Method for calibrating flatness of X-Y plane of microscopic scanning platform

A scanning platform and calibration method technology, applied in microscopes, optics, instruments, etc., can solve problems such as increased hardware complexity, out-of-focus, and increased cost expenditures, and achieve the goal of reducing improvement costs, reducing manufacturing costs, and improving continuous scanning performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

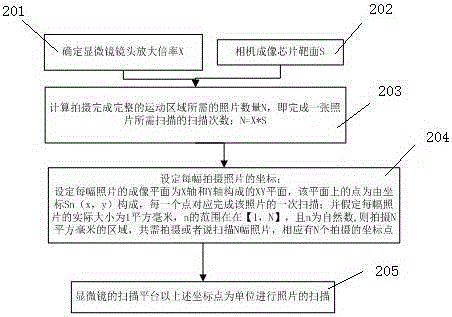

[0096] The following embodiments describe the calibration method of the microscopic scanning platform in detail. In this embodiment, the moving area of the scanning platform is 100mm * 75mm=7500mm 2 The detailed process steps of its calibration are as follows:

[0097] first step, such as figure 2 As shown in steps 201 and 202, determine the magnification of the microscope lens, the target surface S of the camera imaging chip, and the lens magnification X of the microscope, so as to calculate the physical area S on the XY platform corresponding to the camera imaging photo.

[0098] The second step, such as figure 2 As shown in step 203, calculate the moving area S of the scanning platform, that is, S=100mm×75mm=7500mm 2 , set the camera image size to cover the entire motion area, and calculate the number N of photos required to capture the complete motion area, then N=7500.

[0099] The third step is to determine the XY axis coordinates of each photo taken. If the actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com