Hybrid excitation permanent magnet brushless motor for electric vehicle

A permanent magnet brushless motor and combined excitation technology, which is applied to electric vehicles, motors, vehicle parts, etc., can solve the problems of high cost and unstable supply of rare earth permanent magnet materials, reduce the risk of irreversible demagnetization, and increase the amount of use , Improve the effect of permanent magnet torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

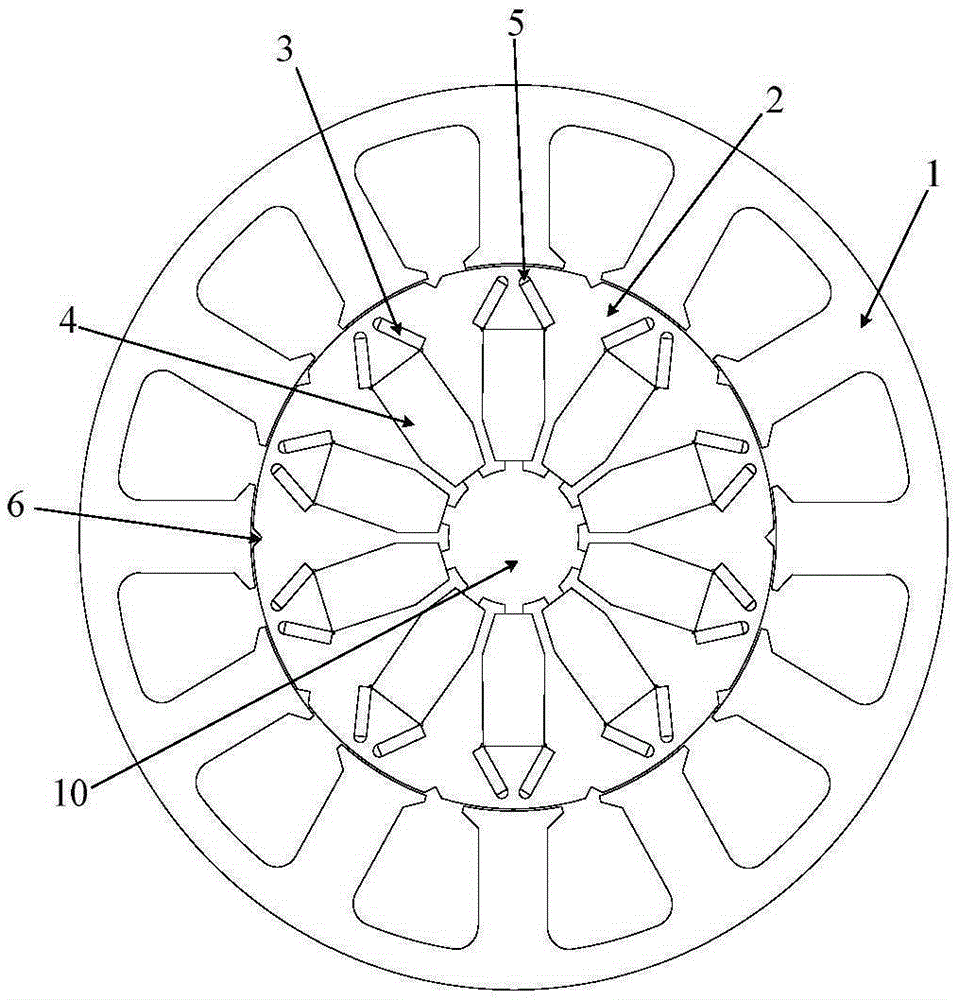

[0031] see figure 1 , The present invention is a combination of less rare earth excitation width and speed regulation permanent magnet brushless motor, which adopts an external stator structure, including a stator 1, a rotor 2 and a rotating shaft 10. The rotor 2 is coaxially located inside the stator 1 , and the center of the rotor 2 is used for placing the rotating shaft 10 . There is an air gap between the inner wall of the stator 1 and the outer wall of the rotor 2, and the thickness of the air gap is related to the power level of the motor, the selected permanent magnet material, and the processing and assembly process of the stator 1 and the rotor 2. Both the stator 1 and the rotor 2 are laminated with silicon steel sheets with a thickness of 0.35mm, and the lamination coefficient is 0.95.

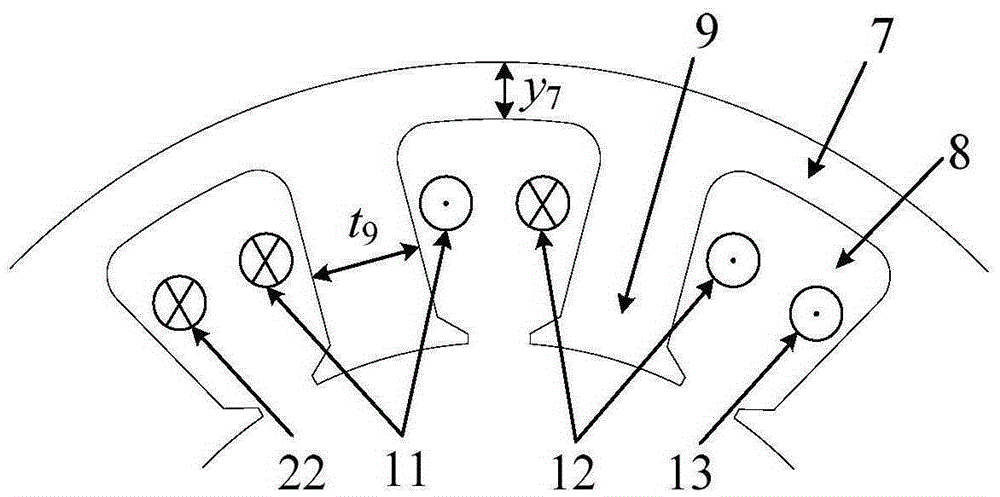

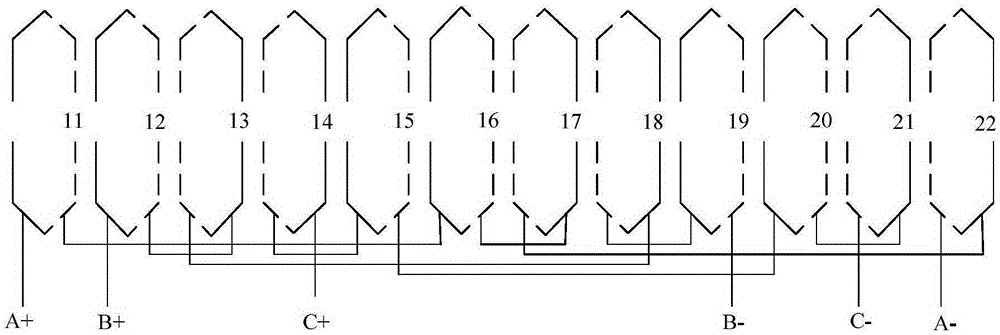

[0032]The rotor 2 is embedded with two layers of permanent magnet steel inside and outside, the two layers of permanent magnet steel are evenly arranged along the circumferential di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com