Two-wire system ultrasonic level transmitter and method thereof

A transmitter and two-wire technology, applied in instruments, liquid level indicators, machines/engines, etc., can solve problems such as poor compressive strength, high sensitivity, and large amplitude, and achieve high sensitivity, large amplitude, and small aftershocks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

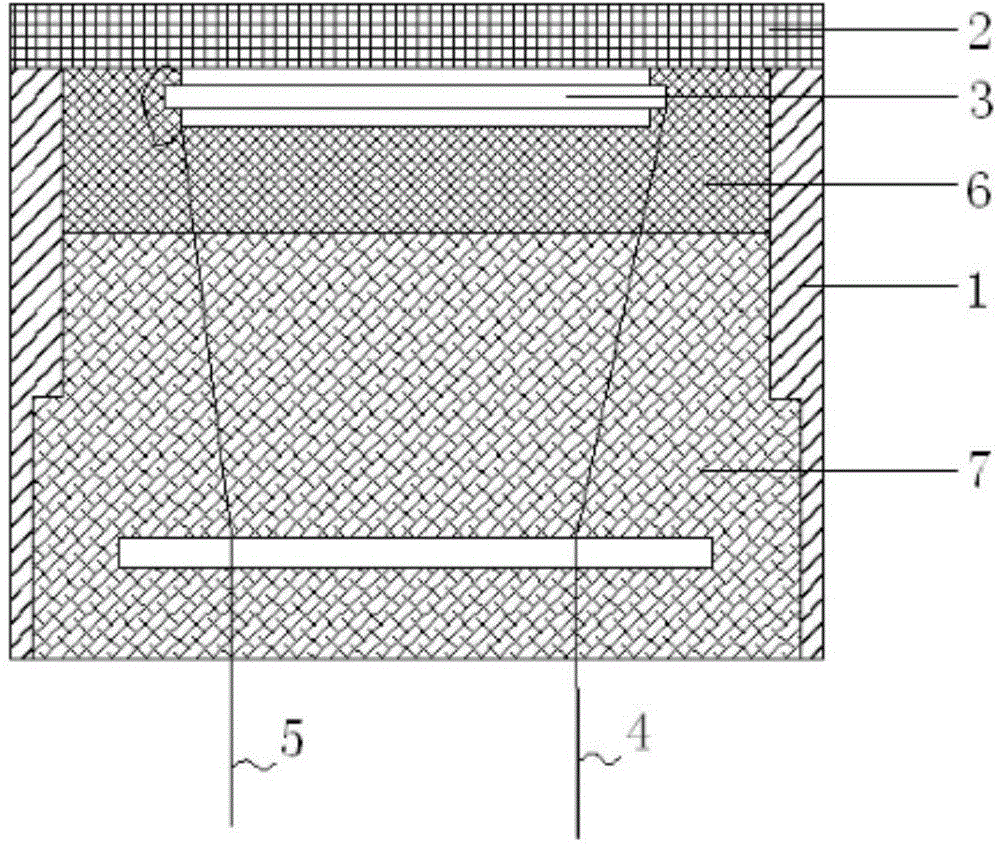

[0017] like figure 1 As shown, the present invention provides a two-wire ultrasonic level transmitter and its method, comprising a hollow metal casing 1, one end of the metal casing 1 is covered with a matching layer 2, and the inside of the matching layer 2 is bonded with a parallel piezoelectric Bimorph 3, the parallel piezoelectric bimorph 3 is that two opposite electrode surfaces of two piezoelectric wafers are respectively bonded on both sides of the metal substrate, and the other two electrode surfaces of the two piezoelectric wafers are electrically connected; The common connection ends of the two piezoelectric wafers are respectively connected with the first connection terminal 4 and the second connection terminal 5 with the metal substrate.

[0018] Preferably, a sound-absorbing material is filled between the parallel-connected piezoelectric b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com