Method for removing micropollutants in water by activating peroxysulphate through iron electrode

A technology for activating persulfate and persulfate, applied in chemical instruments and methods, water/sewage treatment, special compound water treatment, etc., can solve problems such as low removal efficiency of micro-pollutants, impact on ecosystems, and human health. Achieve obvious cost-effective advantages, fast reaction speed, and avoid the effect of flocculation and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

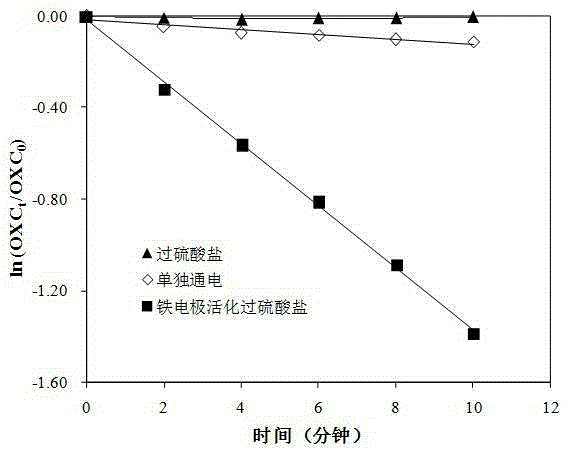

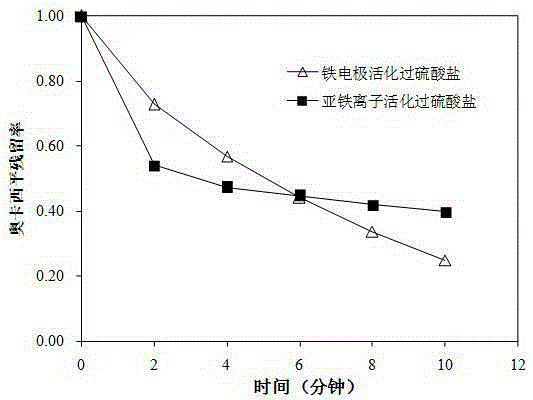

Embodiment 1

[0029] This embodiment provides a method for removing micro-pollutants in water by activating persulfate with an iron electrode. The specific steps are as follows: prepare the aqueous solution containing micro-pollutants to be treated as the solution to be treated, with a volume of 200 mL and a current density of 5.0 mA / cm 2 , the rotating speed of the stirring rotor is 200r / min, the initial oxcarbazepine concentration is 20μM, and the concentration of sodium persulfate is 0.5mM (wherein, M is mol / L, and μM is 10 -6 mol / L, mM is 10 -3 mol / L, the same below), the initial pH of the solution was adjusted to 3.0 with dilute sulfuric acid, and the iron was used as the electrode to conduct electrolysis for 10 minutes, and the removal rate of oxcarbazepine reached 92%.

Embodiment 2

[0035] Prepare the solution to be treated with a volume of 200mL and a current density of 1.6mA / cm 2 , the rotor speed is 200r / min, the initial oxcarbazepine concentration is 20 μM, the potassium persulfate concentration is 0.5mM, and the initial pH of the solution is adjusted to 5.0 with dilute sulfuric acid. The removal rate of oxcarbazepine reached 75% by electrolysis with iron as electrode for 10 minutes.

Embodiment 3

[0037] The volume of the solution to be treated is 200mL, and the current density is 8.3mA / cm 2 , the rotor speed is 200r / min, the initial oxcarbazepine concentration is 20μM, the sodium hydrogen persulfate concentration is 0.5mM, and the initial pH is 7.0. The removal rate of oxcarbazepine reached 82% when the iron was used as the electrode to energize and electrolyze for 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com