Fully automatic and intelligent noodle processing method

A production method and fully automatic technology, which is applied in the directions of cutting noodles, dough processing, dough mixer, etc., can solve the problems of large floor area, low degree of automation, and no linkage of noodle machines, and achieve compactness and uniformity Good, high degree of automation, easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

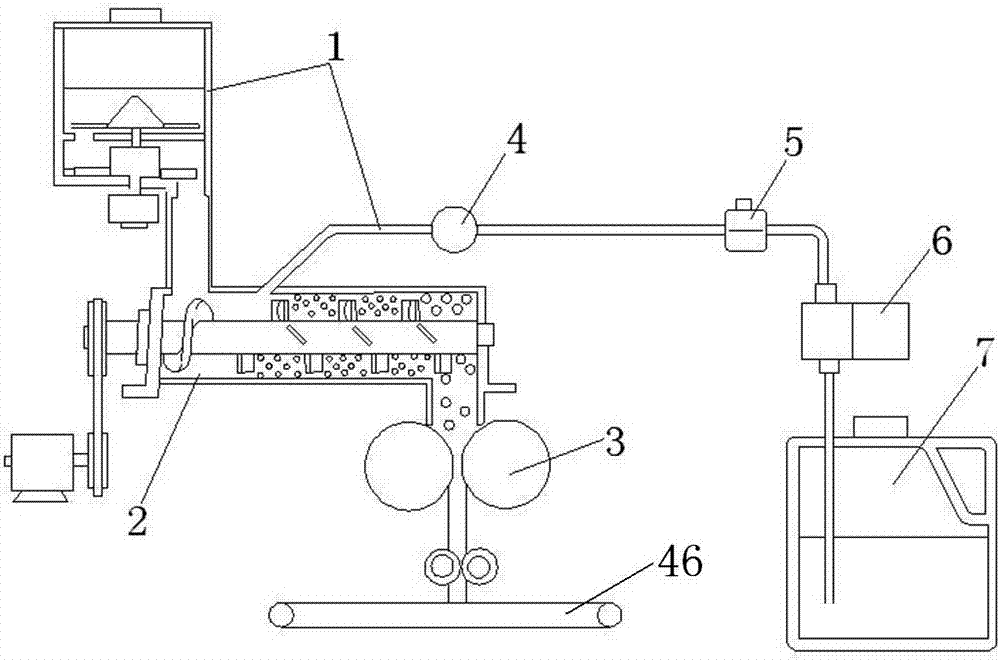

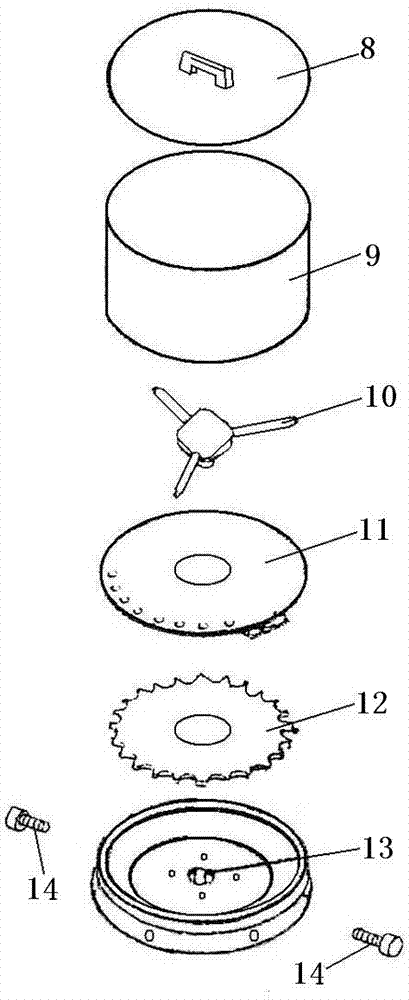

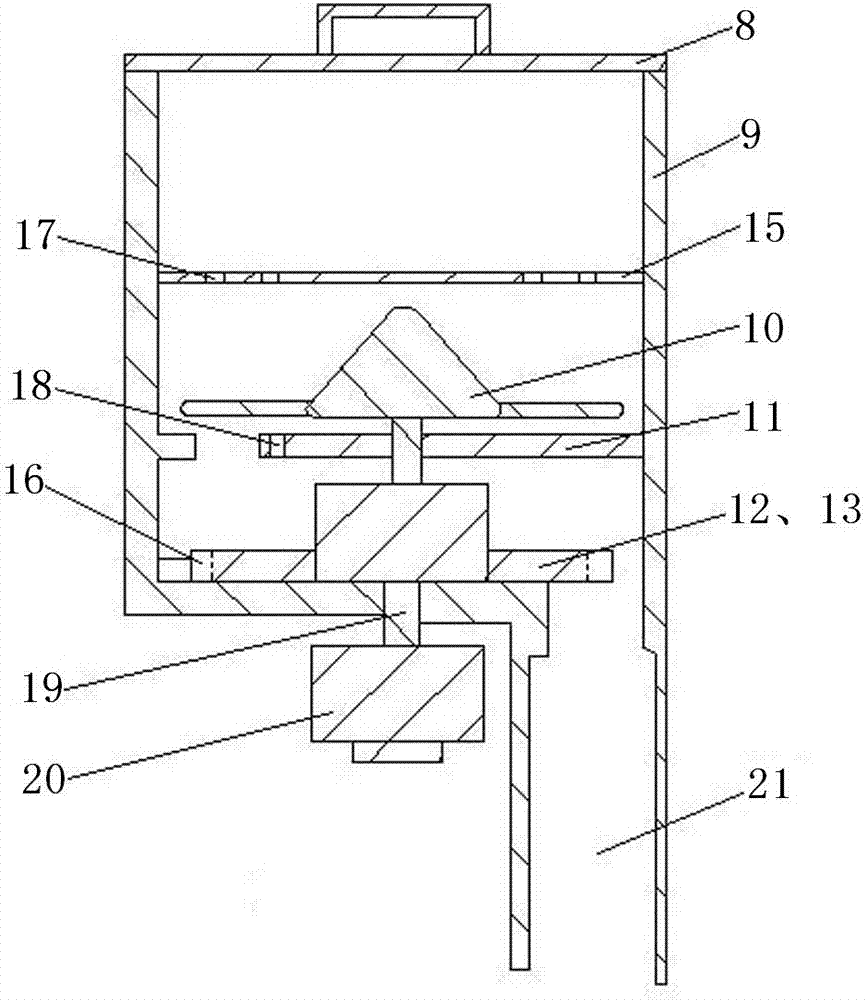

[0026] Example: such as figure 1 As shown, the noodle processing method in this embodiment is realized by an equipment carrier composed of a feeding mechanism 1, an extruding mechanism 2, and a forming and shearing mechanism 3, wherein the feeding mechanism 1 communicates with the extruding mechanism 2 for The raw material is supplied to the inside of the extruding mechanism 2, the extruding mechanism 2 is used to extrude the raw material, the forming and shearing mechanism 3 is connected with the extruding mechanism 2, and is used to shape the raw material extruded by the extruding mechanism 2 cut. The following organizations are contacted to explain the fully automatic and intelligent noodle processing method:

[0027] Such as figure 1 As shown, the feeding mechanism includes a flour feeding mechanism and a water inlet mechanism, and the flour feeding mechanism and the water inlet mechanism are respectively connected to the flour inlet 26 and the water inlet 27 of the extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com