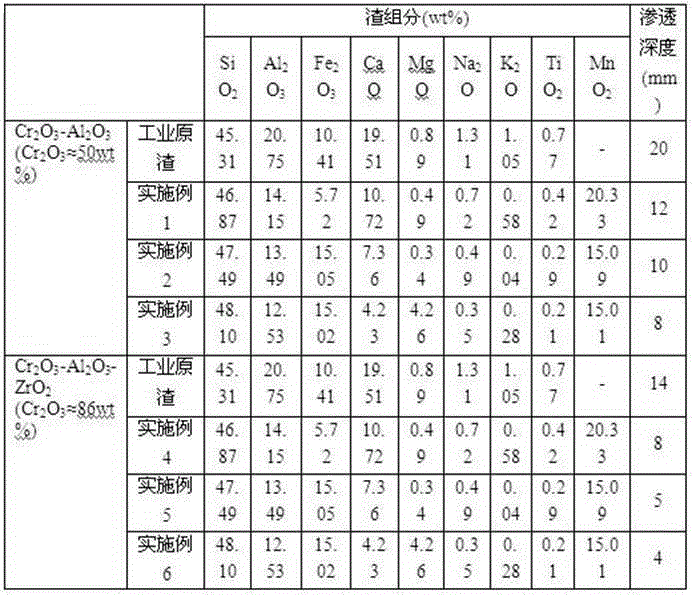

[0013] Embodiment 1: The chemical composition of the industrial cinder analyzed in a certain area of Anhui, my country is: 45.31wt%SiO 2 , 20.75wt%Al 2 o 3 , 10.41wt%Fe 2 o 3 , 19.51wt%CaO, 0.89wt%MgO, 1.31wt%Na 2 O, 1.05wt%K 2 O and 0.77wt%TiO 2 . Mechanically grind the above coal slag and select analytically pure MnO 2 The powder is used as an additive, and the cinder added with the additive is fully mixed and pre-melted, and the Mn content in the adjusted slag is 20.33wt%. Cr 2 o 3 Cr content about 50wt% 2 o 3 -Al 2 o 3 Bricks were prepared into crucible samples, and the slag of the above ratio was used to carry out the static crucible slag resistance test according to the national standard, and the test temperature was 1600 o C, the time is 5h. The sample after the experiment was analyzed, and the maximum penetration depth of the sample was 12mm.

Embodiment 2

[0014] Example 2: The industrial slag in Example 1 is mechanically ground, and the selected additive is analytically pure MnO 2 and Mn 3 o 4 powder, and Fe 2 o 3 and Fe 3 o 4 Powder, the cinder with additives is fully mixed and pre-melted, and the Mn content in the adjusted slag is 15.09wt%, and the Fe content is 15.05wt%. Cr 2 o 3 Cr content about 50wt% 2 o 3 -Al 2 o 3 Bricks were prepared into crucible samples, and the slag of the above ratio was used to carry out the static crucible slag resistance test according to the national standard, and the test temperature was 1600 o C, the time is 5h. The sample after the experiment was analyzed, and the maximum penetration depth of the sample was 10mm.

Embodiment 3

[0015] Embodiment 3: the industrial slag in embodiment 1 is carried out mechanical grinding, and the selected additive is analytically pure MnO 2 and Mn 2 o 3 Powder, Fe 2 o 3 Powder and MgO powder, the cinder added with additives is fully mixed and pre-melted. After adjustment, the Mn content in the slag is 15.01wt%, the Fe content is 15.02wt%, and the Mg content is 4.26wt%. Cr 2 o 3 Cr content about 50wt% 2 o 3 -Al 2 o 3 Bricks were prepared into crucible samples, and the slag of the above ratio was used to carry out the static crucible slag resistance test according to the national standard, and the test temperature was 1600 o C, the time is 5h. The sample after the experiment was analyzed, and the maximum penetration depth of the sample was 8mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com