Multi-stage stretching device for plastic flat wires

A stretching device and a technology for plastic flat yarns, applied in the field of plastic weaving, can solve the problems of polluting the environment, unable to produce normally, and easily broken wires, etc., and achieve the effects of anti-aging service life, increasing service life and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

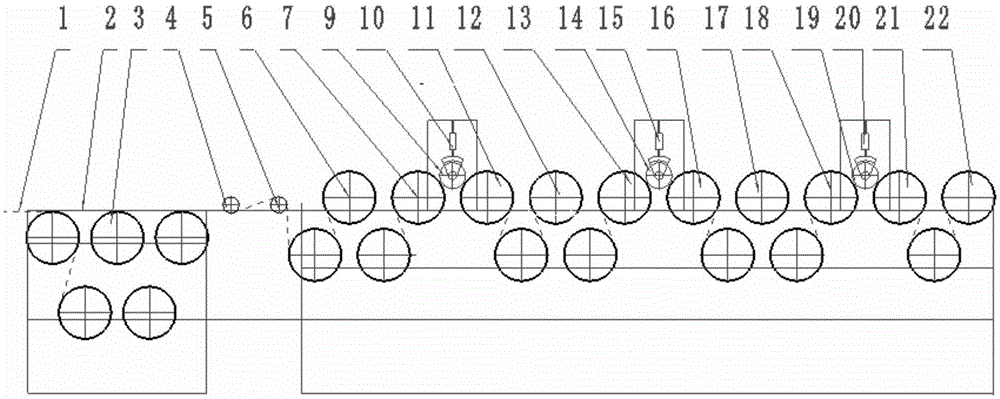

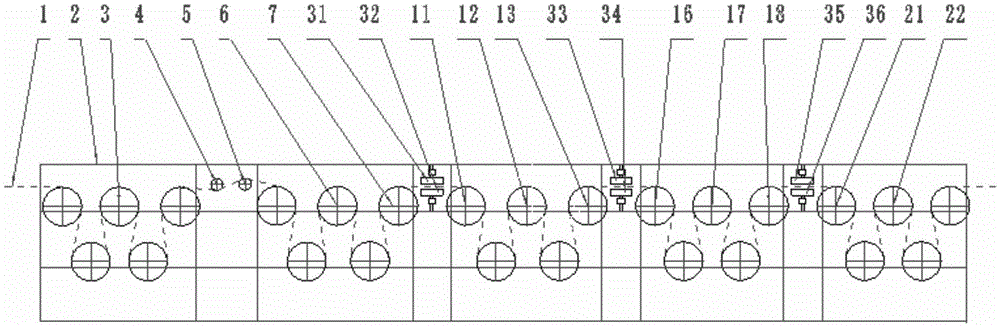

[0023] like figure 1 As shown, a multi-stage stretching device for PET plastic flat yarn includes a fixed frame 2, a film traction roller group 3, a strip cutter 5, a narrow strip filament traction roller group 6, a heating device, a flat filament traction roller group, a power The transmission device and electrical appliances, wherein, the strip cutter 4 is installed between the film traction roller group 3 and the narrow strip filament traction roller group 6, and the heating device includes three parts, which are divided into A heating device, B heating device, and C heating device. A heating device is installed between the narrow strip wire drawing roller group 6 and the first drawing roller group 12 of flat yarn, B heating device is installed between the first drawing roller group 12 of fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com